Quick Links

- Case Studies

- Our Services

- Online Marketplace

The Complete Guide to Propellers and Their Upkeep on Cruise Ships

Table of Contents

Cruise ship propellers are a vital component of the maritime industry, providing propulsion to large vessels in the open sea. These propellers have evolved, with technological advancements increasing efficiency, reliability, and safety. In this article, we will explore cruise ship propellers.

What are Cruise Ship Propellers, and How Do They Work?

Cruise ship propellers are essential components that enable the vessel to move through the water. The water flows over the edges and creates a pressure difference between the front and back of the propeller blades, which makes a force that moves the ship forward. The faster the propeller rotates, the greater the thrust, allowing the boat to travel faster.

Types of Cruise Ship Propellers

There are several types of cruise ship propellers, including:

- Fixed-Pitch Propellers: These have a fixed blade angle, making them simple and reliable but less efficient.

- Controllable-Pitch Propellers: These propellers allow the angle of the blades to be adjusted while the ship is in motion, making them more efficient.

- Ducted Propellers: These propellers have a shroud or duct around the blades, which increases their efficiency by directing the water flow more precisely.

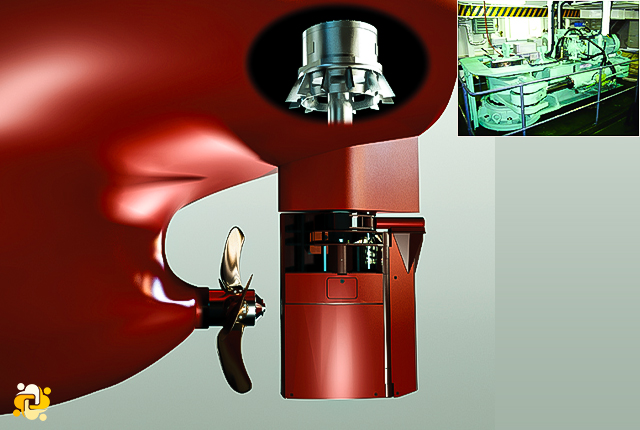

- Azimuthing Propellers: These propellers can rotate 360 degrees and provide excellent maneuverability, making them ideal for large cruise ships.

Cruise Ship Propellers Applications in the Maritime Industries

Cruise ship propellers are vital components in the maritime industry and are used in several applications, including:

- Passenger Transport: Cruise ships use propellers to transport passengers from one destination to another.

- Cargo Transport: Cargo ships rely on propellers to move large volumes of goods across oceans and waterways.

- Fishing: Propellers are used in fishing vessels to tow nets and trawls and to maneuver the boat in the water.

- Military: Propellers are also used in naval vessels, including submarines, destroyers, and aircraft carriers, for propulsion and maneuverability.

Cruise Ship Propeller Maintenance

Propeller maintenance is crucial to ensure cruise ships’ safe and efficient operation. Here are some key points to consider:

- Regular inspections and propeller cleaning are necessary to avoid accumulating marine growth and debris affecting performance.

- The propeller blades and hub should be checked for signs of damage and corrosion.

- Lubrication of the propeller shaft is necessary to reduce friction and prevent wear and tear.

- Regular maintenance of the shaft seals and bearings is essential to prevent water ingress and failure of the propulsion system.

Cruise Ship Propeller Repair Tips to Ensure Long Service Life

Proper propeller repair and maintenance can extend the life of cruise ship propellers. Observe the following advice:

- Propeller repair should only be performed by experienced professionals who use quality materials and follow proper repair procedures.

- Propellers should be balanced to reduce vibration and ensure smooth operation.

- Propeller coatings can protect against corrosion and fouling, leading to reduced performance.

- Routine inspections and repairs can identify minor issues before they become significant problems.

How to Choose the Right Cruise Ship Propeller?

Choosing the correct propeller type can significantly impact a cruise ship’s performance and fuel efficiency. Here are some factors to consider:

- Ship size and weight: The size and weight of the ship can affect the required propeller size and pitch.

- Cruise speed: The ship’s desired cruise speed can determine the propeller’s number of blades and pitch.

- Engine power: The power of the ship’s engine can determine the required size and type of propeller.

- Material: Propellers can be made of different materials, such as bronze, stainless steel, and aluminum, each with advantages and disadvantages.

- Blade design: The blade design can impact the propeller’s efficiency, noise level, and vibration. Different blade designs, such as fixed-pitch or controllable-pitch propellers, may be more suitable for various ships.

How AI is Transforming Cruise Ship Propellers & Maritime Industry?

AI technology is transforming the maritime industry, particularly cruise ship propellers. Here are some ways AI is impacting this sector:

- Predictive Maintenance: Data received from sensors on the ship’s propellers is analyzed by AI algorithms to forecast when maintenance is required, saving downtime and maintenance costs.

- Performance Optimization: By analyzing real-time data, AI can optimize the performance of a ship’s propellers, improving fuel efficiency and reducing emissions.

- Safety: AI can help detect potential issues before they become critical, enhancing safety measures on cruise ships.

Advantages of Using Cruise Ship Propellers

Cruise ship propellers offer numerous advantages over other forms of propulsion. Here are some benefits of using cruise ship propellers:

- Efficiency: Propellers offer excellent fuel efficiency, making them a cost-effective choice for cruise ships.

- Control: Propellers provide excellent control over a ship’s speed and direction.

- Flexibility: Cruise ship propellers are suitable for various vessel sizes and types.

- Reliability: Propellers are a proven technology and are reliable for extended periods of use.

How does a cruise ship propeller work, and what are its advantages and disadvantages?

Like any technology, cruise ship propellers have pros and cons. Here are some pros and cons of using cruise ship propellers:

- Fuel efficiency and cost savings

- Flexibility and suitability for various vessel sizes

- Excellent control over the ship’s speed and direction

- Proven reliability

- Propellers can cause harm to marine life if not designed and maintained correctly.

- Propellers are not ideal for shallow waters or regions with debris, such as ice.

- Propellers require regular maintenance to ensure optimal performance.

- Propellers can be noisy and cause vibration, which can be disruptive to passengers.

The propulsion of big vessels in open water depends on cruise ship propellers, making them an essential component of the maritime industry . Efficiency, dependability, and safety have all improved as a direct result of developments brought about by technological progress. It is vital to execute routine maintenance and ensure the design is sound to ensure optimal operation and reduce the negative influence on marine life.

Related FAQs

How do cruise ship propellers work.

Cruise ship propellers work by converting the rotational force of the ship’s engines into a forward or backward motion. The propellers rotate, creating thrust that moves the vessel through the water.

How many propellers does a cruise ship have?

The number of propellers on a cruise ship varies depending on the size and design of the vessel. Most large cruise ships have two to four propellers.

What materials are cruise ship propellers made of?

Cruise ship propellers are typically made of bronze or stainless steel due to their corrosion-resistant properties and durability.

How are cruise ship propellers maintained?

Cruise ship propellers require regular maintenance, including cleaning, polishing, and repairing any damage or wear. Maintenance is often performed during scheduled dry dock periods.

What is pitch control on cruise ship propellers?

Pitch control allows the angle of the propeller blades to be adjusted, controlling the amount of thrust generated by the propeller. This helps to optimize fuel efficiency and reduce emissions.

How do cruise ship propellers impact marine life?

Cruise ship propellers can cause harm to marine life if not designed and maintained correctly. Proper propeller design and maintenance can help reduce the risk of damage to marine life.

Can cruise ship propellers be noisy?

Yes, cruise ship propellers can be loud and cause vibration, which can be disruptive to passengers. However, advancements in technology have led to quieter and more efficient propellers.

Posted by Orbitshub

Published on 2nd June 2023

Category(s) Maritime

Previous Silent Guardians of the Deep: Exploring the Evolution of Submarine Technology

Next oil spil – catastrophe at sea and its devastating impact on the environment, related posts.

Exploring Ins Vagsheer: A Journey to Remember

Ohio Class Submarine: The Power of Stealth and Precision

[…] Blades: These curved surfaces generate lift and thrust, converting the rotational power from the engine into forward or reverse motion. […]

[…] the propeller as the ship’s paddle, propelling it forward with every turn. We’ll explore the science […]

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

How Big Are Cruise Ship Propellers? (With Images)

How Big Is a Cruise Ship Propeller?

Cruise ships are massive vessels, and their propellers are no exception. These propellers are responsible for propelling the ship through the water, and they can be incredibly large. In this article, we’ll take a closer look at cruise ship propellers, including their size, shape, and function.

We’ll also discuss the different types of propellers used on cruise ships, and how they’re designed to maximize efficiency. By the end of this article, you’ll have a better understanding of these important underwater machines.

Cruise ships are massive vessels that can weigh up to 200,000 tons and carry thousands of passengers. In order to move such a large ship, cruise ships use propellers to generate thrust. The size of a cruise ship propeller is determined by a number of factors, including the weight of the ship, the speed at which it needs to travel, and the water conditions in which it will be operating.

Types of Cruise Ship Propellers

There are two main types of propellers used on cruise ships:

- Screw propellers are the most common type of propeller used on cruise ships. They consist of a central shaft with a series of blades attached. As the shaft rotates, the blades create a vortex that pulls the ship forward.

- Azipod propellers are a newer type of propeller that is becoming increasingly popular on cruise ships. Azipods are mounted on a pod that can rotate 360 degrees, allowing the ship to maneuver more easily in tight spaces.

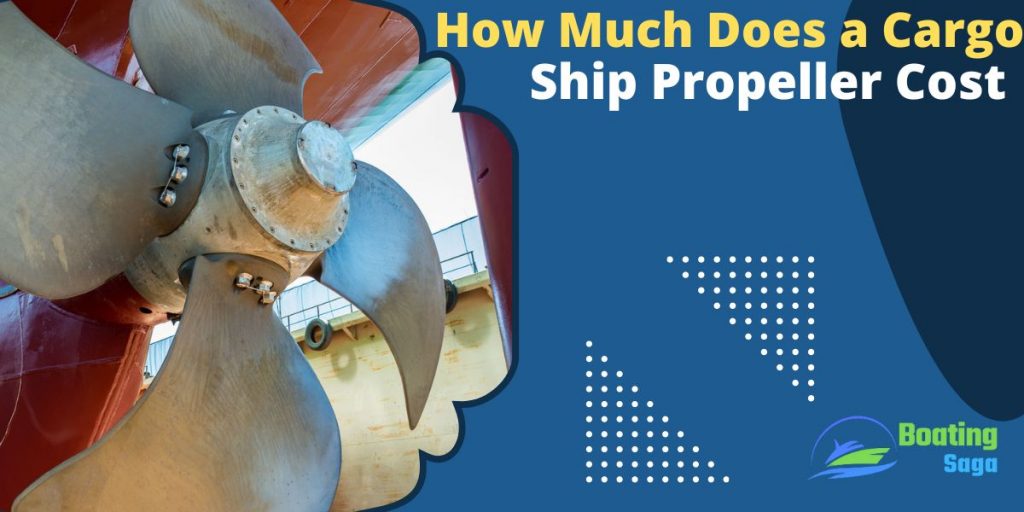

Size of Cruise Ship Propellers

The size of a cruise ship propeller varies depending on the size of the ship. The smallest cruise ship propellers are about 10 feet in diameter, while the largest propellers can be over 20 feet in diameter. The following table provides a general overview of the size of cruise ship propellers:

| Ship Size | Propeller Diameter | |—|—| | Small ( 200,000 tons) | 20-25 feet |

Cruise ship propellers are an essential part of these massive vessels. They allow cruise ships to travel across the oceans, carrying thousands of passengers to their destinations. The size of a cruise ship propeller is determined by a number of factors, including the weight of the ship, the speed at which it needs to travel, and the water conditions in which it will be operating.

Factors Affecting Cruise Ship Propeller Size

The size of a cruise ship propeller is determined by a number of factors, including the ship’s weight, speed, and maneuverability.

- Ship weight: The heavier the ship, the larger the propeller needs to be in order to generate enough thrust to move it through the water.

- Speed: The faster the ship needs to travel, the larger the propeller needs to be in order to generate enough thrust to maintain that speed.

- Maneuverability: The more maneuverable the ship needs to be, the larger the propeller needs to be in order to provide the necessary turning force.

In addition to these factors, the size of a cruise ship propeller is also affected by the type of propeller used. There are two main types of propellers used on cruise ships:

- Screw propellers: Screw propellers are the most common type of propeller used on cruise ships. They consist of a number of blades that are attached to a central shaft. As the shaft rotates, the blades create a vortex that pulls the ship through the water.

- Waterjets: Waterjets are a relatively new type of propeller that is becoming increasingly popular on cruise ships. They consist of a pump that draws water in from the front of the ship and then forces it out through a nozzle at the back of the ship. The high-pressure water jet creates a thrust that propels the ship forward.

The size of a cruise ship propeller can vary significantly, from as small as 10 feet in diameter to as large as 20 feet in diameter. The average size of a cruise ship propeller is around 15 feet in diameter.

The following table provides a more detailed overview of the factors that affect cruise ship propeller size:

| Factor | Effect on Propeller Size | |—|—| | Ship weight | Increased weight requires a larger propeller | | Speed | Increased speed requires a larger propeller | | Maneuverability | Increased maneuverability requires a larger propeller | | Type of propeller | Screw propellers require a larger propeller than waterjets |

Factors Affecting Propeller Size 1

The weight of a cruise ship is one of the most important factors that determines the size of its propeller. The heavier the ship, the more thrust it needs to generate in order to move through the water. This means that a cruise ship with a heavier weight will require a larger propeller than a cruise ship with a lighter weight.

The weight of a cruise ship is determined by a number of factors, including the size of the ship, the number of passengers and crew on board, and the amount of cargo that is being carried. The weight of the ship’s superstructure, engines, and other equipment also plays a role.

The weight of a cruise ship can vary significantly, from as little as 10,000 tons to as much as 200,000 tons. The average weight of a cruise ship is around 100,000 tons.

The size of a cruise ship propeller is directly proportional to the weight of the ship. This means that a cruise ship with a weight of 100,000 tons will require a propeller that is approximately twice as large as a cruise ship with a weight of 50,000 tons.

Factors Affecting Propeller Size 2

The speed of a cruise ship is another important factor that determines the size of its propeller. The faster the ship needs to travel, the more thrust it needs to generate in order to maintain its speed. This means that a cruise ship with a higher speed will require a larger propeller than a cruise ship with a lower speed.

The speed of a cruise ship is determined by a number of factors, including the power of the ship’s engines, the size of the propeller, and the amount of resistance that the ship is experiencing from the water. The speed of a cruise ship can vary significantly, from as little as 10 knots to as much as 30 knots. The average speed of a cruise ship is around 20 knots.

The size of a cruise ship propeller is directly proportional to the speed of the ship. This means that a cruise ship with a speed of 20 knots will require a propeller that is approximately twice as large as a cruise ship with a speed of 10 knots.

Factors Affecting Propeller Size 3

The maneuverability of a cruise ship is another important factor that determines the size of its propeller. The more maneuverable the ship needs to be, the larger the propeller needs to be in order to provide the necessary turning force.

The maneuverability of a cruise ship is determined by a number of factors, including the size of the ship, the number of propellers, and the type of propellers. The size of the ship plays a major role in

How big is a cruise ship propeller?

Cruise ship propellers can range in size from 10 to 20 feet in diameter. The largest propellers are found on the largest cruise ships, such as the Oasis of the Seas and Symphony of the Seas, which have propellers that are each over 20 feet in diameter.

What is the purpose of a cruise ship propeller?

The propellers on a cruise ship are used to propel the ship through the water. They are typically located at the stern of the ship and are powered by the ship’s engines. The propellers turn the water in a circular motion, which creates thrust and moves the ship forward.

How many propellers does a cruise ship have?

Most cruise ships have three propellers, but some larger ships have four or more. The number of propellers on a ship depends on the size of the ship and the amount of thrust that is needed to propel it.

What is the difference between a cruise ship propeller and a ship propeller?

Cruise ship propellers are typically larger and more powerful than ship propellers. This is because cruise ships are much larger than ships and require more thrust to propel them through the water. Cruise ship propellers are also typically made of different materials than ship propellers. Cruise ship propellers are often made of stainless steel or bronze, while ship propellers are often made of cast iron.

How often do cruise ship propellers need to be replaced?

Cruise ship propellers typically need to be replaced every 5 to 10 years. The lifespan of a propeller depends on a number of factors, including the type of material it is made of, the amount of wear and tear it experiences, and the operating conditions of the ship.

What happens if a cruise ship propeller breaks?

If a cruise ship propeller breaks, it can have a significant impact on the ship’s performance. The ship will lose power and may be unable to maintain its speed. In some cases, a broken propeller can even cause the ship to lose control.

How do cruise ship propellers work?

Cruise ship propellers work by turning the water in a circular motion, which creates thrust and moves the ship forward. The propellers are typically located at the stern of the ship and are powered by the ship’s engines. The engines turn a shaft, which in turn turns the propellers. The propellers are designed to be as efficient as possible, so they are typically made of lightweight materials and have a smooth, streamlined design.

What are the different types of cruise ship propellers?

There are two main types of cruise ship propellers: fixed pitch propellers and variable pitch propellers. Fixed pitch propellers have blades that are fixed in place, while variable pitch propellers have blades that can be adjusted to change the pitch. Variable pitch propellers are more efficient than fixed pitch propellers, but they are also more expensive.

How much does a cruise ship propeller cost?

A cruise ship propeller can cost anywhere from $1 million to $10 million. The cost of a propeller depends on a number of factors, including the size of the propeller, the type of material it is made of, and the operating conditions of the ship.

the size of a cruise ship propeller is a significant factor in determining the ship’s speed, efficiency, and maneuverability. The larger the propeller, the more thrust it can generate, which in turn allows the ship to move faster. However, larger propellers are also more expensive and require more power to operate. As a result, cruise ship designers must carefully balance the need for a large propeller with the other factors involved in ship design.

Here are some key takeaways from this article:

- The size of a cruise ship propeller is typically between 10 and 20 feet in diameter.

- The larger the propeller, the more thrust it can generate, which in turn allows the ship to move faster.

- Larger propellers are also more expensive and require more power to operate.

- Cruise ship designers must carefully balance the need for a large propeller with the other factors involved in ship design.

Author Profile

Latest entries

- January 19, 2024 Hiking How to Lace Hiking Boots for a Perfect Fit

- January 19, 2024 Camping How to Dispose of Camping Propane Tanks the Right Way

- January 19, 2024 Traveling Information Is Buffalo Still Under Travel Ban? (Updated for 2023)

- January 19, 2024 Cruise/Cruising Which Carnival Cruise Is Best for Families?

- CruiseMapper

- Ships and Lines

Cruise Ship Engine Power, Propulsion, Fuel

These are some of the most interesting cruise ship technology-related data and facts - engines , power , marine propulsion systems , fuel consumption of cruise ships , and something about pollution (in-article navigation links).

In 2020, IMO (International Maritime Organization) implements its global 0,5% sulfur cap on marine fuels. If not using scrubbers (pollution control devices), owners of older vessels must use as ship fuels either MGO (marine gas oil), ECA Category Fuels (low sulfur MGO), new modified fuels and blends, LNG (liquefied natural gas) or electric/battery power . Each fuel option is based on vessel type and age, routes/itineraries and powerplant. Most newbuild passenger ships are LNG-powered . World's largest seaports plus numerous smaller ports already have installed shoreside power capabilities providing shore-to-ship power supply to berthed vessels. In many ports, shorepower is in addition to LNG bunkering capabilities.

Cruise Ship Engine

Without a source of power, these huge cruise vessels would be nothing more than drifting aimlessly hotels. A large number of older ships use diesel reciprocating engines for generating power for propulsion. Cruise ship engine power is supplied through the transmission to the propeller shafts. These transmissions determine the revolutions of propellers. Modern ships use either diesel-electric engines or gas turbines as a source of power for propulsion, and for ship's systems. Some of the larger ships depend on two power sources - one for electrical power and one for propulsion.

Gas turbine engines (being aero-derivative) generate heat which is transformed from mechanical energy into electricity. To achieve this, compressed air is fired in a combustion chamber. Hot exhaust is made over a turbine that spins to drive mechanically a shaft. The power can be used to spin the generators. The same way works diesel-electric engines, yet they use a direct drive system, not a turbine. The output shafts, to produce electrical power, are connected to generators.

Both engine types need a lot of fuel. Cunard QE2 , for example, consumes daily 380 tons of fuel when traveling at 29 knots speed and carries fuel enough to sail for 12 days. Usually, ships fill up at various seaports and use fueling barges as floating gas stations. Vessels use lower-grade diesel which tends not to burn as purely as diesel-powered road-going vehicles.

All ships rely on propellers/screws to be pushed through the water, providing forward and reverse motion. Airplanes, for example, require tremendous propeller speeds to provide the forward motion, but ship propellers don't need to turn so fast and rely on torque power. Therefore, ships travel slowly and rarely top 30 knots (for more info follow our speed-link above).

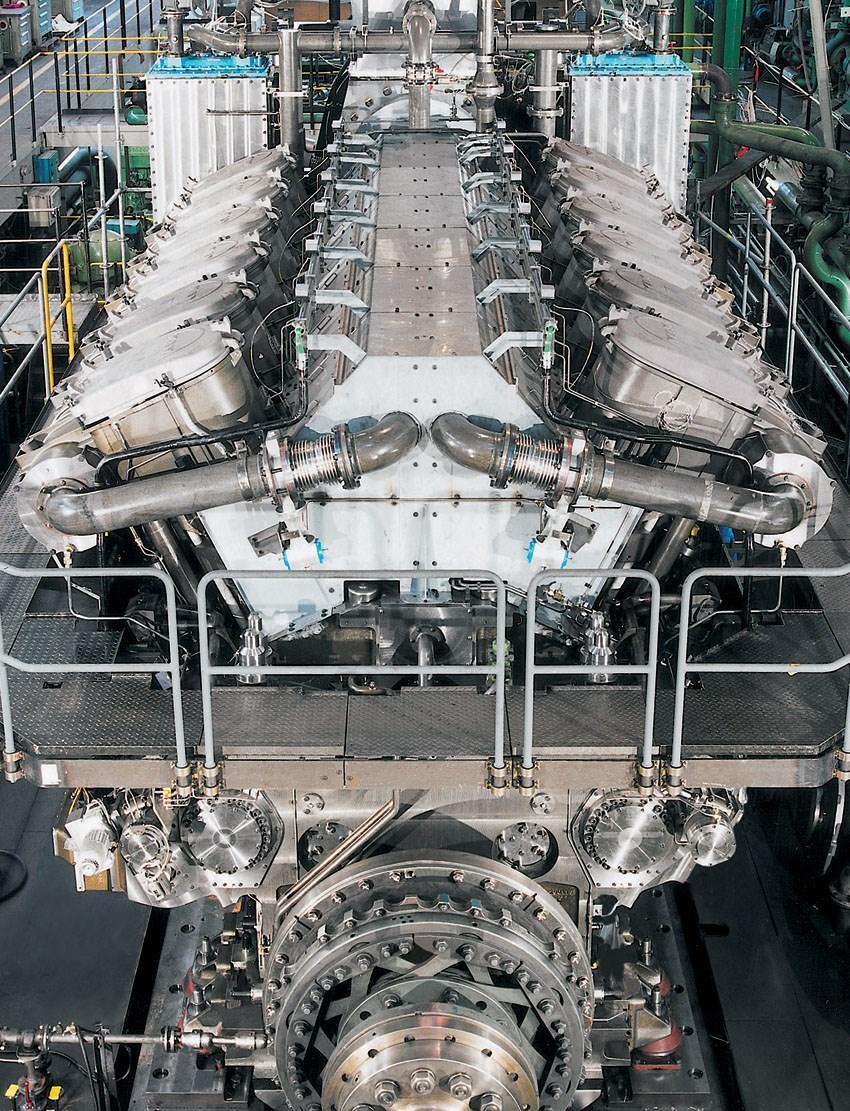

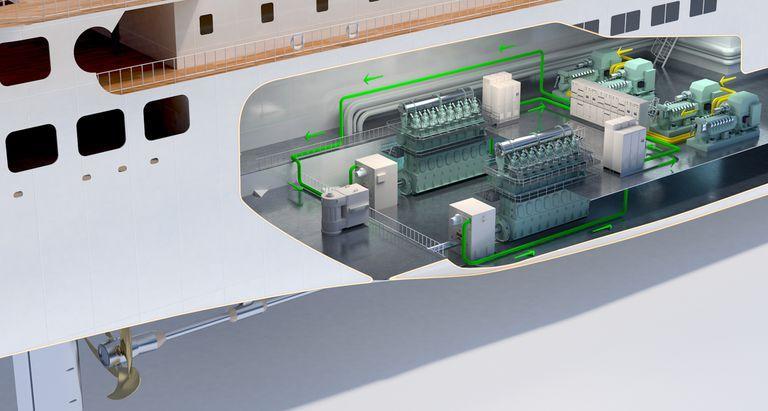

Cruise ship engine room

The basic detail about the cruise ship engine room is its location. For stability, the ship's heaviest weights are at its lowest possible deck, and usually, engines are mounted above the keel. Ship's lowest decks are almost entirely full of machinery. An area creating enough power for driving such an enormous vessel through water needs to be really big - very often engine rooms occupy at least three decks. Rather than long halls stretching the length of hulls, machinery is almost always divided into smaller compartments - one for the main engines, another for the heating/air-conditioning system. This compartmentalization is for safety reasons. If a penetration to the hull or fire happens, multiple compartments help contain the damage. The next photo shows the engine room of RCI's Oasis-Class vessels.

Rarely, engines are not placed at the ship's bottom. RMS Queen Mary 2's four main diesel engines are above the keel, with two smaller gas turbines on top-deck (aft of the funnel). It was not unusual for older liners to have 2 engine rooms. Gradually, technology allowed the consolidation of these spaces. However, current maritime legislation requires vessels to have equipment duplication and 2 engine rooms.

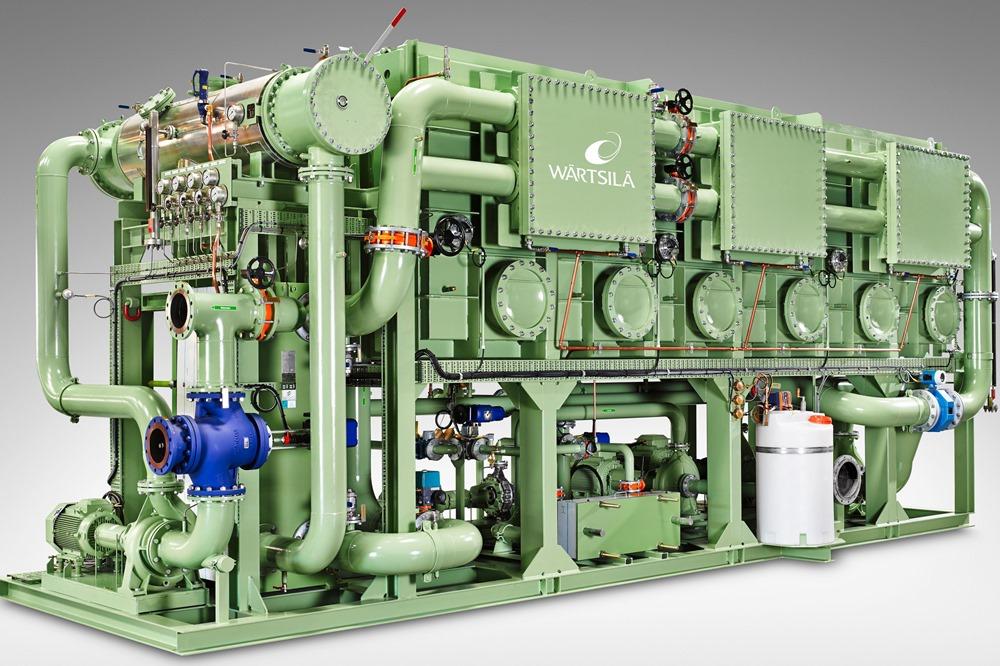

In May 2015, Wartsila Corporation and Carnival Corporation partnered to optimize cruise ship engine room operations of all 101 ships across the corporation's 9 brands. The deal was signed by Micky Arison (Carnival's Chairman) and Bjorn Rosengren (Wartsila's President and CEO). The plan included installing Wartsila's latest marine solutions, first tested on several Carnival Cruise Line vessels in pilot projects. The new systems and technologies included engine control and monitoring systems, safety and fuel efficiency equipment.

Wartsila's "Asset Performance Optimization Solution" package allows obtaining optimal performance from Wartsila marine diesel engines, recommends how to deal with potential issues, maximizes ship performance, ensures full-capacity systems operations, increases the predictability of fuel management and maintenance needs. Wartsila's fuel engine package was specifically designed to reduce fuel consumption.

Wartsila Marine technologies aim to optimize ship performance, but also allow to locate deviations from normal parameters of equipment and engines. This allows emerging problems and engine fault sources to be fixed before they occur.

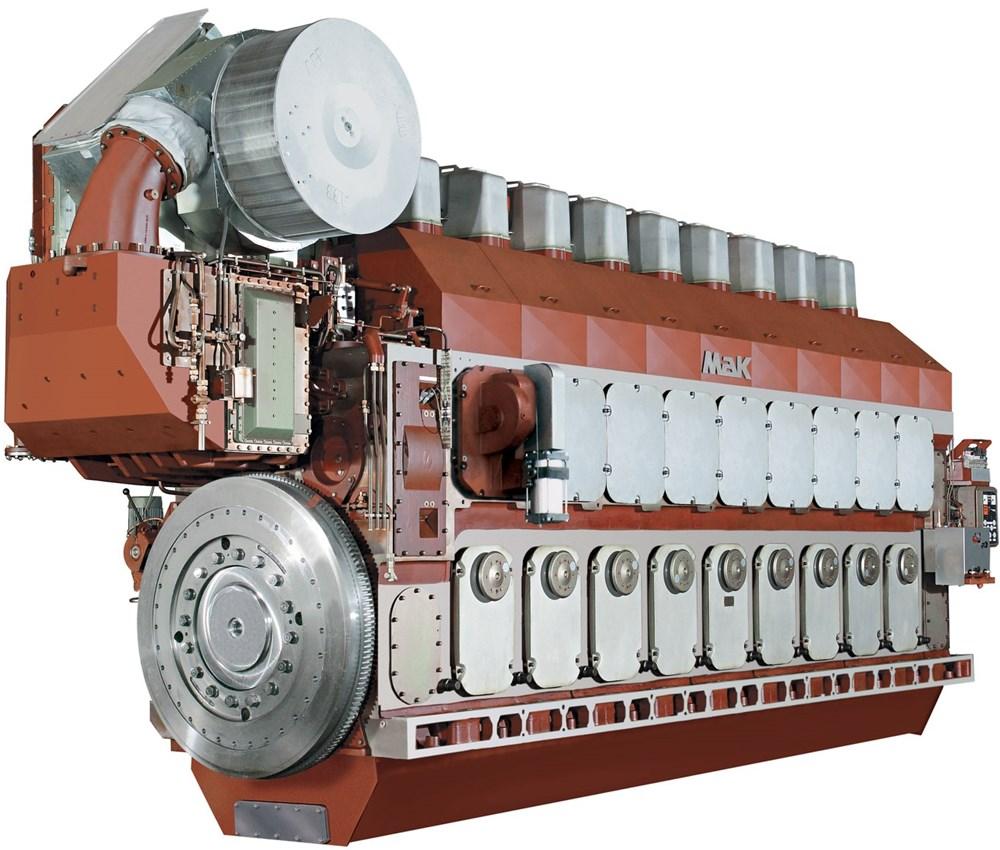

Conventional diesel cruise ship engine

Today's direct-drive diesels feature one main advantage - the option to use a shaft generator, which is a device using the circular motion of the propeller shaft in order to generate the electricity needed for hotel services, like cooking and lighting.

Shaft generators can be used only while the ship is moving with a fairly constant cruising speed. This is what the NCL Epic cruise ship engine looks like:

Diesel-electric cruise ship engine

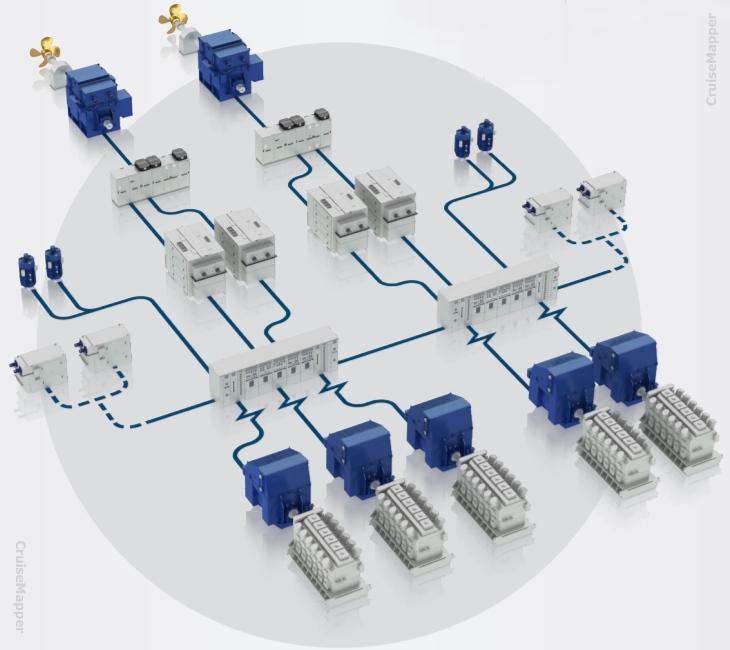

Almost all new ships feature a diesel-electric propulsion form. On these ships, main engines are not connected to propeller shafts, and instead of it they are directly connected to big generators in order to produce electricity, which is sent in turn to electric motors, that then power and help turn the propellers. The main advantage of the diesel-electric cruise ship engine systems is efficiency as they allow main engines to operate near the most efficient speed, no matter if the ship is moving at 5 or 25 knots.

Losing electrical power is devastating to ships. Main engines and generators require electricity and it's needed to keep them going. Pumps that are driven electrically take in cold ocean water to cool the engines and electrical pumps get fuel from fuel tanks and supply it to the engine. Electrical power is vital for many operational functions - without it, ships come to a halt.

Large equipment (propulsion motor, bow thrusters) requires electricity of high voltage. As for smaller machinery (cabin lights, galley equipment), the electricity goes through the transformer and is thus stepped down into lower voltage. Large cables snake through all the ships to distribute electrical power. They carry power from generators to switchboards, through passageways, public rooms, crew and passenger cabins. Cabling can be a weak point in the distribution system. If the electrical cables aren't truly redundant, even ships that feature two engine rooms suffer power failure.

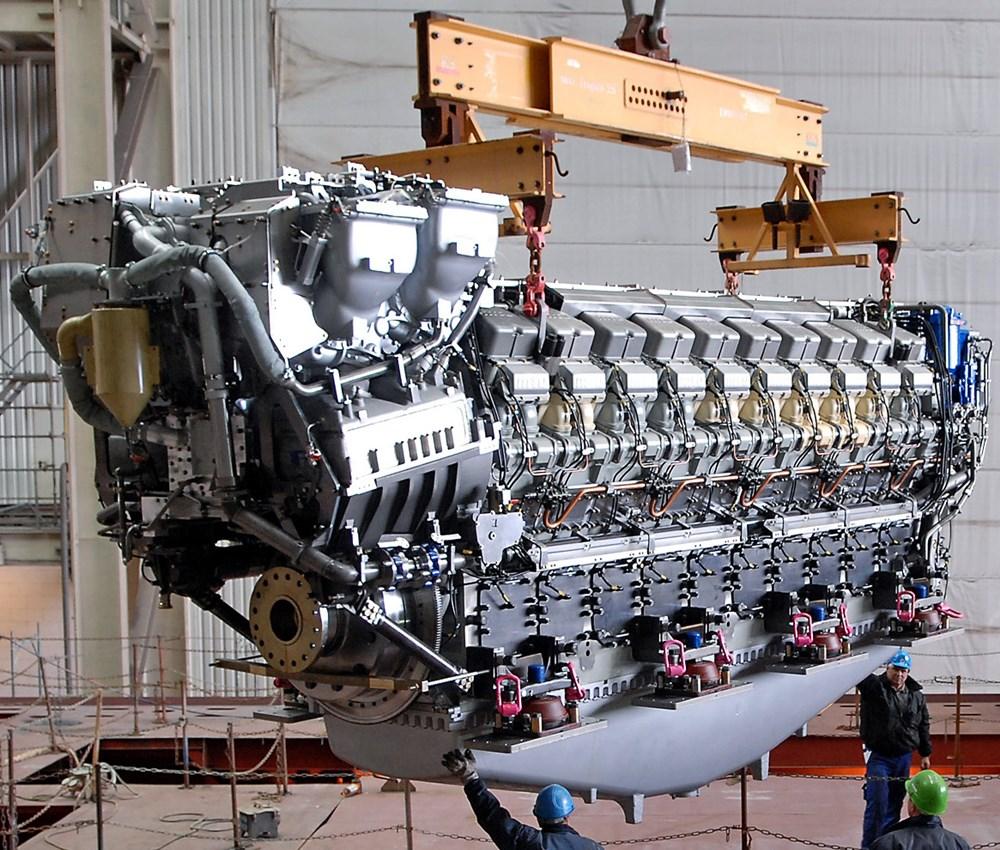

While ships are docked, generators and main engines produce more power than needed. They are turned off in port, and smaller generators supply "hotel" loads (lights, air-conditioning, galley, etc.). Moving through water takes up the vast majority of the ship's power needs - about 85% of all the diesel-electric powerplant production is consumed by the propulsion system. The above photo is of the Vista-class Carnival cruise ship engine room. The engine type is "MAN 2 times; 14V48/60CR" (common-rail diesel injection system):

Cruise ship Emergency Generators

All ships are supplied with emergency generators to maintain vital electrical power. Backup generators are located higher up and also outside engine room spaces to isolate them from damage or fire.

Big ships require much power, so they might have more than one emergency generator. Despite that, they don't have the capacity of main generators and engines, don't produce electricity enough to move the ship, and can't supply all the power needed in ports, because of constraints in space.

Emergency generators are instead used only for essential navigation systems - crucial communication equipment, critical pumps in the engine room, emergency lighting. Should they also fail, vessels are required to have a battery backup. 24 hours of power are at least provided by battery rooms to the smaller emergency equipment list.

Probably you've heard about Carnival cruise ship accidents related to power failures in 2013. At our Carnival Fun Ship 2.0 upgrades link you can learn how CCL battled with this "unmaintained ships" image and implemented revolutionary new technology initiatives fleetwide - including an additional emergency backup generator on each of their vessels.

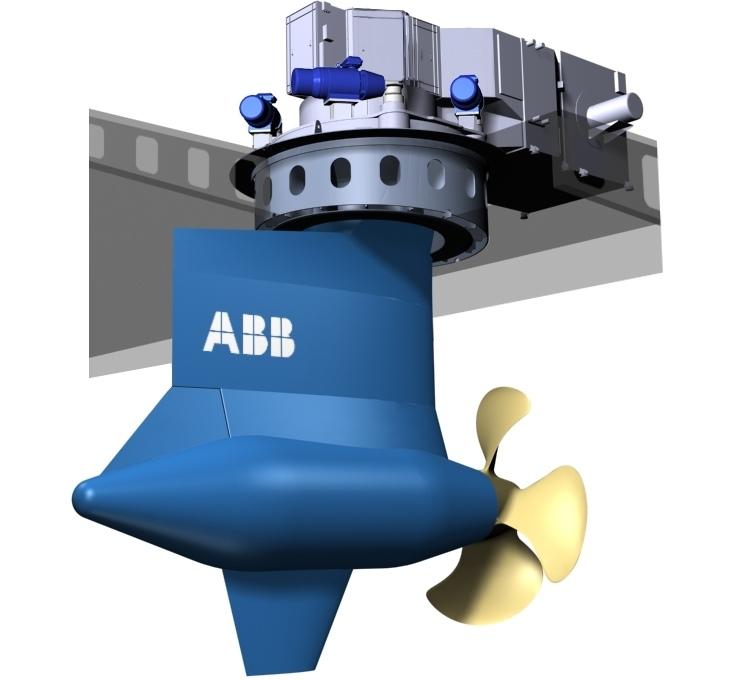

Cruise Ship Propulsion

The new cruise ship propulsion systems ABB Azipods XO (below photo) are more fuel-efficient than traditional systems, also providing better maneuverability, maximizing speed, reducing bad emissions, which as a whole optimizes ship's performance and enhances passenger safety.

ABB Azipod propulsion systems have a major impact on the vessel's operating efficiency - reducing energy consumption and bad emissions by up to 20%.

In 2019, ABB signed a deal with Oldendorff Carriers (1921-founded, Germany's largest bulk shipping company with a fleet of ~700 ships) for the supply and installation of Azipod propulsion systems on two newbuild carriers. Both self-unloading dry bulk vessels were China-built (by Chengxi Shipyard Co Ltd / subsidiary of CSSC) and scheduled for deliveries in 2021. Each vessel was fitted with two Azipods (power output 1,9 MW per unit) plus various related electric and digital solutions (powerplant, diesel-electric generators, bow thruster motors, transformers, switchboards, power management system, ABB Ability global ABB real-time monitoring).

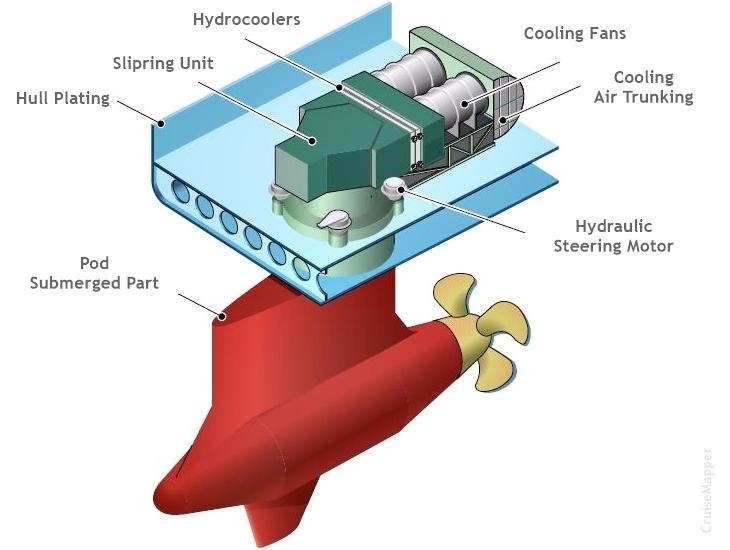

Azipod cruise ship propulsion system

Azipod cruise ship propulsion system is situated outside the hull in the aft of the ship. Azipod turns in all directions (360 degrees) by a rudder, providing thrust in any directions, not possible for conventional systems.

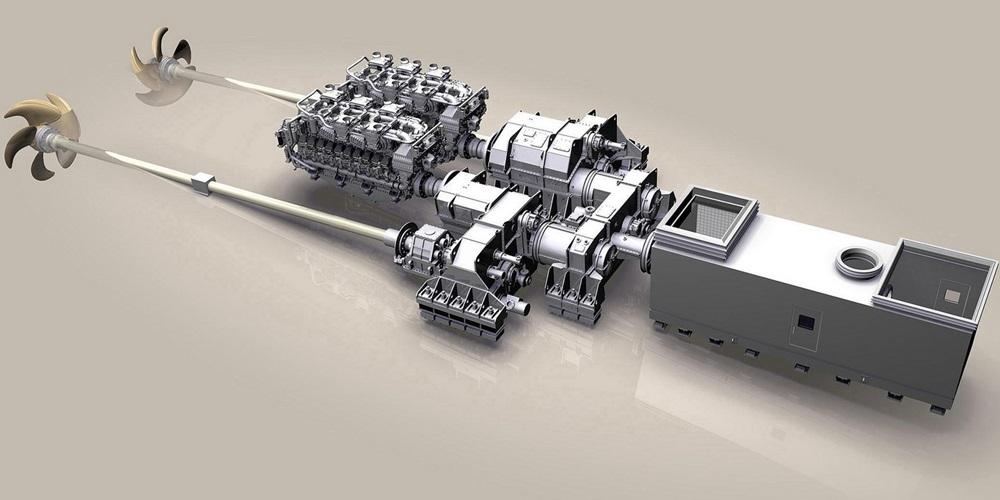

See at the first photo at right RMS Queen Mary 2 's propulsion system scheme.

QM2's Azipod is actually an electric propulsion system consisting of the following main components:

- Propulsion motor - used to produce or drive thrust. The propeller's rotating is powered by an electric motor.

- Supply transformer - power produced by generators is 6600 KV, which is stepped down to the necessary voltage by supply transformer and is provided to the motor in the pod.

- Frequency controller - used to change the frequency of supplied power so that the rotating motor speed can be controlled.

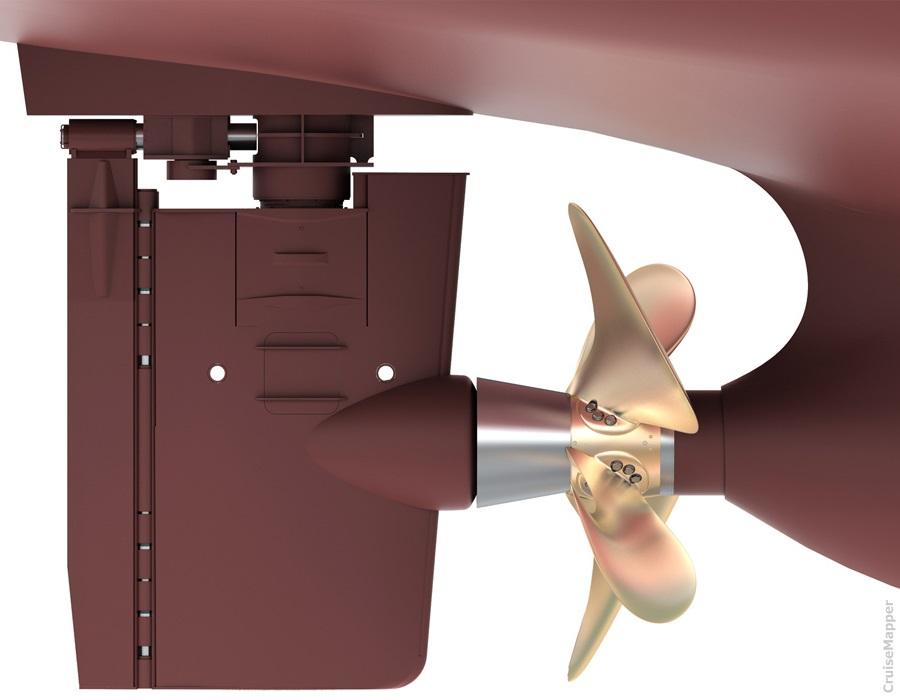

Azipod marine ship propulsion is a combination of both steering and propulsion systems. Conventional marine propulsion systems use a two-stroke engine connected to a shaft, that passes through a stern tube and shaft tunnel to connect to the propeller outside the hull in the ship's aft/stern. This system's steering is done by a rudder (in the propeller's aft).

The above photo shows Oasis-class ship propulsion Azipods (2 units) before being mounted onto the hull. The next photo shows the Azipods (both units) mounted on the hull.

The 3rd Oasis-class ship - Harmony of the Seas, is currently the most technologically advanced and energy-efficient cruise vessel ever built. It is equipped with a new-generation exhaust gas cleaning system (multi-stream scrubbers) and also features a hull lubrication system allowing the ship to float on air bubbles (created around the hull) thus reducing drag and increasing fuel efficiency.

However, the steering and propulsion systems in Azipod arrangement, are combined into one part and the system consists of a propeller (driven by an electrical motor) turned by a rudder connected to the azipod system. The motor is inside the sealed pod and connected to the propeller.

The following YouTube video is about ABB Azipods installed on the new Genting Hong Kong vessels (Star Cruises' new ships and on Crystal Cruises' polar-class boats).

These ships incorporate a complete ABB propulsion - Azipods, electric power plant, computer automation, and software. Crystal cruise ships are powered by two "Azipod D" units allowing navigation in polar destinations. Each of the Star Cruises "Global-Class" vessels have three "Azipod XO" thrusters. All ships have installed ABB's "Intelligent Maneuvering Interface" and the "OCTOPUS" software optimizing fuel consumption and energy management. All these ships were constructed by the German shipbuilder MV Werften. Currently, almost 2/3 of all large-sized cruise vessels, icebreaking ships, and high ice-class cargo ships are with Azipod propulsion.

Advantages of Azipod propulsion marine systems

- A lot of space is saved by the Azipod cruise ship propulsion system in the engine room - there is no propeller, engine, shafting or other arrangements. This saved space can be used for storing cargo.

- Great maneuverability - the propeller can turn in all directions and enables crash maneuvering stop distance that is better than the conventional systems.

- Azipod cruise ship propulsion system can be placed below the ship's height and provide more efficiency than conventional systems.

- In case the ships have large breadth, two (or more) azipod systems, independent from one another, can be used to provide subtle maneuvering.

- Side thruster's use is eliminated as pods can be used to provide side thrust.

- Low lube oil and fuel consumption.

- Lower vibrations and noise than conventional systems.

- Because emissions are low, it's environment-friendly.

Disadvantages of the Azipod marine propulsion

- It requires great initial cost.

- Many diesel generators are needed for producing power.

- The power produced by the motor is limited - the maximum available power now is 21 MW.

- Azipod cruise ship propulsion systems can't be installed in heavy cargo ships that need large motors and a lot of power.

Royal Caribbean Quantum-class cruise ships propulsion

In April 2012 ABB made a USD 60-million contract to provide the Azipod propulsion systems for the new Royal Caribbean ships of the Quantum-class (Quantum, Anthem, Ovation) and Quantum Plus-class (Pulse, Passion). The former name of this vessel design was "Project Sunshine". Builder is Meyer Werft (Papenburg, Germany).

ABB also supplies the power generation, distribution systems, bow thrusters, and of course, the 2 x 20,500 kW propulsion Azipod XO units (at the photo at right), transformers and drives.

NCL Epic ship pod-propulsion

When entering service in 2004, the Cunard's QM2 was the biggest in the world at 150,000 GR tonnes. Her designer Stephen Payne showed the advantages of pod-propulsion giving vessels increased maneuverability. The propellers (screws) of the QM2 ship are mounted on the pods which rotate 360 degrees and provide advanced maneuverability. He made the choice to put pods - though relatively new and yet untested for big ships. Royal Caribbean vessels of Oasis, Freedom, and Voyager classes have pod-propulsion as many other big ships, which is opposed to the fixed traditional screws which push in one direction only.

An interesting fact about cruise ship propulsion is that Norwegian Epic doesn't have pods, though slightly bigger than Queen Mary 2 (at 153,000 GR tonnes), because of NCL concerns about the new technology. Some of the lines (including Celebrity and Cunard) have suffered vessel breakdowns due to pod-bearing failures. Lots of voyages had to be canceled, extensive dry-docking periods were required for pod bearings to be replaced, and NCL didn't want to take the risk.

Currently, NCL Norwegian Epic has two rudders with conventional non-Azipod screws. But how does she manage to maneuver if they can push in one direction only? One option is to make them bigger and more effective when maneuvering, another is to add additional mini-pods or install full-sized pods. Only time will tell if any of these will actually ever happen.

Rolls-Royce cruise ship propulsion system "Promas Lite"

In November 2013, the manufacturing giant Rolls-Royce upgraded Hurtigruten's ship MS Richard With its new "Promas Lite" propulsion system (integrated propeller-rudder system). This is an older ship, and Promas Lite was the perfect choice as it is a combined "propeller-rudder" system increasing the efficiency of older passenger vessels with lesser tonnage. The upgrade significantly reduced Hurtigruten's operating costs on this vessel. The improved propeller efficiency was estimated to be between 11-14% at a cruising speed of 15 knots (17 mph / 28kph).

Promas propulsion integrates propeller, hubcap, rudder bulb and the rudder into a single unit which can increase propulsion's efficiency by 3-8% (1-screw vessels) and by 2-6% (2-screw vessels). It also improves maneuverability, reduces fuel consumption and bad emissions. The new modular technology allows efficient and cost-effective custom-made systems to be built up from various existing and standard parts - mooring winches, anchor cable lifters, warping heads.

Hurtigruten was compensated with ~80% of its total investment in Promas Lite marine propulsion upgrades as the Norwegian Government has this NOx fund encouraging shipowners and operators to upgrade their vessels and invest in new marine technologies that reduce NOx emissions. The Promas Lite propulsion future clients, besides passenger ships, are marine vessels like fishing and freighter ships.

After Norwegian Spirit (the first ship in NCL fleet with installed Promas Lite in 2011), in May 2014 the Star Cruises ship SuperStar Virgo became Southeast Asia's first passenger liner with RR's Promas Lite propulsion. Fincantieri used Promas Lite propulsion for all Viking Ocean liners.

Cruise Ship Power

The cruise ship engine power is responsible for driving propellers, and the other possibility is producing electricity that is used subsequently to drive propellers. The engine's effectiveness depends not only on the design but also the ship's shape, weight, and size. Power is measured in horsepower traditionally - one horsepower equals 746 watts. The next photo shows the world's largest passenger ships' engine that powers each of the Royal Caribbean Oasis-class vessels.

Marine steam engines

The cruise industry began in 1844, when ships were propelled by steam engines, performing the driving of propellers by using steam as working fluid. The largest passenger steamship (before hitting an iceberg on April 14, 1912) was the Titanic, powered by both reciprocating engines and turbines, able to generate 50,000 horsepower (37 megawatts).

Marine diesel engines

Usually, ships are powered by four or five generator sets (medium-speed, 500 revolutions per minute), fueled by diesel and creating 8-10 MW energy each. The power density of marine diesel medium-speed engine is 80 kilowatts per cubic meter. Ships that use diesel engines are required to carry exhaust-treatment systems and catalytic-reduction equipment to reduce the environmental impact.

Marine nuclear power engines

The building of the US first and only merchant nuclear-powered ship was commissioned in the 1950s by President Eisenhower. Of total cost $46.9 million, on the fuel core and nuclear reactor was spent more than $28 million. The ship operated only for five years (1965-1970) but due to the high running costs, its service was terminated.

Marine gas turbines

The first company that fitted cruise vessels with gas turbines, was Royal Caribbean. Gas turbines are greener than diesel engines and allow ships to sail with reduced inventory and smaller maintenance crew. Gas turbines drive generators which in turn provide electricity to propeller motors. They recover heat from gas turbines' exhaust, which then is used to produce the electricity needed for onboard services (air conditioning, water heating).

Rolls Royce is the manufacturer of the world's largest GAS marine turbine "Rolls-Royce MT30". The turbine will provide the immense 109 MW of power for the 2 propellers, all the weaponry, radars, command sys, etc. of the new generation UK aircraft carriers of the Queen Elizabeth class. To this class belong HMS Queen Elizabeth (2017-commissioned) and HMS Prince of Wales (2019-commissioned), each of them with a total power consumption of 80 MW.

Gas-turbine cruise ship power system

The first large vessel to use a new gas-turbine cruise ship propulsion system was Celebrity Millennium . This system will be more frequently used in new cruise ship buildings . It's innovative and, besides new activities available, the economy of scale, marketing, represents an important element of ship design. System's advantages include:

- lower vibrations and noise level, better comfort, lower probability of failure;

- lower exploitation costs because of the easier maintenance;

- nocive emissions reduction, which is partially owed to gas oil instead of fuel (-90% oxide of sulfur, -80% oxide of azote).

- considerable gain of weight and volume, especially when with Azipod marine propulsion system (900 tons, 70 cabins added).

Gas turbines at this time are only interesting in the building of high-speed ships (warships, and especially aircraft carriers, or fast passenger vessels - Millennium max speed is 25kn), because of the better diesel output in lower speeds and higher price of gasoil instead of fuel for diesel engines.

Gas turbine cruise ship propulsion systems are able to avoid pre-heating systems needed for fuel in classic installations (risk of fire!), as they use gasoil, Celebrity's Millenium-class and RCI's Radiance-class use such turbine powerplants. The next photo shows Celebrity's Solstice-class ship propulsion (the 4 aft azipods, and the underwater hull shape).

LNG-powered cruise ships

In June 2015, Carnival Corporation announced the company's contract with Fincantieri to build four LNG-powered vessels with the industry's largest passenger capacity. This was part of the order with Meyer Werft and Fincantieri for a total of 9x units to be built in the period 2019-2022.

The four newbuilds became the industry's first LNG (Liquefied Natural Gas) powered vessels using LNG in their hybrid engines. The gas is stored in the ship and used to generate all needed power at sea. The engines are not exclusively LNG, but "dual fuel" (capable of burring both liquid marine fuel and natural gas). This design is for saving onboard space (reducing fuel storage space required).

LNG is natural gas, which consists of 90% methane and 10% ethane. When cooled to -160 C, it passes from gas to liquid, and its volume decreases over 600 times, making it very efficient for distribution. Long-distance LNG transportation is via dual-hull gas carriers. Short-distance LNG transportation is via trucks or smaller vessels (also barges) fitted with high-pressure tanks.

Gas fuel eliminates all the bad emissions - soot and sulfur oxides. In April 2016 MSC Cruises announced its contract with STX France for up to four LNG-powered ships with GT over 200,000 tons each. For comparison, the Oasis of the Seas is 225,000 GT tons. The new MSC ships have 5400 passengers capacity at double occupancy each. The first one is scheduled for delivery in 2022. Its power plant will be based on a new prototype engine.

Using LNG to power large cruise ships is a relatively new (2016) concept. Due to LNG tanks' large sizes, this fuel is used usually on smaller passenger shipping vessels ( ferries ) operating on short crossing itineraries. LNG bunkering facilities available in ports are very few. Compared to other fuels (including MGO / marine gas oil), LNG is purer (no unburned residues, fewer greenhouse gases), more efficient, stable and cheaper (reduces fuel costs). LNG technology also advances due to IMO's future maritime emissions regulations, especially in ports and while operating in environmentally sensitive destinations.

In comparison to pipeline gas, LNG is superior in quality - purer, with more methane and other energy content. Its chemical structure also has a stable composition that doesn't generate unburned residues, soot or any particulates. In addition, because the fuel is so clean, on LNG-powered ships maintenance intervals are doubled (over 25,000 hours / ~10140 days), as opposed to the standard MDO-powered 12,500 hours (520 days).

- All the world's major environmental organizations and the marine shipping industry joined for an explicit prohibition on the carriage of non-compliant fuels when the 0,5% sulfur cap takes effect in 2020.

- In January 2018, IMO announced that starting January 1, 2020, the marine fuels' max allowed sulfur content (outside Emission Control Areas) is reduced from the previous 3,5% to 0,5%. Unless marine vessels are using approved equivalent compliance methods, after Jan 2020 there is no reason for ships to use non-compliant diesel fuels.

- IMO's new sulfur cap's goal is to provide substantial health benefits by reducing marine fuels' sulfur content (SOx gases). At the same time, IMO's lowered cap significantly increases ships' operating costs.

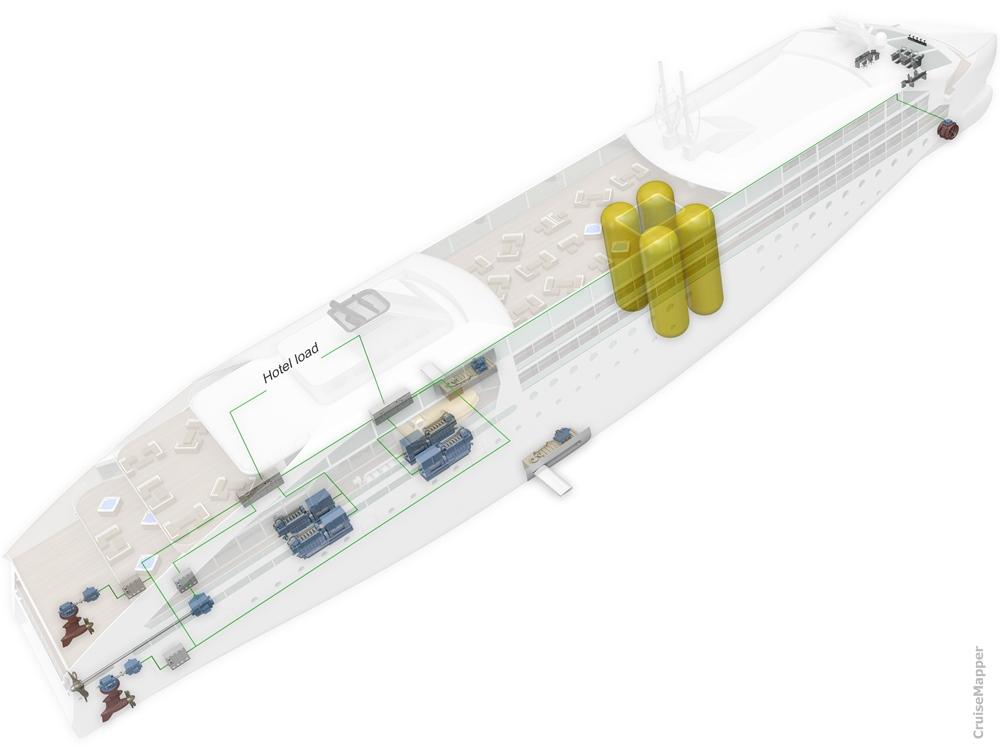

The LNG cruise ship concept was first introduced by Wartsila (Finnish manufacturing company) and is based on drive shaft propulsion instead of azipods. The LNG tanks' location is in the upper deck area (right below the funnels). The Rolls Royce concept is based on azipods.

AIDAprima (2016) is one of the world's most technologically advanced cruise vessels. The ship rides on a cushion of air, thus reducing frictions and fuel consumption, The new technology is called MALS ("Mitsubishi Air Lubrication System"), allowing the liner to glide on an air bubbles carpet.

The ship's 4 main engines are dual-fuel (heavy oil and LNG gas oil) thus reducing fuel consumption. The ship has an advanced filtering system that reduces stack emissions (greenhouse gases). The ship's propulsion features 1 pair of stabilizers and 2x ABB-pod drives (new XO-Pod series, power output per unit: is 3 MW). The total power output is 48 MW. AIDAprima is also the world's first-ever "LNG cruise ship" as it uses LNG fuel supply while berthed in ports.

For its LNG-bunkering operations in Florida (at homeports PortMiami and Port Canaveral ), CCL-Carnival partnered with Royal Dutch Shell plc as fuel supplier for the liners Mardi Gras (2021) and Celebration (2022).

AIDA's LNG-powered cruise ships

The AIDAprima ship's first successful test run for LNG supply was in Hamburg Germany on May 7, 2016. While berthed, the ship was successfully provided with LNG at all the itinerary's ports of call (Hamburg, Rotterdam, Le Havre, Southampton, Zeebrugge).

- The company's statistics show that the AIDA ship spends about 40% of its operating time in ports. Compared to using conventional marine diesel (0,1% sulfur content), by using LNG, the vessel's emissions were considerably reduced even further. Sulfur oxides and soot particles were prevented completely (while in port), nitrogen oxide emission was reduced by up to 80%, CO2 emissions were lowered by 20%.

- AIDA ships (produced by Shipyard Papenburg ) are 100% LNG-powered. AIDA invested in research and testing of LNG cruise ship technologies since 2015. In 2013, AIDA collaborated on LNG hybrid barges with Becker Marine Systems. The innovative and flexible solution is used on ships moored in Port Hamburg.

- Since May 30, 2015, AIDAsol is regularly supplied with low-emission LNG power at Hamburg's Hafencity Cruise Terminal.

- AIDA ships use just 3 liters (0,8 US gallons) of fuel on average per person on board for a 100 km (62 ml) trip. This was confirmed by an independent expert study in 2012. Following the implementation of new technologies and economical handling of resources, the company's statistics for 2016 (over 2012) showed reduced energy consumption (9% per person onboard), reduced water consumption (7,2% pp) and reduced CO2 emissions (7,7% pp).

Hurtigruten ships

In April 2018, the Norwegian cruise and ferry company Hurtigruten announced a USD 150 million fleet renovation project. Almost all vessels will be upgraded with new hybrid powerplants that combine LNG-engines and batteries.

For the project was contracted Rolls-Royce Marine, initially for 6 ships plus optional another 3. The program's completion was scheduled before January 1, 2021. The project also includes all vessels to be upgraded with shore power capabilities.

Dual-engine ferries (LNG-MDO)

The next scheme shows the dual-engine powerplant (Wartsila) and propulsion (Azipod) of the cruise ferry Tallink Megastar . This ship is the biggest "floating superstore" on the Baltic Sea, featuring a 2-deck retail shopping complex and the unique self-service option called "Q-shopping". The RoPax vessel uses LNG as prime fuel and MDO (marine diesel oil) as secondary fuel.

The ship is powered by a total of five Wartsila dual-fuel engines - three 12-cylinder (model 12V50DF, combined output 34,2 MW) plus two 6-cylinder (model 6L50DF, combined output 11,4 MW). Ferryboat's total power output is 45,6 MW. Its propulsion system includes two Wartsila fixed-pitch propellers with twin propeller shafts. Navigation systems are also Wartsila-made, including NACOS Platinum (integrated vessel control system).

The power generated by the main engines/powerplant produces electricity that is used from the propulsion motors, as well as all auxiliary systems and hotel functions. This innovative maritime technology allows the engines to be started and stopped depending on the onboard electricity demand, which additionally improves fuel efficiency.

Vessel's hull is ice-strengthened (class 1A). Rudders are from Becker Marine Systems. When compared to traditional marine engines, in gas mode, the ship's engines produce 1/4 less COx, 2/3 less NOx, zero SOx and no soot particles.

The onboard LNG system consists of 2 bunker stations, 2 horizontal LNG storage tanks by Linde (cryogenic, vacuum-insulated, stainless steel, total gas volume 600 m3), double-walled bunkering lines, pipelines (acid-proof stainless steel), special pipe fittings, gas distribution system, steam boilers. All the ship's electrical equipment is certified "explosion-proof". The LNG is stored at temperatures -160 Celsius (-256 Fahrenheit) and under pressure 4-6 bars.

ABB supplied the vessel's power and electric propulsion systems, as well as the Octopus (smart energy management system). While mechanical propulsion is optimized for a single-speed, electric propulsion is based on rotating speed control resulting in energy efficiency at all speeds. ABB's propulsion also improves passenger comfort as the ship runs much more quietly and smoothly. ABB's Octopus marine technology allows real-time monitoring of the vessel's energy (and fuel) consumption. Based on the collected data, the software suggests optimal performance recommendations.

Spain's first LNG-powered cruiseferry was Hypatia de Alejandria (2019) owned by BALEARIA .

Wind-assisted propulsion

On April 12, 2018, the VIKING LINE -owned ferry Viking Grace became the world's first-ever passenger ship equipped with a rotor sail utilizing wind power. This also made it the world's first hybrid vessel that uses both wind power and dual-fuel (diesel-gas) engines.

"Rotor Sail Solution" is an innovative technology developed by the company Norsepower Ltd (Finland) in 5 years. It reduces fuel consumption and also COx emissions up to 900 tons per year (depending on wind conditions).

The cylindrical rotor sail has a height of 24 m (79 ft) and a diameter of 4 m (13 ft). The technology is based on the "Flettner rotor" (patented by Anton Flettner in 1922) and uses the so-called "Magnus effect" - the spinning rotor (rotating cylinder) drags airflow faster around one side. This creates pressure/speed difference that moves it in the direction of the opposite (lower-pressure) side, creating a force at a right angle to the direction of the wind. This wind-assisted propulsion power drives the ship forward. Unlike traditional cloth sails, the rotor needs no furling (stowing), reefing (reducing sail's area) or line-tending. The rotor sail system is automated and shuts down when unfavorable changes in wind force or direction occur.

Added to the dual-fuel engines, the new technology makes Viking Grace one of the world's most environmentally-friendly passenger ships, operating with very low levels of emissions and noise. Norsepower's wind propulsion system was also installed on VIKING LINE's newest vessel (still unnamed) scheduled for delivery in 2020. The China-built ferryboat is equipped with two Norsepower-produced rotor sails, doubling its wind power potential.

Ship's powerplant includes 4x Wartsila engines (model 8L50DF, total power output 30,4 MW). Propulsion is diesel-electric (2x shafts with fixed-pitch propellers) and wind-assisted (with 1x rotor sail). Engines are dual-fuel (MDO-LNG). As gas tanks are larger than marine fuel tanks. they need 6 times more space. To save hull space, LNG tanks are located on an open deck. LNG tanks are two (type C / vacuum insulated), each with capacity 200 m3 and weight 140 tons (LNG weight 85 tons per tank).

MS Viking Grace is also the world's first ship with the energy recycling system "Ocean Marine" (developed by Climeon AB / Stockholm-based company). The system converts the excess heat (generated by engines and exhausts) into clean (emission-free) electricity with an annual capacity of 700,000 kWh. This electricity is primarily used on cabin decks (including for heating, hot water, lighting). The technology uses heat exchangers that evaporate a carrier fluid circulating in a closed system. This gas (at 2-bar pressure) drives a turbine, then a 100 kW generator produces electricity. After that, the gas is cooled (in a vacuum chamber) and liquefied. Cooling is rapid, as the cold fluid is sprayed out. Then Heat exchangers cool the carrier fluid to temperatures around 20 C / 68 F.

Cruise Ship Fuel Consumption

How much fuel do cruise ships use.

Cruise ship fuel consumption depends on the ship's size. For most vessels, the average consumption is 30-50 miles on a fuel gallon. This will be also determined by other factors using fuel. Ships' gas mileage varies depending on the type and size of ship, the number of passengers on board, and other factors. Larger ships need more fuel to move through the water.

RMS Queen Mary uses 6 tons of marine fuel per hour. Celebrity Eclipse gets 56 feet to the gallon. MS Zuiderdam - .0130 miles per gallon (0.34 tons fuel per mile). This may not seem very good mileage at first glance, however, cruise ships are moving at once thousands of people whereas a car is moving a few.

Nearly all contemporary cruise ships are powered by electricity (motors turn propellers). It powers the air conditioning systems, lights and all other appliances aboard the ship. Most vessels produce the electricity they need by using diesel engines. Some use gas turbine engines. Others use a combination of the two. HFO (heavy fuel oil) is used by diesel engines, while MGO (marine gas oil) is used by gas turbine engines. The MGO is similar to the jet airplanes' fuel.

Speed affects cruise ship fuel consumption because to go faster, vessels must increase the electricity flow to motors. Thus more engines are employed, and it, in turn, increases fuel consumption. For example, Queen Mary 2 consumes 237 tons MGO and 261 tons HFO a day when at full speed. After a certain point, the rate of return decreases from adding engines, because if a ship can manage 17 knots by two engines, it doesn't mean that four engines are going to produce 34 knots.

Cruise companies employ new technologies in order to reduce fuel consumption. Ship's hull, for example, can be applied by silicon coating in order to reduce friction as the ship goes through the water. Friction reduction on Celebrity Eclipse is 5%. Another experiment is LED lighting, using less energy and producing less heat (thus is reduced the demand for electricity and air conditioning). Celebrity Solstice-class vessels have solar panels' field over the AquaSpa pool area. This not only provides shade for the pool area but produced by solar panels electricity is used to decrease the electricity demand from the engines.

RMS Queen Mary 2 is equipped with exhaust gas economizers, using waste heat from engines to produce steam. Then steam is used to heat fuel and QM2 hotel accommodations, laundry, galleys. This reduces the energy amount that has to be produced by ship's engines. The Promas Lite system (mentioned above) generates cruise ship fuel savings in the range of 5-15% depending on the operation type and the actual performance of the ship's existing propeller.

How marine ships fuel consumption increases at higher speeds? Next infographic shows the speed-fuel consumption relation on container ships (their sizes are measured in TEU-containers/20 ft equivalent units), which are similar by speeds and even gross tonnage to cruise passenger ships.

Cruise Ship Pollution

Today cruising is one of the most popular vacations, but there are significant environmental downsides. Mega-ships burn the dirtiest fuel in the world, even if they are sitting in port. Asthma, cancer, respiratory illness, heart disease, are the results of burned in ports nasty bunker fuel.

Shore-to-Ship Power Supply

Those who support the cruise industry point out that cruising has never been more popular. However, more ships generate more pollution. A solution is to have docked vessels plug into the port's shore power grid. Most of the world's largest cruise ports have such dockside electrical hookups, reducing bad emissions by up to 95%.

Aka "cold ironing" and "shore-to-ship power", shore power capability allows berthed cruise ships to shut down their diesel engines (main and auxiliary) and plug into city's electrical grid, using locally-produced electricity for all shipboard equipment and services - including cooling, heating, lighting, emergency, etc. The technology greatly reduces exhaust emissions in seaports. Next video animation reviews this technology.

TUI Cruises Ships Environmental Report

TUI published the company's environmental impact report (first of its kind) including environmental objectives and TUI strategy for a 5-years period. TUI said it planned to issue reports every 2 years. According to it, in 2012 TUI reduced by 3.7% per nautical mile its fuel consumption, and expects further 5% reduction, reducing CO2 emission at the same time by 0.5 kg to 0.55 kg per traveler.

Energy efficiencies are the key to reduce fuel consumption, CO2, and other emissions, and contribute to climate protection. Mein Schiff 3, for example, is expected to feature special energy management systems that help to consume 30% less energy than comparable size ships. TUI is focused on reducing recycling and waste, too. In 2012, TUI reduced the waste amount to 10,7 L (per passenger day), which is 27,8% less (over 2011). In 2012, TUI used 54,463 tons of fuel, including 9,732 tons LSFO (low sulfur fuel oil), 40,880 tons HFO (heavy fuel oil) and 3,851 tons MDO (marine diesel oil). Fuel consumption was 0,367 tons per nautical mile.

All new TUI ships are built to the latest standards with environmentally-friendly marine technologies. These vessels, both as design (hull and superstructure) and implemented technologies, are highly energy-efficient. Each consumes 1/3 less energy compared to most cruise liners. The advanced exhaust cleaning system uses a catalytic and scrubber converter. This technology allows sulfur emissions to be reduced by 99%, and NOx emissions - by 75%.

All-electric passenger ships

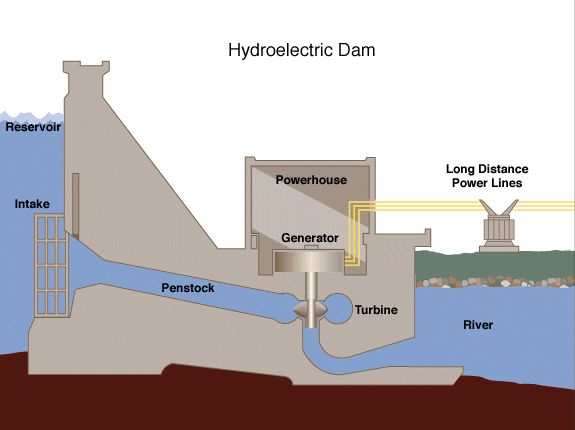

In May 2019, the US company "Maid of the Mist" ordered ABB two new all-electric vessels for the company's Niagara Falls tours. Both catamarans are 100% emission-free being powered by high-capacity batteries. Each ship is fitted with two battery packs (combined capacity 316 kWh / 563 HP output). The electricity is provided by 2 fully-independent power systems and split evenly between the 2 hulls.

Shoreside battery charging takes just 7 min (per ship). The powerplant is controlled by ABB's PEMS (Power and Energy Management System), which also optimizes the onboard energy use. Ships' batteries are charged using hydropower (water-generated electricity), which as of 2019 accounts for ~7% of the USA's total electricity production. In addition to the shoreside charging connection, ABB supplied the newbuilds with switchboards, motors, integrated control systems and ABB Ability's Marine Remote Diagnostic System (24-hour equipment monitoring and predictive maintenance).

Battery power is used during turnaround navigation in ports when the onboard diesel-electric generators are switched off. For ferry batteries (fabrication, delivery, and installation) is often contracted the Canadian company Corvus Energy (Richmond BC) - one of the world's largest manufacturers and suppliers of energy storage solutions (ESS) for the maritime industry. The company provides ESS to hybrid and all-electric ferries. As of 2019, Corvus Energy delivered its innovative product line "Orca ESS" to 200+ vessel conversion/upgrade projects, totaling 200+ MWh.

At the following tag-link can be found listed all CruiseMapper's news related to propulsion-power accidents .

This cruise vessel technology-related survey is integrated with our articles on passenger ships building and safety , and the statistical ones about registry/flag-states , cost to build , speed , passenger capacity . All ship links redirect to the vessel's "itinerary-schedule-current position" page.

Cruise Tips For Families & Single Cruisers

Things to Know Before You Cruise

Cruise Ship Propellers: Size, Speed, And Sustainability

As a cruise ship enthusiast and a lover of the open sea, I have always been fascinated by the sheer size and power of cruise ship propellers. These mammoth vessels require propellers that can withstand the harsh marine environment, while also providing the necessary thrust to navigate through the water.

In this article, we will delve into the world of cruise ship propellers, exploring their design, materials, and safety considerations, as well as the latest technological advancements that are improving their efficiency and sustainability.

From the traditional fixed-pitch propellers to the modern azipods, cruise ship propellers have come a long way in terms of design and functionality. These propellers must be strong enough to withstand the forces of the sea, while also being flexible enough to provide the necessary maneuverability for the ship.

In addition, the sustainability of cruise ship propellers is becoming increasingly important, as the industry strives to reduce its environmental impact and promote a more sustainable future.

Join me as we explore the fascinating world of cruise ship propellers, and discover how these powerful machines are shaping the future of ocean travel.

- Cruise ship propellers can vary in size and are made from an alloy of stainless steel and aluminium to withstand corrosion and degradation.

- Modern cruise ships use azipods, which have the propeller at the front of the pod and can spin 360 degrees to help with steering, and typically have three propellers for balance between fuel consumption, thrust, and manoeuvrability.

- The number of propellers a ship has determines its speed, fuel consumption, and ease of turning, and the biggest propellers belong to container ships, with the MSC Oscar having propellers that are approximately 35 feet in diameter.

- Changes are being made to cruise ship engines and fuel types to make ships more sustainable, and while the odds of falling overboard on a cruise ship are low, it’s not safe to swim over to a cruise ship in a dock due to sudden current shifts.

Propeller Design and Materials

I learned that cruise ship propellers are a crucial component of these mammoth vessels, designed to withstand the harsh conditions of the open sea. These propellers are made from an alloy of stainless steel and aluminium, chosen for their durability and corrosion resistance.

To ensure the safety of passengers, propeller design is carefully considered to minimize the risk of accidents. Propeller maintenance is also essential to ensure that the ship continues to operate smoothly and efficiently.

The manufacturing process involves precision engineering, with each propeller tailored to the specific needs of the ship. With modern advances in technology, propellers are becoming more efficient and eco-friendly, helping to reduce the environmental impact of these massive ships.

Overall, the design and construction of cruise ship propellers are critical to the safe and efficient operation of these vessels.

Propeller Function and Safety

Ensuring the proper maintenance of these underwater giants is crucial to keep them running smoothly and minimize the chances of any potential mishaps hitting the fan.

Cruise ship propellers are the workhorses of the ship, responsible for propelling these mammoth vessels through the water. They are designed to withstand the corrosive effects of saltwater and other forms of degradation. Any damage to the propeller can cause significant problems for the ship, including reduced speed, increased fuel consumption, and even accidents.

Propeller maintenance is an ongoing process that involves regular inspections, cleaning, and repairs. The blades must be checked for cracks, erosion, and other forms of damage. The propeller shaft must also be inspected for wear and tear. Any damage found must be repaired promptly to prevent further damage.

Propeller accidents can be catastrophic, causing damage to the ship and putting the lives of passengers and crew at risk. Proper maintenance is essential to prevent accidents and ensure that the ship operates safely and efficiently.

Modern Technology and Efficiency

Implementing new technology and more efficient systems has become a top priority for the maritime industry. Cruise ship companies are investing in modern technology to reduce their carbon footprint and improve their efficiency.

Here are some of the efficiency improvements and future developments in cruise ship propellers:

Electric propulsion systems – Some cruise ships are replacing their traditional diesel engines with electric propulsion systems. These systems have fewer moving parts and are more efficient than their diesel counterparts. They also produce fewer emissions, making them more environmentally friendly.

Advanced propeller designs – Cruise ship propellers are becoming more advanced, with designs that reduce drag and improve efficiency. These new designs use materials that are lighter and stronger than traditional stainless steel and aluminum alloys.

Azipod technology – Azipod technology, which allows the ship to turn in any direction without the use of a rudder, is becoming more popular in the cruise industry. These systems use less fuel and are more maneuverable than traditional propulsion systems.

Alternative fuels – Cruise ships are exploring alternative fuels such as LNG (liquefied natural gas) and hydrogen fuel cells. These fuels produce fewer emissions than traditional diesel and are more sustainable in the long run.

Efficiency improvements and future developments in cruise ship propellers are essential for the maritime industry to reduce its environmental impact and improve its efficiency. As technology continues to evolve, we can expect to see more advanced propulsion systems and designs in the future. The use of alternative fuels and electric propulsion systems will also become more prevalent, making cruise ships more sustainable and environmentally friendly.

Environmental Impact and Sustainability

Reducing the environmental impact of maritime transportation is crucial for the future of our planet. As the world becomes more aware of the impact of carbon emissions on our environment, the cruise industry is looking to alternative fuel sources to power their ships and reduce their carbon footprint.

One such fuel is liquefied natural gas (LNG), which has lower emissions than traditional fuels such as diesel. In fact, some new ships are being designed to run entirely on LNG, which will significantly reduce their carbon emissions.

In addition to alternative fuels, cruise companies are also investing in technology to reduce their environmental impact. One area of focus is the use of azipod propellers, which are more efficient than traditional propellers and require less power to operate. This means that ships using azipods can travel further and faster while using less fuel, resulting in fewer carbon emissions.

Overall, the cruise industry is working to find sustainable solutions to reduce its impact on the environment and protect the planet for future generations.

How often do cruise ship propellers need to be replaced?

The lifespan of cruise ship propellers varies depending on usage and maintenance frequency. Generally, they can last between 5-10 years before needing replacement. Regular inspections and repairs can extend their lifespan and ensure safe operation.

How do cruise ship propellers affect marine life?

Cruise ship propellers act as the beating heart of a ship, but their impact extends beyond. They disrupt the marine ecosystem, causing environmental damage. The underwater noise can harm marine life, affecting their communication and migration patterns.

Can cruise ship propellers be recycled?

Unfortunately, cruise ship propellers cannot be easily recycled due to their complex materials and design. This contributes to their environmental impact, but efforts are being made to improve sustainability through more efficient propeller technology.

How do propellers impact the noise level on a cruise ship?

As I stand on the deck of the cruise ship, I can’t help but notice the smoothness of the ride. The propeller design plays a crucial role in reducing vibrations and noise levels. Modern advances in technology have made it possible to create more efficient and quieter propellers.

Are there any alternative propulsion systems being developed for cruise ships?

I’ve been researching alternative solutions for cruise ship propulsion, and future prospects are looking promising. New technologies like fuel cells, wind power, and hybrid systems are being developed to reduce emissions and increase efficiency, offering a greener future for the industry.

- The Best VPN Services in 2024 (+Bonus Software)

- Square: The Best All-in-one Payment Processing Solution for Small Businesses

- Surfshark: Secure Online VPN Service & More

- Shopify: Start and Grow Your E-commerce Business Right Now

- DocHub: Easily Edit, Fill & Sign PDF Files On the Go

- How To Avoid Being Overcharged By An Airline For Travel Visa

- 4 Best Practices for Airport Wi-Fi Networks

- 5 Best Practices To Make Your Internet Faster

Propulsion of Cruise Liners and Other Ships – How These Floating Sea Mammoths Move

Welcome aboard, maritime enthusiasts! Ever gazed at a massive cruise liner cutting a majestic path through the ocean and wondered, “Just how does that behemoth keep moving?” You’re not alone. In this blog post, we dive into the fascinating world of ship propulsion – the force that keeps these sea leviathans afloat and moving. The importance of propulsion systems in the movement of cruise liners and other ships can’t be overstated. In this journey, we’ll navigate through the history of ship propulsion, swing by the various types of propulsion systems, and explore how they work. We’ll also take a look at the innovating strides in modern ship propulsion, and discuss the environmental considerations that are steering the future of this technology. Strap in, and let’s set sail on this enlightening voyage!

Propulsion, in the simplest terms, refers to the action or process of pushing or driving an object forward. In the context of ships and cruise liners, propulsion is the mechanism that enables these massive structures to move across bodies of water. It involves harnessing various forms of energy to create a force that propels the ship forward, overcoming factors such as water resistance and ship weight. Thus, propulsion is a vital element in maritime travel, acting as the ‘engine’ that powers the movement of ships.

The importance of propulsion in cruise liners and other ships cannot be overstated. Primarily, it enables these enormous structures to navigate across vast oceans, carrying passengers or cargo from one point to another. Without it, ships would be static objects, incapable of serving their primary functions. But it’s not just about movement, propulsion systems also play a crucial role in ship maneuverability. They allow ships to adjust their course, avoid obstacles, dock, and navigate through narrow passageways. Moreover, the type of propulsion system can also significantly impact a ship’s fuel efficiency, operational costs, and environmental footprint, making it a critical factor in the overall performance and sustainability of maritime operations.

Ships have been in use as a means of transport since early times. Ships are believed to have originated from rafts. Earlier ships used oars and were moved using sheer manpower. Later they were powered by wind with the help of sails. Then steam, diesel, and now even nuclear power are being used. Ships have undergone tremendous change over the years. The basic structure and parts of a modern cruise liner are shown in the figure.

Various parts of a modern ship. 1. Funnel 2. Stern 3. Propeller and rudder 4. Portside (right side is starboard side) 5. Anchor 6. Bulbous bow 7. Bow 8. Deck 9. Superstructure

Motions of ships require heavy power generation and an effective propulsion system. Without suitable means of propulsion, ships will be just floating iron mountains and nothing more. What causes a ship to move through the water? Propellers have this responsibility.

The propulsion of ships normally occurs with the assistance of a propeller. It has three or four (or sometimes even more in the case of propellers aimed at working under low noise conditions) blades. These blades are twisted and poking out at angles from a central hub (a rounded region on which the blades are attached). The hub is connected to a shaft which is connected to the ship’s engine. Usually, there will be two propellers and sometimes even more, and they are provided at the rear end of the ship. Propellers of ships and cruise liners are comparatively very large in size and require heavy torque for rotation.

How does a Propeller Work?

Sir Isaac Newton stated in one of his works “Actio est reactio”. This sounds very familiar. This is Newton’s third law. Propellers work based on Newton’s third law which states that for every action there is an equal and opposite reaction. When the propeller is made to rotate, it draws water from the front of the ship and accelerates it towards the rear or backside of the ship. Because of the momentum imparted by the propeller to water, it experiences an equal backward momentum. In other words, water exerts a force on the propeller in the opposite direction. This force is called thrust. The thrust developed on the propellers is transferred to the ship’s structure through the main shaft which ends in a thrust bearing. In this way, propellers generate sufficient thrust to move the ship forward. Explanation of propulsive force generated by a propeller is very complex and is beyond the scope of our present topic. Earlier ships used rudders to help them steer. A rudder is basically a large flap provided at the back of the propeller. For steering, the rudder is inclined at an angle which changes the direction of expelled water. This results in a change in the direction of reactive force (sideways). This in turn helps the ship to turn.

Engine: The Heart of the Ship

Many engines were developed over the course of time to make ships faster and more efficient. Out of the many proposed theories steam engines and later diesel engines were put into practice. Turbines are also used sometimes in combination to generate sufficient power (also electricity for the ship). The workings of steam and diesel engines are explained below.

1. Triple-expansion steam engines

Earlier steam engines were of single expansion type (steam is made to expand only in one stage) but they were later modified to triple expansion types. Triple-expansion steam engines were the most common and advanced engines used in the early days. The chemical energy of coal is converted to thermal energy by burning coal to generate steam. This is done in very large boilers. Steam at high pressure from the boiler is supplied to the engine.

The engine basically consists of three cylinders. High-pressure steam

is supplied to the first cylinder. Steam expands pushing the piston down. The steam from the first high-pressure cylinder then goes to an intermediate cylinder where it again expands. The resulting low-pressure steam then goes to the last cylinder where it undergoes the final expansion. Steam is made to expand in three successive stages hence the name triple expansion engine. Triple expansion engines provided greater speed as well as better heat conversion (to mechanical energy). The pistons of the three cylinders are connected to the main propeller shaft and they work together to rotate the shaft as shown in the animation shown alongside.

ALSO CHECK OUT OUR OTHER ARTICLES

- Top 20 Engineering Websites