MOORING LINES

When the stakes are high, count on dyneema® sk78 fiber, made for: lng carriers, oil tankers, dry bulkers, container carriers, cruise ships, inland ships, dyneema® enables strength plus+, lighter than steel wire rope, the fatigue lifetime*, longer rope abrasion and creep lifetime*, choosing your next mooring rope know your facts.

Fatigue. Abrasion. Creep. Temperature.

Unmatched safety and reliability

Durability woven in, low weight, high efficiency, unmatched sustainability, want the same high performance with a lower carbon footprint, proven product performance, rope tension fatigue model, fairlead abrasions test, creep performance tool, rope temperature model, over 10 years, lines made with dyneema® fiber have exceeded our expectations, bringing clear benefits in lifetime performance, efficiency, and safety. we’re delighted to extend our relationship with our partner and to use mooring ropes made with dyneema® sk78 fiber on even more oil tankers., a history of excellence: meg4 meets dyneema® sk78 fiber, read our case studies, cosco mooring lines still going strong after 11,000 hours, dyneema® aids dangerous rescue of bulk carrier mv benita, solving an industry-wide mooring challenge with samson, preferred. trusted. certified..

Contact our sales team

Stronger together.

Where to buy

Mooring lines made with Dyneema® are available from our trusted sellers across the globe.

Design with Dyneema®

Read related articles, the ocimf and meg4, know the facts, authenticating mooring certificates, mooring and port safety.

888-596-7673

For All Your Cordage Needs - Yachts, Ships & More

- 3 Strand Nylon

- Double Braid Nylon

- 8-Strand Nylon

- Mega Braid 12 Strand

- Double Braid Polyester

- High Performance Line

- AmSteel® Blue 12 Strand

- Purple Plasma Rope

- Manila Rope

- Tylaska Snap Shackles

- Anchor Chain

- Dyneema Soft Shackles

- Mega Yachts

- Pleasure Marine

- Commercial Marine

- Military & Government

- Architectural & Decorative

- Industrial and Utility

- Choosing Dock Lines

- Rope Glossary

- Splicing Services

- Conversion Chart

- Company Brief

- Contact / Inquiries

Commercial Marine Rope

Commercial Ropes and Cordage

Rope inc. has been a commercial marine and cruise ship industry supplier for more than twenty years..

Rope Inc. offers customers an array of options for Towing and Mooring Lines in Polypropylene, Polyolefin copolymer, Nylon, and Polyester. Sizes range from 1” up to 4”.

Super Dan mooring ropes and Blue Steel mooring ropes come standard 220m length with 2m Chafe covered eyes in each end.

Rope Inc. is capable of delivering worldwide to almost any country or location.

Contact us today for a quote.

Trust and Confidence

Rope Inc 268 SW 33rd Street Fort Lauderdale, Florida 33315 ( map )

We’re Here To Help You 888-596-7673 +1 954-525-6575 +1 954-525-5887

Home • Terms of Service • Privacy Policy Copyright © 2020-2022. All Rights Reserved – Rope Works Inc .

Mooring a Ship

When in port the ship either anchors or moors to facilitate loading and discharging operations. Each of these operations requires skills and detailed knowledge of the capability of the ship and local conditions. A pilot may provide some of these but there are some ports where the master may be required to berth his ship with only a skeletal assistance from shore.

- Understand and demonstrate the use of berthing equipment, machinery and gear.

- Learn, understand and demonstrate the principles of mooring arrangements normally taken into account when a ship is alongside a jetty.

- Demonstrate the use of rope and chain stoppers.

- Demonstrate the use of heaving lines and gantlines.

- Learn, understand and demonstrate a mooring operation.

Principles of mooring a ship alongside a Jetty

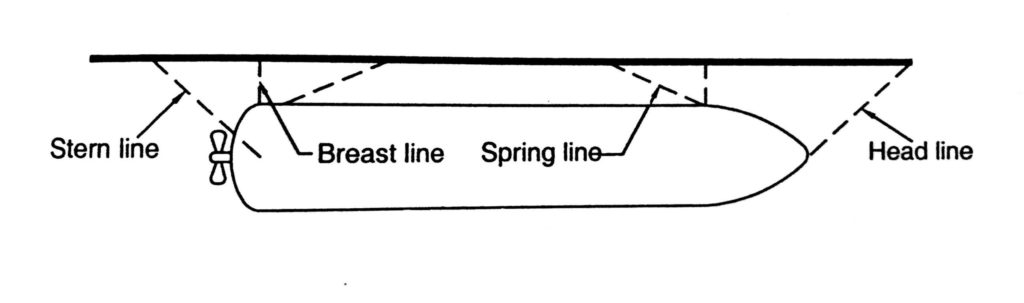

The figure shows a ship moored (made fast) alongside a wharf. The moorings in the figure are named as follows:

It will therefore be obvious that the head lines, stern lines and the fore and aft springs prevent the ship’s movement in the fore and aft direction. The breast ropes and to a certain extent the forward and stern lines prevent such movement in the athwartship direction.

After the ship is made fast or moored, the moorings need to be tended regularly to allow for: –

- Changes in the force and direction of the wind or current;

- Changes in the ship’s draft;

- Rise and fall of the tide.

“Remember the security of the ship alongside is as important as safe watchkeeping at sea. It needs personal attention of the deck watch throughout the time the ship is alongside. This demands good knowledge of the ship’s equipment and the principles of good mooring. The attention to mooring should be a planned activity.”

Jse of rope and chain stoppers

low to pass rope stoppers: .

Use of Rope or Chain Stoppers

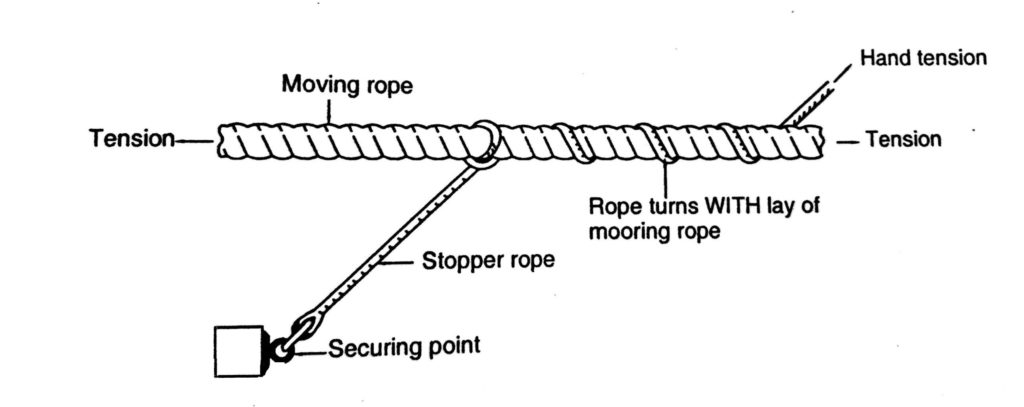

These are lengths of rope or chain secured to bitts to facilitate taking the mooring rope or wire from the drum and placing it on the bitts.

How to Pass Rope Stoppers

- First, secure one end of the stopper as near the bits as possible. This is done by reaving one end of the stopper through the eye at the other end, and slipping the bight thus formed over the bits.

- Now lay the stopper over the mooring hawser or wire and watch carefully. whether the stopper lies with the lay or against the lay. So, if the stopper with the lay, remove it and take it under the mooring hawser. This will now be against the lay

- It will be found that if the stopper is made fast to the right of the hawser when looking along the outward going part of the hawser, the stopper knot has to be started from top. Conversely, if the stopper is made fast to the left of the rope, the knot has to be started from below.

- Take a half hitch.

- Take another riding turn as for a rolling hitch, back up the stopper rope as shown in fig and take a number of turns round the mooring rope, with the lay. Now catch the end of stopper and pull it away from the bits at an angle of about 30° with the mooring hawser. Sometimes the riding turn is omitted, if the strain is not too much.

Chain Stopper

It consists of a length of about 7-mm diameter open link chain, about 1 .5 metres long. One end of this chain has a wide link, while at the other end is spliced (by chain splice) a length of about 1.5 metres of small rope (10-mm diameter). A chain stopper should never be used for vegetable or synthetic fibre ropes, as it will cut them.

How to Pass Chain Stopper

Take another half hitch about 45 cms away from the first half hitch in such a Way that if the two half hitches were close together they will form a cow hitch and not a Clove Hitch. Now back up the chain and take turns around the wire against the lay of the wire. When sufficient turns are taken, catch the stopper end and pull away from the bits at 30-degree angle with the wire.

West Country Stopper

West Country stopper is a synthetic fibre rope (other than nylon) of about 25-rnm diameter and five to six metres long. Both ends are whipped. It is used for stopping synthetic fibre hawsers. The stopper is folded in two equal halves and the bight put around the bits. The two parts of the stopper are crossed alternatively Over and under the hawser a number of times. Finally, the two ends of the stopper are pulled away from the bits.

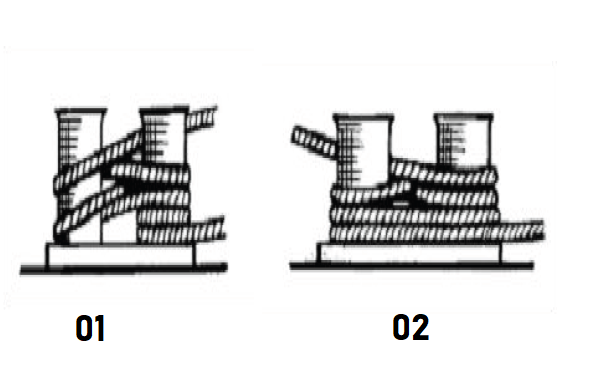

Securing Rope on Bitts

At least three ‘figures of eight’ turns should be taken. First figure of 8 turn should be taken round the bitts. The next two turns can be ordinary criss-cross turns. Wire ropes when made fast on bits should be lashed.

Use the following methods to turn the mooring ropes around the bitts for a safe arrangement:

a) For Large size bitts – take two round turns (but no more) around the leading post of the bitts before applying figure of eight, as illustrated in the below figure 01.

b) For Smaller circumference bitts – take turns around both posts before applying figure of eight, as illustrated in the below figure 02.

Throwing a heaving Line

A heaving line is a light thin rope, about 15 fathoms long. It may be a 6-mm or 8 mm, diameter vegetable fibre rope or a nylon rope. One end of it is weighted by making a monkey fist or a heaving line knot on it and the other end is just whipped. Do not insert any weight in side the monkeys’ fist as it may break somebody’s skull. Only oakum may be stuffed.

A heaving line is used to make contact with the wharf so that mooring hawsers may be passed ashore. To throw the heaving line, tie the whipped end on the rails or on your left wrist, and then coil all the line in your left hand, using small coils. Now transfer 1/3 of the coils including the weighted end in your right hand Swing the heaving line in your right hand like the lasso of the cowboy and at the same time pay off from the left hand. The swing should be at shoulder height and horizontal. Heaving lines can be thrown up to 25 meters distance. it is advantageous to wet line before throwing.

The efficiency of a heaving line thrower lies not only in sending it far but in the speed of recoiling the rope and re-throwing it, if it misses the first time.

It is a 16 or 20 mm diameter rope used for bringing on board a heavy hawser With some strain on it when a heaving line is not considered strong enough. If the hawser is under strain it may be able to pull the extra hawser on its own, provided the number of turns on the bits or the drum are not many remove a few turns until the hawser is able to slacken itself. A little manipulation of the remaining turns may be necessary. It may be borne in mind that while slacking from the bits is a comparatively easy operation; slacking from the warping drum presents difficulties, as after sometime the turns tend to get mixed up. It is, therefore, advisable to shift the hawser to bits if prolonged slackening is expected.

Aariya (Indian Crew)

This order means to slack away the rope or hawser.

Check the Rope:

This order is given when the hawser is being slacked away. On hearing this order take one more turn on the bits or on the drum and pull on the inner part of the hawser to check the hawser from running away. Let the hawser become tight but not too tight. Feed a little slack as soon as the hawser gets too tight.

Means that the hawser should neither be slacked nor hove up. Carry out this order by taking one more turn on the bits or drum. Of course, don’t break the hawser and if you think that the strain is too much and the hawser may part, inform the bridge and slack just a little.

At this order, make fast the hawser on the bits. If the hawser is on the drum, it shall be transferred to the bits.

This is done as follow: –

Pass a stopper on the hawser ends when ready, slack a little hawser from the drum or walk it back a little to shift the strain gently onto the stopper. When the stopper has taken the strain, quickly remove the hawser from the drum and make it fast on the bits, taking in all the slack. Unhitch the stopper.

It means remove all turns from bitts or drum.

It means that all lines should be cast off except the minimum necessary to keep the ship in position. The Master on pilot’s advice orders the minimum necessary. When the ships is to leave berth, stations are called and the crew take in all extra hawsers, so that when the order ” LET GO” is given, there are only one or more ropes to contend with. Generally this order is qualified by stating what lines are to be kept, e.g., “Single up to a line and back spring” or “Single up to a slip wire” etc.

At this order “off turns” and slack down the hawser, when the eye of the hawser is removed from the shore bollard heave it in quickly.

However, if the last hawser is to a buoy, do not “OFF TURNS” suddenly. The hawser will have a lot of strain on it. So slack away gradually at first until the hawser stops slackening itself. You will observe that as you slack away the buoy

Sending Away the Headline or Sternline

There are two ways of sending away a line:

a) By mooring boat: Lower your hawser upto about half a metre above the waterline. When the mooring boat gets hold of the end, follow instructions and slack away. However, if you are on the after station never slacks to much. Otherwise, the bight of the hawser will foul the propeller. when the mooring boat has secured the eye of the hawser on the shore bollard (or buoy ring), lead the hawser to the warping drum and pick up the slack.

” When the boat is picking up the stern lines, inform the bridge so that engine movements are not given.”

b By heaving line: If the jetty is not too far off, throw the heaving line and when the shore labour have got hold of the end of your heaving line, haul in the slack. Pull a bight of the heaving line in through the fair lead and tie it to the eye of the hawser. Now wait till the shore labour hauls on the heaving line, slack away on the hawser and on the heaving line until the shore labour gets hold of the hawser. They will then untie the heaving line and put the hawser eye over the bollards. Lead the hawser to the warping drum and pick up the slack.

“Havyes” (Havis) this term is a corruption of “Hoist” and means ‘Heave Away’.

Take three turns of the hawser round the warping drum and pull on the inner part of the hawser just behind the turns. If due to heavy strain the turns slip, take another turn on the drum.

Avast heaving: it means, “Stop heaving”

Surge: Sometimes, it is not convenient to stop the turning of the warping drum, even though it has become necessary to stop heaving the hawser. The hawser is then “Surged” i.e. the number of turns on the drum are reduced and the inner or hauling part of the hawser held still or raised slightly. This enables the hawser to slacken itself in jerks after every few centimetres of heaving and thus it remains stationary, neither heaving nor slacking.

Surging is not good for the hawser as it heats up the hawser due to friction. Synthetic fibre rope should never be surged. (Unless it is a “KEVLAR” rope)

Slack Away: The order “Slack Away means: “Pay out on the hawser so that a longer length is Outside the ship”. – moorings take in the slack. Once slack throw off the turns and slack down the hawser, keep it slacked down while the hawser is being unhitched from the buoy ring. Heave in quickly when the hawser is unhitched.

General Safety Precautions

Follow these very strictly.

- Never stand in a bight of a rope.

- Never stand with the legs on either side of a rope, which is being worked. This mistake is commonly made when passing stoppers.

- When a tug is pulling hard on a towrope, keep in a safe position to avoid being hurt by the whiplash if the towrope parts.

- Never look over the bows by standing over the fairleads. Your foot may be caught between the rope and roller.

- Never put the eye of a slip wire over the bits. Always make it fast by taking turns, so that the end can be easily cast off even if the slip wire is under strain. This principle is also to be followed whenever the tug’s rope is to be made fast on board, unless specifically instructed to put the eye on the bits.

- When a wire rope is to be used, take out the required length of wire and range a good length of wire on the deck. Never use a wire rope directly from the reel. Because if the wire rope fouls, the reel itself may be torn off from the deck. Similar precaution is necessary when passing a line to the tug.

- Always take precautions against the rope or wire taking charge and running out on its own, under its own weight or under the pull of a powered mooring boat. A turn on the bits or a half hitch of the stopper will keep the rope under control.

- Quite often, a back spring is led to a cargo winch for heaving with the aid of lead blocks. These blocks should have a proof load equal to the breaking strength of the wire rope and should be fixed on such positions as to provide correct leads.

- The winch, capstan or windlass should always be under the control of an experienced person. He should never leave the controls to attend to any other work

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

- Subscriptions

Grab a Seat at the Captain’s Table

Essential news coupled with the finest maritime content sourced from across the globe.

Join our crew and become one of the 106,878 members that receive our newsletter.

Four Factors To Consider When Selecting The Right Mooring Lines For Your Vessel

Share this article.

Safe and reliable mooring needs ropes to perform, often in adverse weather and changing port conditions. There are four silent saboteurs that degrade performance and safety margins: Fatigue, Abrasion, Creep, and extreme Temperatures. These are the FACTs (for short) that you need to know in order to select the right mooring lines for your vessels. Over the coming months we’re going to explore each one of these ‘ FACT s’ in detail, starting in this article with Fatigue.

Let’s deep dive into ‘fatigue’

A ship resting at a berth is in reality in constant motion. Gusts of wind, rising and falling tides, underwater currents, and surges from passing ships are all pulling moored ships in multiple directions simultaneously. Over time these motions impart fatigue damage to mooring lines. Every second the lines are moving from slack to taut, stressing the rope structure and the fibers they are made of. Rough weather or spring tides exacerbate the strains, and the mooring lines need to safely manage extraordinary loads, and relentless demands to bend and stretch.

Extreme events can suddenly reduce the safety margin on mooring systems. In real-world operations, time takes its toll, and if you’re operating in high temperature climates it can accelerate the onset of fatigue damage. From the minor strains of the daily tides to hurricane force winds, the fibers deep in the rope structure endure axial and bending stress and rub against each other. The question isn’t if fatigue will cause rope failure, it’s when. Which is why the challenge for mooring line manufacturers is to innovate more durable and reliable systems, starting with using a superior high-performance fiber.

Trusted performance and a long service lifetime with Dyneema ® SK78 fiber

Synthetic fibers have transformed mooring rope performance, making lines more durable, stronger, and lighter to handle. The king of synthetic high-performance fibers is Dyneema ® SK78. Dyneema ® SK78 has three times the fatigue life of generic HMPE, proven at both a fiber and rope level.

What’s the magic ingredient?

To better understand Dyneema ® SK78 fiber let’s study it on a molecular level. If you could view Dyneema ® SK78 fibers through a microscope you would notice not only a long, strong chain of atoms, but also anchors placed along the chain. These anchors stabilize the chain of atoms, giving the fibers a hidden reinforcement, a kind of superpower. When lesser fibers buckle, tear or fail, Dyneema ® SK78 fibers hold strong. Only Dyneema ® SK78 fiber is made from a tailor-made raw material that is selected with end-uses including mooring in mind.

Tested from the lab to the port

Lab and field testing has proven that Dyneema ® SK78 fiber delivers three times longer fatigue life compared to other alternatives.

But can the results from a lab translate to the reality of real-world applications? The feedback from the maritime industry is a resounding “YES!”. From epic container ships and tankers to cruise ships and tugboats, thousands of vessels over the last couple of decades have been equipped with mooring lines made with Dyneema ® SK78 fiber for safe and reliable mooring operations. Operators are experiencing the performance of their mooring lines in all conditions and their continuous feedback confirms that maintenance remains minimal and mooring line lifespans remain long.

Dive deeper into ‘fatigue’

Selecting the right material with the right rope design is essential when looking for more durable breast, head, spring, and stern mooring line systems. Dyneema ® SK78 fiber is engineered to deliver trusted strength, longer service life, and reliable performance. Check out the video below to dive deeper into fatigue. And to continue the conversation, contact the mooring experts at Dyneema ® from the link Connect to an expert (dsm.com)

Unlock Exclusive Insights Today!

Join the gCaptain Club for curated content, insider opinions, and vibrant community discussions.

Be the First to Know

Join the 106,878 members that receive our newsletter.

Have a news tip? Let us know.

Stay Ahead with Our Weekly ‘Dispatch’ Email

Dive into a sea of curated content with our weekly ‘Dispatch’ email. Your personal maritime briefing awaits!

Related Articles

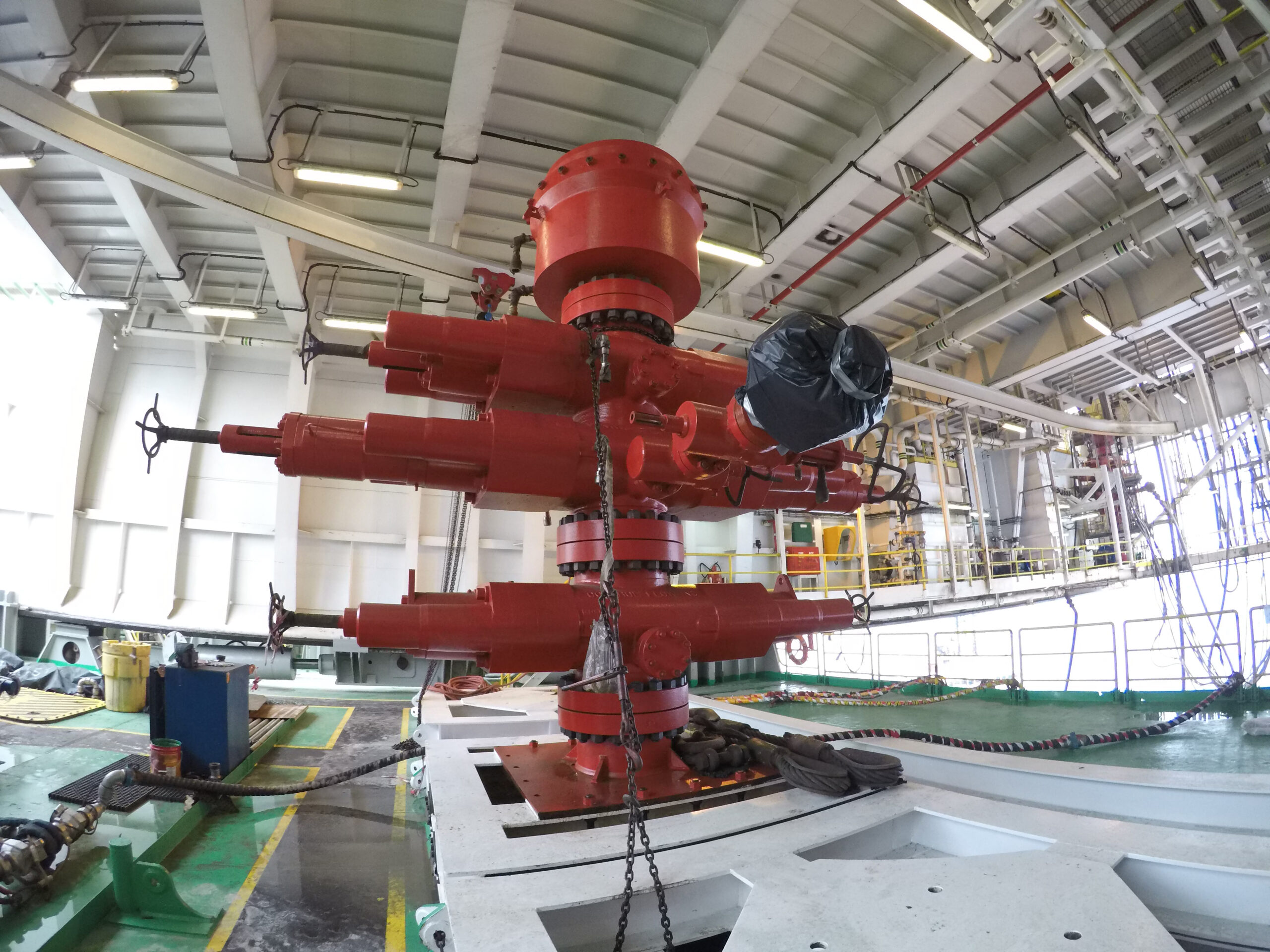

The Critical Role of Blowout Preventers in Offshore Operations

April 20 marks the anniversary of the Deepwater Horizon explosion and spill, a disaster that claimed 11 lives and caused the worst accidental oil spill in history. Caused by numerous oversights and decisions...

EverClean Improves Performance and Reduces Fuel Costs up to 20%

Greensea IQ’s EverClean proactive hull cleaning service represents a revolutionary shift in biofouling prevention, leveraging robotics to replace traditional, costly, and inefficient cleaning methods. By employing regular, in-water cleaning, EverClean...

Technology Helping Prevent Whale Strikes

Whales are magnificent, intelligent mammals whose life span can be as long as a human’s. However, their lives can be cut short. As many as 80 whales are estimated to die each...

Why Join the gCaptain Club?

Access exclusive insights, engage in vibrant discussions, and gain perspectives from our CEO.

OUT AT SEA?

We’ve got you covered with trusted maritime and offshore news from wherever you are.

JOIN OUR CREW

Maritime and offshore news trusted by our 106,878 members delivered daily straight to your inbox.

Your Gateway to the Maritime World!

Join our crew.

Privacy Overview

- +45 76225015

- Dynamica Ropes

- Mooring & Towing ropes

Dynamica Mooring & Towing ropes for ships

Abrasion - & uv resistant ropes.

Lighter, safer, strong mooring and towing ropes used for LNG, VLCC, tugboats, luxury yachts, bulk carriers etc.

- Technical information

- Strong as steel

- 10 times lighter than steel

- 3-4 % elongation

Applications

- Mooring & Towing rope

- Construction

- BS & weight

- Cover & protection

Why choose Dynamica Towing & Mooring ropes?

Dynamica Mooring ropes are the preferred choice for all types of vessels; biggest containers, bulk carriers, navy, tankers, LNG vessels, ferries, barges, tug boats, fishing vessels to luxury yachts and smaller boats.

Recommended for split drums winch applications. Not recommended for use on H-bits, capstans cleats.

Dynamica Towing ropes are the preferred choice for ships, tugboats and other vessels that performe towing and tugging operations.

Dynamica Mooring & Towing ropes are made with HMPE/Dyneema ® making them lighter, safer and strong; combined with their excellent abrasion - and UV resistance, the ropes are ideal for many different mooring and towing operations.

By choosing Dynamica Mooring & Towing ropes you gain:

Safe worksites

Easy handling

Floats in water (depending on construction)

Less crew and heavy equipment for handling required

Resistant to most chemicals

No rust, long lifetime in the maritime environment

No need for grease/lubrication

High tension and bending fatigue resistance

Towing and Mooring rope construction

Dynamica Mooring & Towing ropes are manufactured with HMPE/Dyneema ® in a 12-strand braided construction. Besides this, your ropes can be constructed in many different ways e.g. with a braided or woven cover made of either of heavy duty polyester or Dyneema ® . Both covers can get a final treatment with a Double Shield Coationg (DSC) which prevents abrasion, penetration of sand/mud particles and UV.

If used on high seas or with strong winds, it is recommended by OCIMF that the rope is fitted with nylon, polyester or mixed rope stretchers in order to absorb the shock loads.

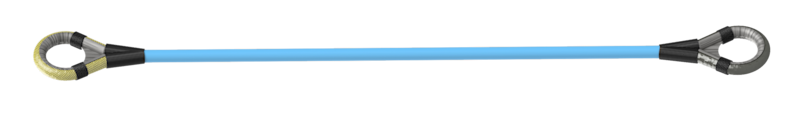

Our standard construction is a pennant with eyes with or without braided cover.

Thimble & masterlinks

Apart from the standard construction, Dynamica Mooring & Towing ropes can also be manufactured with customised solutions such as thimbles and masterlinks.

What is the breaking strength & weight of Dynamica Mooring & Towing ropes?

Dynamica Mooring & Towing ropes are as strong as steel while being up to 10 times lighter.

Interested in a specific diameter, breaking strength and weight? Request the information through the solution request!

What is the elongation of Dynamica mooring & towing ropes?

Dynamica Mooring & Towing ropes has elongation of only 3-4 %, which is similar to steel wire. For towing operations, this ensures more even tows.

The mooring and towing ropes are comfortable to handle for crew due to the stiff construction.

Eventhough we heat-stretch the mooring & towing ropes, you will experience elongation when taking the ropes in to use due to constructional elongation. After some operations, the rope will become more length stable than their steel wire counterparts. In case of breakage, the ropes' low mass and elongation results in the energy being distributed along the ropes’ entire length in a linear fashion with a relatively low recoil. Whereas, steel wire is known for lashing out endangering people and equipment.

Avoid rotating the rope during spooling as the rope will lose its strength and disturbe its construction, causing risk of failure.

When not in use, store the rope covered and away from sunlight to maintain as much strength as possible.

Use a good weather resistant coating to protect the rope from UV degradation.

How to cover Dynamica Towing & Mooring ropes?

Want longer service life? Protect your rope with a cover!

For Dynamica Mooring & Towing ropes, we recommend protecting your rope with either a braided polyester - or Dyneema ® cover.

The covers can be applied as follows

In the soft eyes

In the soft eyes and over the splice

In the soft eyes, over the splice in an agreed distance towards the middle of the rope

On the entire length

We always recommend covering the eyes and working ends, as these often are in contact with uncontrolled areas of service vessels or port facilities, that the crew have no control over.

Braided polyester cover

The braided polyester cover protects the rope against abrasion. It makes the rope non-floating, which is an advantage for some operations. On request, the cover can be treated with DSC.

Read more about braided polyester covers

Dynamica PRO cover

Dynamica PRO is a braided Dyneema ® cover which provides additional protection of the main rope. On request, the cover can be treated with DSC.

Read more about Dynamica PRO covers

What to look for while inspecting Dynamica Mooring & Towing ropes?

Regular inspections ensure a long service life and keep the total cost of ownership down.

Inspect the mooring and towing rope before every operation looking for the following signs:

Rope construction damage

Cover damage

Spooling damage

Splice or eye damage

Inconsistent diameter

Let’s talk about what you need!

Featured Products

HOW WELL DO YOU KNOW YOUR SYSTEM?

Mooring line recoil and associated crew safety are hot topics in the mooring industry today. Safety is a topic we are passionate about and have been working toward clarifying misconceptions related to safety and mooring line recoil. Not all ropes marketed as reducing recoil perform the same - it's important to understand the differences in products available in the marketplace.

DELIVERING CONFIDENCE TO MOORING OPERATORS

With over 10,000 lines in service, our experience in high-performance synthetic rope solutions for vessel mooring is unmatched, giving you the confidence to rise to any challenge your job presents.

The right rope for the right application

Mooring has significant operational demands, which is why our synthetic rope solutions not only equal the strength and durability of steel wire, they also allow for fewer crew members, shorter mooring operations, and safer, easier handling.

For more information on line selection watch our video on Mooring Line Durability Considerations .

Exposed terminal moorings

General working line, mooring stopper, mooring tails, primary mooring line, recoil safety, secondary mooring lines / h-bitt / capstan mooring / soft lines, ship to buoy mooring system, soft shackle, tow recovery, resources for mooring.

Consider Samson your partner in the field and on the water. In addition to our new integrated technology and service solution, Icaria™, we also provide a number of valuable resources to help ensure your operation’s success.

"K" Line UK

The 2016 expansion of the Panama Canal locks shortens the passage from the Atlantic to the Pacific Ocean by 9,000 miles for vessels that exceed the size limits of the old locks. This is a welcome alternative to “going ‘round the horn” through the Straits of Magellan, or cartage operations from coast to coast. Read more

Know What You Need?

- Rigging/Sails

6 Common Mooring Methods Used For Ships

Each vessel has been designed with mooring arrangements such that ropes and wires of recommended strength can help it moor safely alongside a berth, floating platform, buoy or jetty. Fundamentally a vessel has to be positioned alongside a jetty or a berth, between mooring buoys, to a mooring buoy, to another ship or barge and then made fast using her own anchors, mooring lines or shorelines.

Some very common methods of mooring are Mediterranean mooring, Baltic mooring, Running mooring, Standing mooring, Spider mooring buoys, Single-point or single buoy mooring, Conventional or multi buoy mooring, Ship to Ship Mooring

While Moored alongside a fixed or floating jetty or a sea berth there are various forces acting on the vessel such as wind, current, tide, wave action, swell, surging induced due to passing ships and trim of the vessel.

The spring, breast and head lines prevent the vessel’s movement against the action of these forces. The directional effect of these need not be unidirectional. It can be multi-directional or at various angles to the vessel .

The resultant direction of these forces often changes with changes in direction of onshore/offshore winds or tidal streams, currents upriver and down streams. Thus a combination of breast ropes, head ropes and spring ropes is the best method to counter these forces and keep the vessel safely alongside.

Often mixed moorings are observed as some terminals based on local conditions and experiences require vessels to use more lines than they are designed for. Thus the method in which wires in conjunction with soft ropes with different SWL and construction are used as well is termed Mixed mooring .

The simplified resultant of these forces would tend to move a vessel in the transverse or longitudinal direction with respect to the jetty. Thus spring lines prevent the longitudinal motion and the breast lines check the transverse motion.

It is always preferred to avoid mixed moorings due to variable loads and elasticity of various kinds of ropes and wires which lead to different strains or weights on the lines. This can result in excessive loads on some lines than others and eventually part them putting the vessel in danger. However, for safety reasons or in a desperate situation shipmasters or pilots may have to resort to mixed moorings.

Vessels sometimes also use the seaward anchor in conjunction with mooring lines to haul the vessel out of the jetty while casting off or while making fast the vessel alongside use the seaward anchor to assist the control of the rate of lateral movement towards the berth. This manoeuvre can be carried out with or without the assistance of tugs.

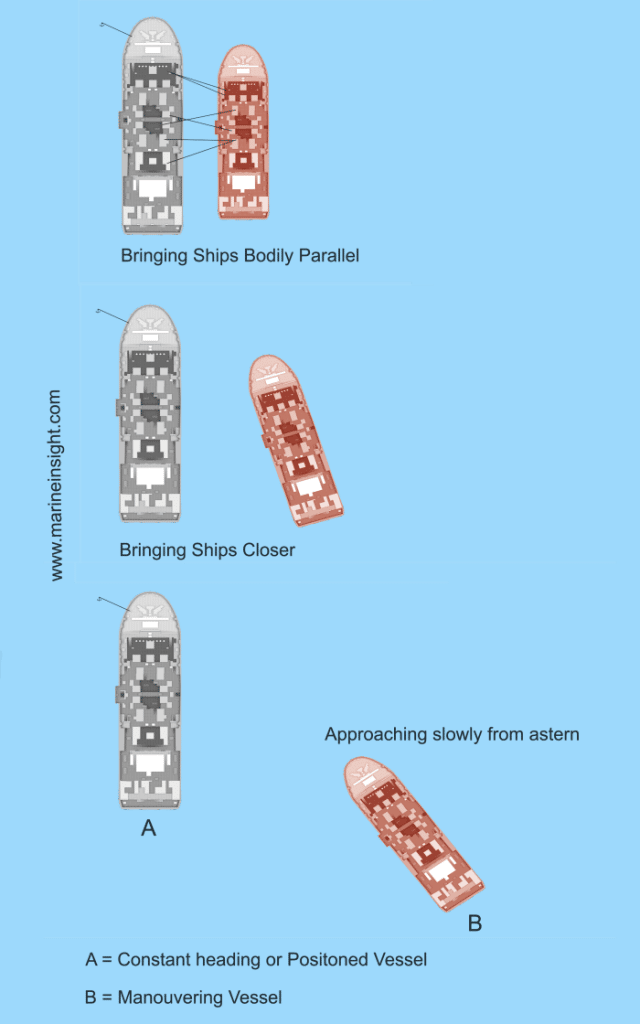

Ship to Ship transfer operation involves mooring alongside two different or same sized ships for cargo transfer. During this operation, either one of the ships is at anchor or both are underway.

The mooring arrangement depends on the size of the ships. A vessel either at anchor or stopped and maintaining a constant heading is approached by the manoeuvring ship at an angle of approach as smaller as practicable. The region of approach is usually abaft the beam of the constant heading ship.

During the approach as the manoeuvring ship comes closer, it steers a course parallel to the heading or course of the other ship and reduces the horizontal distance between ships to less than 100 metres. Once this state is achieved the manoeuvring ship uses engine and rudder movements and reduces this distance further until the fenders touch each other.

The two ships thus then make parallel contact and the lines are passed respectively as per the mooring plan. As a common practice during the approach, the wind and sea are preferred to be from ahead or at very small angles to the bow.

Single buoy or single point mooring: Often larger ships that cannot approach ports and terminals are berthed outside the port limits or in sheltered anchorages and the cargo transfer carried out with the help of Single-point or single buoy moorings.

The basic principle of the buoy is to keep the position of the vessel with respect to the buoy steady and at the same time allowing vessels to swing to wind and sea..

Often a tug is provided at the aft to keep the ship at a fixed angle and distance from the buoy. The buoy is fixed by positioning it in the centre of four anchors connected to it. The ship is made fast to the buoy with the help of a single chain or two which is secured onboard to the bow stopper.

In general, while approaching Single point or single buoy moorings weather is a major criteria in determining whether to berth the vessel or not. Calm seas with low swell and wind force below 15kts are considered favourable to make an approach. Presence of strong tidal current limits the interval for berthing and unberthing.

The headway approach has to be slow often less than while at the same time approaching at a smaller angle to the buoy and then gradually hauling in the buoy messenger rope and pulling the vessel slowly towards the buoy using engine kicks at short intervals to control and maintain headway along with mooring winches to haul in the vessel when she nears about 150-200 meters from the buoy.

For unberthing the chain is released from the bow stopper and a short kick on the engines going astern swings the bow to starboard for right-handed propellers thus clearing the vessel of the buoy. Tug’s assistance can also be sued to pull the vessel astern and clear it of the buoy. Know more about single point mooring here.

Conventional buoy or multi buoy mooring: In this method, the bow of the ship is secured using both her anchors whereas the stern is secured to buoy around it. In the approach firstly vessel approaches the final berthing position from forward at an angle of 90 degrees to her final direction of berthing.

The starboard anchor is then let go first at a pre-decided spot while the ship is making headway. The required amount of cable is paid and the astern propulsion too operated simultaneously to stop the vessel. Once the vessel is stopped in the water port anchor is let go and thus vessel positions her stern along the centerline bifurcating the buoys.

For aligning the vessel along this centerline port cable is paid out and starboard cable heaved in with astern propulsion. The helm and engines are to be carefully used during this manoeuvre to ensure the stern is swinging clear of any of the buoys.

During unberthing, the anchor cables are heaved in to move the vessel forward and the weight is taken on windward lines while casting off other lines to prevent swinging of the stern into the other buoys. This manoeuvre requires skill and efficient operation of the ship’s crew as well as of the mooring equipment as often weight of the lines can be immense.

Read on baltic mooring here.

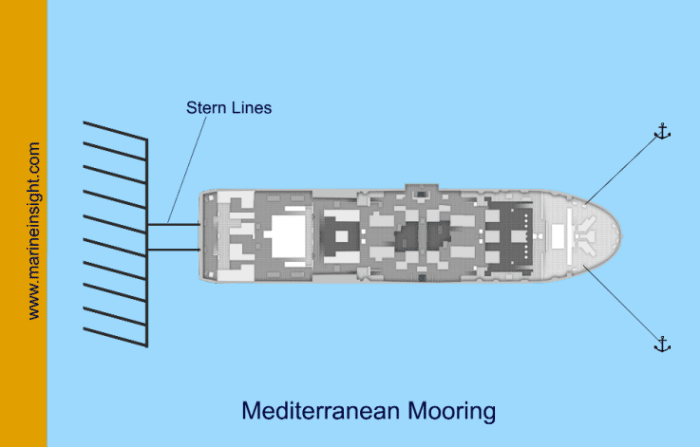

Mediterranean mooring: For this type of mooring, a pre-calculated position is determined and approached using engine movements. The bow initially is made to cant towards the berth and the starboard anchor is let go in that position.

After this, the engines are run astern and the port anchor is let go at the designated spot. The vessel falls astern and swings to starboard. Thus vessel is held by both the anchors as it approaches the quay. Stern lines are then passed. Moorings are kept tight by using the anchor cables.

The positioning of the vessel is such that mooring is completed with around four shackles on each anchor. Often tide is used to control the drift of the vessel towards the quay while positioning it by heaving or paying out on one of the anchors. Read more on mediterranean mooring here.

Running Mooring: This manoeuvre takes a relatively short duration compared to the Mediterranean mooring and offers more control of the vessel. The vessel’s starboard anchor is let go at a position approximately four to five shackles from the final position of the bow and around 9 shackles paid out while moving ahead on engines.

Then as she falls astern with the tide the port anchor is let go and the starboard anchor is heaved onto five shackles. This method restricts the swinging room and reduces the load on the windlass.

Standing Mooring: This is practised during crosswinds. As the vessel is stopped the port anchor is let go and with the tide around 9 shackles are paid out. The starboard anchor is let go and simultaneously port anchor heaved on.

Thus the port anchor is kept on 4 shackles being generally the flood anchor and starboard on five as it is the ebb anchor. This vessel takes longer duration and provides less control over the vessel. The load on the windlass is more as compared to running moor.

Over to you..

Do you know any other important mooring methods that can be added to this list?

Let’s know in the comments below.

About Author

Abhishek Bhanawat is a chief officer who has worked on various types of tankers. He specializes in Crude Oil and Product Tankers. He is highly passionate about his work and loves to sail.

Read More Articles By This Author >

Disclaimer : The information contained in this website is for general information purposes only. While we endeavour to keep the information up to date and correct, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability or availability with respect to the website or the information, products, services, or related graphics contained on the website for any purpose. Any reliance you place on such information is therefore strictly at your own risk.

In no event will we be liable for any loss or damage including without limitation, indirect or consequential loss or damage, or any loss or damage whatsoever arising from loss of data or profits arising out of, or in connection with, the use of this website.

Do you have info to share with us ? Suggest a correction

Related Articles

A Comprehensive Guide to Marine Sextant – Principles, Usage, and Maintenance

An Introduction to Fluxgate Compass

Important Points Officer on Watch (OOW) Must Consider While Handling Ship’s Radar

Daily Maritime News, Straight To Your Inbox

Sign Up To Get Daily Newsletters

Join over 60k+ people who read our daily newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

BE THE FIRST TO COMMENT

Wow, I never realized there were so many methods of mooring. I’m not much of a boater but have been tagging along with my uncle on his boat. He taught me about ship to ship mooring, but not these other ones. I like how you pointed out that a combination of breast, head, and spring ropes are best.

The mooring methods is very much and each mooring is unical. Usually we undestand standards methods for moorig, but in realy it is need to make some standards mooring methids. It is very important in mooring manouvering good comunication between all mooring members – master’s – pilot’s – ch. mate – mooring officers, sailors, tug’s masters, berth sailors. I’m tace in opinion not only tehnical comunication – loud speacers or portable VHF or spcial two way radio stations, but good communication between peoples.

I didn’t know there are so many mooring methods before reading your article that is very informative and impressive for me. These are standard mooring ways, for different mooring conditions, there will be specific mooring ways to suit the special environment requirements; during the mooring operations, safety should come first.

Is that in CBM anchor is used??? I have read elsewhere only messnger line helps to transfer the ships mooring to the different buoy around the ship and hepls the ship stay at a place doesnt allow to move like SPM. Here you have talked about use of anchor.can you provide any link or can you make video tutorial for all types of mooring system.thank you

Very nice irticle. I am a teacher for seaman. I want to use some part of your material in a handout to be given to candidates during training free of cost. Request your permission for it

@Capt. Devendra: You can use our articles by giving due credit to – https://www.marineinsight.com For free ebooks, we need an official email from the institute.

How do you moor a ship in areas of drastic tide movements?

About buoy mooring. How can we do mooring buoys with 3 meters of diameter? The buoy are made by plastic and it has got long tail and ballast.

Leave a Reply

Your email address will not be published. Required fields are marked *

Subscribe to Marine Insight Daily Newsletter

" * " indicates required fields

Marine Engineering

Marine Engine Air Compressor Marine Boiler Oily Water Separator Marine Electrical Ship Generator Ship Stabilizer

Nautical Science

Mooring Bridge Watchkeeping Ship Manoeuvring Nautical Charts Anchoring Nautical Equipment Shipboard Guidelines

Explore

Free Maritime eBooks Premium Maritime eBooks Marine Safety Financial Planning Marine Careers Maritime Law Ship Dry Dock

Shipping News Maritime Reports Videos Maritime Piracy Offshore Safety Of Life At Sea (SOLAS) MARPOL

WAIT! Did You Download 13 FREE Maritime eBooks?

Sign-up and download instantly!

We respect your privacy and take protecting it very seriously. No spam!

WAIT! Did You Download 12 FREE Maritime eBooks?

- Ask a Cruise Question

Technical Question: How to they get the ropes from the ship to the pier when docking?

By ahecht , August 21, 2012 in Ask a Cruise Question

Recommended Posts

Okay, so this is probably more of a "large boats" question then a cruise-specific question, but I figured that plenty of people here have watched ships dock. When the ships are docking, they usually come up along-side the pier using thrusters/azipods, and then are guided the rest of the way in using the ropes. My question is: how to they get the ropes from the ship to the dock?

In the following video, it looks like the ropes are just dropped in the water and then pulled up on the pier.

Are they actually using the wake from the azipods to push the ropes, were the ends of the rope connected to a thinner rope that can't be seen on the video, or is there some other method? Does anyone have better videos of this process?

Of course, none of this has ANY impact on my upcoming first cruise, but as an engineer, I'm curious. Maneuvering a large boat the size of a city block into a tiny concrete wharf is an amazing feat.

Link to comment

Share on other sites.

Yes they have thinner ropes or guidelines that are either tossed to waiting shoremen or are handled by deckhands in small motor boats to hoist the larger lines to the dock. I have even seen them "shoot" the guideline across with what looks like a type of airgun. Fascinating.

We watched them dock the Radiance in Hobart. They threw the smaller rope coil, which was attached to the heavier rope/cable, to the men on the dock, who then pulled the heavier rope up.

Fun to watch, not exactly high-tech!

They shoot the messenger line to the shore it usually has a weight on the end so the shore crew have something to grab

You can see it in the picture above

If your kids want to know, just tell them trained fish pull the ropes across to the guys waiting on the dock.:D:D

OneStrangeGuy

That weight on the end of the thrown line is called a "Heavie' (I might have spelled it wrong) and the line itself is called a 'Heavie line'.

Or sometimes the smaller rope is tied at the end in a complicated knot called a monkey's paw. It makes it look like a ball on the end, so it can be thrown.

On one line, I think it was Hurtigruten though I'm not 100% sure, they sometimes used shore-based boats to carry the rope ashore. Possibly because they're docking 6 or 7 times a day, they didn't want the main ropes to get wet.

Thanks for all the replies! Fascinating!

that's heaving line

A heaving line is a lightweight line which is used on board ship to establish a connection with people in another ship, people on the shore, or shipmates who have gone overboard. These lightweight ropes are typically weighted at one end, classically with a monkey's fist knot, and they are very easy to throw across long distances. Once a heaving line has been tossed, one end of the line can be attached to a heavier rope or object.

The advantage to a heaving line is that it is very easy to throw, and less dangerous for someone on the other end of the line. For example, when a ship docks, it is attached to the dock with heavy hawsers which keep it from moving. These hawsers could be extremely dangerous if they were just hurled from the ship to workers on the docks; instead, a heaving line is thrown and caught by a dock workers, and then a hawser is attached on the ship, allowing the dock worker to easily pull the hawser to the dock and make it fast.{wizeGEEK.com}

grand isle joe

.....to think all these years I thought it was mermaids that pulled the ropes.......learn something new every day........:D:D

The weight at the end of the line is called a "monkey's fist."

Capt BJ has it exactly right, which I am sure he does not need me to say. It's a fairly routine evolution (event or exercise) since they do it so often. If you are able to get a vantage point far forward, you will see that the heaving line is already made up to (tied to) the hawser and everything is ready to go. Though I would like to see the guy who could throw a hawser!

The guns that fire the small line across use a plastic projectile that replaces the monkey's fist. These are used less frequently in civilian situations but they are used sometimes.

if your kids want to know, just tell them trained fish pull the ropes across to the guys waiting on the dock.:d:d

to be more technical, the "monkey's fist" is no longer used by naval forces or most commercial craft.

The monkey's fist knot used for the end of a heaving line was usually tied around a large nut to give it weight and allowed the heaving line to be thrown something like a bolo, by spinning and 'let fly'. http://www.wincingdevil.com/mf.htm

The monkey's fist prepared like this is heavy and hard; it carries far, but can do damage if it hits the intended receiver. I once saw one go through a car windsheild when overthrown .... ouch. Today a softer and somewhat larger poly ball covers a weight so as to minimize danger

This youtube video start with the small line being pulled by the shore workers. This small line is attached to the big line that holds the ship to the dock.

When I've cruised, it looks like this small line is "shot" to the shore crew from the ship, maybe with some type of air gun/cannon. As already said, this small line has some weight on the end of it to hold it on the shore once it is shot. The shore crew starts pulling on this small line, which has the big line attached to it. That's where this video starts.

When the ship is ready to depart, the ship releases the tension on the big line, the shore crew detaches the line, and the ship reels it in.

- 5 months later...

Havnt been on this site for a while,and just spotted this question.The smaller rope called a heaving line is attached to the heavy rope [hawser],using a bowline knot ,the heaving line is weighted at the end by a splice called a monkeys fist,this is a splice around a large steel nut to give the heaving line weight when it is thrown from ship to shore.

in extreme situations a line throwing gun can be used

http://www.hawills.com/lineguns.html

- 2 years later...

Sorry to join you in an old discussion but it is very interesting

The technique of the heaving line is highly symbolic : you use a small thing (a rope of 2 or 3 pounds) to move a hawser able to make move a boat of thousands tons !

I found your discussion when looking for a translation of these terms, as a french guy

In french :

the throwing gun is "le lance-amarre"

the knot is "la pomme de touline"

the heaving line (rope + knot) is "la touline"

the rope only is "le mandeur"

Does anybody know translations of these terms in other laguages (italian ?) or a dictionnary specialized in the transaltion of such terms of marine in different languages ???

Vampire Parrot

Cruise ships can and do position themselves with high accuracy against a dock without use of the lines. The lines will be sent ashore before the ship touches the dock, but there won't be made tight until the ship is in the required position.

Sometimes the spring lines may be used to help move the ship slightly along the dock, for example if a bollard on the quay would interfere with a gangway.

It's fascinating to watch the lines go ashore.... and I'm amazed at just how far some of the sailors can throw the monkeys fist!

navybankerteacher

When the ship nears the pier a "heaving line" (a very light weight rope with a weight - a "monkey's fist" - at the end) is thrown to the line handlers on the pier. The line handlers then haul in the heaving line, which is often attached to a somewhat heavier line: the "messenger line", which is used to haul the much heavier mooring line to the pier. Sometimes the heaving line also serves as the messenger line.

Originally these thick ropes were made of hemp, sisal or manila and were stiff and heavy, especially when wet. Modern ropes are made of synthetic materials, typically nylon, polypropylene or polyester. More recently, Dyneema® has become a popular synthetic material. These synthetics are lightweight, very flexible, and are waterproof so they float, making them much easier to handle than traditional natural material ropes. You can see the benefits of these ropes in the video link posted by Jimnbigd. They are also stronger, and have a longer usable life span.

And just as a reminder, as it was mentioned above, those big ropes are known as "lines".

Now, can anyone one tell me what a "spring line" is?

MommaBear55

Spring line goes from the bow to the stern (May be multiple lines) that attach to the dock and keep the boat or ship from being pulled away from the dock by tides or winds. (My husband is a master mariner as well as a merchant marinerand retired navy)

Spring lines go both ways: aft from the bow to the pier and forward from the stern to the pier. At times there will also be breast lines which do not run either forward or aft, but straight across to the pier. Finally, no lines go to the "dock": the "dock" is actually the space the ship occupies when it is alongside the pier - it is a "chunk" of water whose place the ship fills when alongside a pier. That is why a drydock is called dry - the water gets removed.

[ If there was a "like" button on cruisecritic then navybankerteacher and Capt_BJ would be getting a whole load of them :cool: ]

There is a pretty good description of spring lines, bow lines and stern lines on http://maritime.about.com/od/Vessel_Operations/a/Dock-Line-Terms-And-Best-Practices-For-Securing-Your-Boat.htm

A cruise ship will obviously have multiple lines holding it in place, from what I've seen a typical configuration for a cruise ship of say 90000 tons in calm weather is four stern lines, two forward spring lines, two aft spring lines and four bow lines.

Please sign in to comment

You will be able to leave a comment after signing in

- Welcome to Cruise Critic

- Hurricane Zone 2024

- Cruise Insurance Q&A w/ Steve Dasseos of Tripinsurancestore.com June 2024

- New Cruisers

- Cruise Lines “A – O”

- Cruise Lines “P – Z”

- River Cruising

- Cruise Critic News & Features

- Digital Photography & Cruise Technology

- Special Interest Cruising

- Cruise Discussion Topics

- UK Cruising

- Australia & New Zealand Cruisers

- Canadian Cruisers

- North American Homeports

- Ports of Call

- Cruise Conversations

Announcements

- New to Cruise Critic? Join our Community!

Write Your Own Amazing Review !

Click this gorgeous photo by member SUPERstar777 to share your review!

Features & News

LauraS · Started 14 hours ago

LauraS · Started Thursday at 09:33 PM

LauraS · Started Thursday at 04:47 PM

LauraS · Started Thursday at 02:09 PM

LauraS · Started Wednesday at 11:07 AM

- Existing user? Sign in OR Create an Account

- Find Your Roll Call

- Meet & Mingle

- Community Help Center

- All Activity

- Member Photo Albums

- Meet & Mingle Photos

- Favorite Cruise Memories

- Cruise Food Photos

- Cruise Ship Photos

- Ports of Call Photos

- Towel Animal Photos

- Amazing, Funny & Totally Awesome Cruise Photos

- Write a Review

- Live Cruise Reports

- Member Cruise Reviews

- Create New...

Kohinoor Ropes

- SHIPPING & MARINE

- YACHT & LEISURE MARINE

- INDUSTRIAL MARINE

- FISHING & AQUACULTURE NETS

- SAFETY & MOUNTAINEERING

- SPORTS NETS

- SUSTAINABILITY

- Merger Notice

How to Choose the Right Type of Mooring Rope for Your Boat and Sea-Faring Needs

1 March, 2023

Choosing the right type of mooring rope for your boat and sea-faring needs is an important decision that can impact the safety and security of your vessel. Here are some factors to consider when selecting a mooring rope:

- Mooring Rope Material: Mooring ropes can be made from a variety of materials, including nylon, polyester, polypropylene, and natural fibres such as manila or hemp. Each material has its own unique properties, such as strength, stretch, and resistance to abrasion or UV rays. Nylon is a popular choice for mooring ropes because it is strong, durable, and has good shock-absorption properties.

- Mooring Rope Diameter: The diameter of the rope is another important factor to consider, as it can impact the strength and weight of the rope. Thicker ropes are generally stronger, but also heavier and more difficult to handle. The recommended diameter of the rope will depend on the size and weight of your boat, as well as the conditions in which it will be used.

- Length of Mooring Rope: The length of the mooring rope will depend on the size of your boat and the depth of the water where it will be anchored. As a general rule, the length of the rope should be at least twice the depth of the water.

- Construction of Mooring Rope: Mooring ropes can be constructed in different ways, such as braided, twisted, or plaited. Braided ropes are strong and durable, while twisted ropes are more flexible and easier to handle. Plaited ropes are similar to braided ropes but have a smoother finish and less twisting.

- Purpose of Mooring Rope: Consider the purpose for which you will be using the mooring rope. Will it be used primarily for anchoring your boat or for securing it to a dock or pier? The type of rope that you choose may vary depending on the specific purpose.

- Environment Effect on Mooring Rope: Consider the environment in which the rope will be used. Will it be exposed to saltwater, UV rays, or harsh weather conditions? Some materials are more resistant to these factors than others, so choose a rope that can withstand the specific conditions in which it will be used.

By considering these factors, you can choose the right type of mooring rope for your boat and sea-faring needs. It’s always a good idea to consult with a professional or experienced sailor to ensure that you are selecting the appropriate rope for your specific situation. Mooring ropes are used to secure a vessel to a dock, pier, or buoy, and they play a crucial role in ensuring the safety of the vessel and its crew.

Here are 10 possible uses for mooring ropes:

- Securing the vessel to a dock: The primary use of mooring ropes is to secure the vessel to a dock, preventing it from drifting away from the shore.

- Towing other vessels: Mooring ropes can be used to tow other vessels, particularly in emergency situations.

- Anchoring the vessel: In addition to anchoring the vessel with an anchor, mooring ropes can also be used to hold the vessel in place in calm waters.

- Controlling the vessel’s movement: By adjusting the tension on the mooring ropes, the crew can control the vessel’s position and movement in the water.

- Tying off to a buoy: When a dock or pier is not available, vessels can be tied off to a buoy using mooring ropes.

- Securing the vessel during rough weather: During rough weather, mooring ropes are essential for securing the vessel to prevent it from being damaged by strong winds and waves.

- Preventing collision with other vessels: Mooring ropes can be used to prevent a vessel from colliding with other vessels in the area.

- Providing stability during loading and unloading: Mooring ropes are used to provide stability to the vessel during loading and unloading of cargo, ensuring the safety of crew members and preventing damage to the vessel.

- Attaching fenders: Fenders are used to protect the vessel from damage when it comes in contact with a dock or pier. Mooring ropes are used to attach the fenders to the vessel.

- Emergency rescue operations: Mooring ropes can be used to conduct emergency rescue operations, such as rescuing a person who has fallen into the water.

Mooring ropes are a crucial part of yacht maintenance. Kohinoor mooring ropes are designed to suit the requirements of various mooring activities. Kohinoor ropes are available in various lengths and diameters to meet your needs, ranging from general-purpose nylon rope that hardens in water to very tough dock line mooring rope. All sizes and types of large ships, including yachts, cruise ships, dry cargo, and wet cargo, prefer to use Kohinoor mooring ropes. Also, provide top-notch ship ropes for dredging, huge ships, tugs, towing, and ferry boats. Kohinoor heavy mooring ropes are extremely durable due to their high breaking strength, strong abrasion resistance, and UV stabilisation. The mooring ropes have ISI markings and have been DNV MEG4 approved. A reputable manufacturer and supplier of high-quality ship mooring ropes, working with B2B clients both domestically and internationally. Currently on new advances in this area and make every effort to give our customers the best technology available. Achieve higher levels of performance with the aid of our solutions.

Features of Kohinoor Mooring Ropes

- Excellent Strength.

- Fully UV stabilised with medium to low elongation to use.

- Protected spliced eyes at each end.

- Tremendous range of applications.

- Manufactured in accordance with OCIMF guidelines.

How to splice 12 strand mooring rope?

Splicing a 12-strand mooring rope requires some specialised knowledge and skills. Here is a basic overview of the process:

- Prepare the rope: Cut the rope to the desired length and tape the ends to prevent fraying.

- Unlay the strands: Carefully separate the strands of the rope by unlaying them from the end to the point where you want to splice. Be sure to keep the strands in order.

- Taper the strands: Taper the ends of each strand by removing some of the fibres. This will make it easier to work with and help the strands lay neatly when spliced.

- Form the splice: Fold the strands back on themselves to create a loop. Pass the strands through each other to create a tight, interlocking splice. The exact method will depend on the type of splice you are doing.

- Tuck the strands: Tuck the ends of the strands back into the rope using a fid. Work each strand in turn, making sure that they are snug and neat.

- Trim the ends: Cut off any excess rope and trim the ends of the strands to a uniform length.

- Finish the splice: Finally, whip the end of the rope with twine or tape to prevent fraying and secure the splice. It’s important to note that splicing a mooring rope is a complex task that requires specialised knowledge and experience. If you are not familiar with the process, it is best to seek the advice of a professional rigger or marine supplier.

How to splice 8 strand mooring rope?

Splicing an 8-strand mooring rope is similar to splicing a 12-strand rope but requires a slightly different approach. Here are the basic steps to splice an 8-strand mooring rope:

- Form the splice: With 8-strand rope, a splice is typically formed by weaving the strands together in an “over one, under one” pattern. To begin, take the first strand and weave it over the second, under the third, over the fourth, and so on. Then, take the second strand and weave it under the first, over the third, under the fourth, and so on. Continue this pattern with each of the remaining strands.

- Tuck the strands: Once you have woven the strands together, tuck the ends back into the rope using a fid. Work each strand in turn, making sure that they are snug and neat.

- Finish the splice: Finally, whip the end of the rope with twine or tape to prevent fraying and secure the splice. As with any rope splicing, it’s important to take your time and ensure that each step is done correctly. If you are new to splicing, it’s a good idea to practice on a short length of rope before attempting to splice a longer length for actual use.

Nylon ropes are known for their strength, durability, and shock-absorption properties, making them ideal for mooring. Polyester ropes are less stretchy than nylon but offer excellent resistance to abrasion and UV degradation, making them suitable for more static applications. Polypropylene ropes are lightweight, float on water, and resist rot and mildew, but they are less strong and have lower UV resistance than nylon or polyester ropes.

The appropriate length and diameter of mooring rope will depend on the size and weight of your boat, as well as the conditions in which it will be used. As a general rule, the length of the rope should be at least twice the depth of the water. Consult your boat manufacturer or a marine professional for specific recommendations based on your boat’s specifications.

Inspect your mooring ropes regularly for signs of wear, such as fraying, discoloration, or stiffness. The frequency of inspection will depend on how often you use your boat and the environmental conditions. Replace the ropes when you notice significant wear or at the manufacturer’s recommended intervals.

When storing mooring ropes, coil them neatly and keep them in a cool, dry place, away from direct sunlight or heat sources. This will help prevent deterioration caused by exposure to UV rays, moisture, or temperature fluctuations.

Yes, you can use different materials for your mooring ropes, depending on your specific needs and preferences. For example, you might choose a nylon rope for its shock-absorption properties when securing your boat to a dock, while using a polyester rope for its abrasion resistance when anchoring. Always consult a marine professional or experienced sailor for guidance on the best combination of materials for your specific situation.

Leave a comment Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

This is the Cookie Policy for Kohinoor Ropes, accessible from www.kohinoorrope.com

What Are Those Metal Pieces Attached To A Cruise Ship Mooring Line?

Have you ever walked by a cruise ship and wondered what those metal pieces were that are attached to the mooring lines? Sometimes these are shaped like round discs and other times they have a more geometric pattern but one thing is for sure ... you'll always see them attached. The surprising answer is that these are an important first line of defense against rats and other rodents being able to enter the ship.

Most modern ports that cruise ships dock at will not have major rodent problems but historically, pier areas around the world were a haven for rodents due to crates of food, packing materials, and other items that both offered excellent homes as well as food to rats, mice and other rodents. In fact, rats became a global species due to finding their way onto ships as they traveled around the world.

This causes numerous issues for sailors as well as other ports since these vermin not only can easily spoil food and water and damage cargo, but they can also spread disease.

Aside from hitching a ride on a pallet being loaded onto a ship, the easiest path of entry to a ship has historically been by scurrying along the mooring lines. Today's two dominante types of rats originated from India and China thousands of years ago and as global shipping expanded they quickly spread to virtually every city in the world. The only continent where rats do not currently exist is Antarctica.

Metal (and sometimes plastic) rat guards are now a virtually universal accessory for mooring lines ranging from smaller ocean going vessels to the largest cruise ships and cargo ships as well. While these seem a very low-tech solution that should have been implemented centuries ago, the earliest patents for moorign line rat gaurds didn't appear until the early 1900's and the ASTM Standard Specification for Rat Guards on ships wasn't established until 1960. Obviously these two events were well after rats established an irreversable foothold in every port city around the globe.

As you travel from port to port you may notice different vessels use different styles of rat guards. Some are round discs that close completely around the mooring lines so that the top as well as bottom of the line is covered, while others simply sit on top of the line.

Unfortunately these rat guards are not a perfect solution - though they are nearly perfect when used properly. For instance, in 2019, Carnival Freedom was cited by the CDC's 'Green Sheet Score' for their rat guards on the forward mooring lines not being effective for the prevention of rats and other pests that may want to enter the vessel. This was due to the rat guards having a large gap under the line.

Are You Ready For A Cruise?

Please fill out the form below and Heather from Flow Voyages (or a representative from CruiseWestCoast.com) will contact you as soon as possible.

For immediate help, please contact Heather directly: 630-779-9301 or : [email protected]

This is very important to consider since it isn't good enough to simply throw a piece of metal on the lines. You must make sure that it fits properly so that a rodent can't squeeze its way past the barrier and enter the ship. Rats are very sneaking creatures and will take any advantage they can to find new environemnts filled with food and shelter.

While it is extremely rare, YES ... just as you will find bugs that manage to find their way onto a cruise ship, sometimes you'll find rats and mice on a cruise ship as well. This is very rare but it is one reason why these rate guards are still an important first line of defence.

While cruise ship operators can't prevent rats from spreading, these rat guards are an important layer of protection that helps slow the spread of vermin and more importantly prevents the pests from interfearing with maritime operations.

So next time you walk by a cruise ship and see these devices, make sure to stop and take a look and think about the important role these guards play in keeping us safe and happy as we enjoy our cruise vacation.

VIDEO

COMMENTS

How is a mooring rope for a cruise ship made?Monster Machines is a program about the creation and organization of the giants of modern engineering. Full Docu...

Cruise ships. Inland ships. Dyneema® enables ... Find out how ropes made with Dyneema® fiber have revolutionized mooring efficiency for some of the world's biggest ships. Case study. 25 Oct 2023 ... Our premium mooring rope partners are dedicated to manufacturing strong, safe, and reliable mooring and towing lines with Dyneema® SK78 fiber ...

Rope Inc. has been a Commercial Marine and Cruise Ship industry supplier for more than twenty years. Rope Inc. offers customers an array of options for Towing and Mooring Lines in Polypropylene, Polyolefin copolymer, Nylon, and Polyester. Sizes range from 1" up to 4". Super Dan mooring ropes and Blue Steel mooring ropes come standard 220m ...

the next biggest cruise ship currently afl oat. When the Oasis of the Seas was launched in late 2009, it was the fi rst ever Royal Caribbean ship to use mooring ropes with Dyneema® rather than the normal mixture of polypropylene (PP) and polyester (PET). Given the size and importance of the ship, STX originally proposed to RCCL that ropes ...

The figure shows a ship moored (made fast) alongside a wharf. The moorings in the figure are named as follows: There may be two, three or even four ropes or wires. The should lead at least 45 degree on the bow. A rope/wire, which leads as near 90 Degrees to the ship's fore and aft line as possible.

From epic container ships and tankers to cruise ships and tugboats, thousands of vessels over the last couple of decades have been equipped with mooring lines made with Dyneema ® SK78 fiber for ...

For Dynamica Mooring & Towing ropes, we recommend protecting your rope with either a braided polyester - or Dyneema® cover. The covers can be applied as follows. In the soft eyes. In the soft eyes and over the splice. In the soft eyes, over the splice in an agreed distance towards the middle of the rope. On the entire length.

The strength required by a ship's mooring system is also known as the Ship Design Minimum Breaking Load (Ship Design MBL) (OCIMF). This is the core parameter against which the mooring ropes should be dimensioned. When selecting a mooring rope for a specific vessel, the LDBF of the rope must be equal to or greater than the Ship Design

The right rope for the right application. Mooring has significant operational demands, which is why our synthetic rope solutions not only equal the strength and durability of steel wire, they also allow for fewer crew members, shorter mooring operations, and safer, easier handling. For more information on line selection watch our video on ...

We give a snapshot of the relevant regulatory framework governing the mooring process and mooring equipment (including ropes), and the key concepts they introduce. Find out the risks and pain points of non-compliance and how best to comply with regulations like the upcoming SOLAS Regulation II-1/3-8 by only using certified ropes that are fit for purpose, alongside an effective Line Management ...

In the history of ship mooring, diameter has often been the only criterium in the selection of ropes. Today, it is still commonly used to compare mooring ropes, with common advice being that thicker ropes should be chosen for heavier vessels. ... Cruise. The Acera™ range of HMPE ropes is one of the preferred choices for the largest and most ...

Ten Horn - Mooring Winch. WireCo WireGroup - Synthetic & Wire Ropes. Yale - Synthetic Ropes. Contact Roger Underwood for more information. Nance & Underwood Rigging and Sails. 262 SW 33rd Street · Fort Lauderdale Florida 33315. Ph: 954-764-6001 · Fax: 954-764-5977 · Toll Free: 800-328-9782.

Some very common methods of mooring are Mediterranean mooring, Baltic mooring, Running mooring, Standing mooring, Spider mooring buoys, Single-point or single buoy mooring, Conventional or multi buoy mooring, Ship to Ship Mooring. While Moored alongside a fixed or floating jetty or a sea berth there are various forces acting on the vessel such ...

Havnt been on this site for a while,and just spotted this question.The smaller rope called a heaving line is attached to the heavy rope [hawser],using a bowline knot ,the heaving line is weighted at the end by a splice called a monkeys fist,this is a splice around a large steel nut to give the heaving line weight when it is thrown from ship to ...

Here are the basic steps to splice an 8-strand mooring rope: Prepare the rope: Cut the rope to the desired length and tape the ends to prevent fraying. Unlay the strands: Carefully separate the strands of the rope by unlaying them from the end to the point where you want to splice. Be sure to keep the strands in order.

Survitec Group is a leading supplier of mooring ropes to the commercial marine industry with an enviable reputation for quality, technical support and product innovation. We supply the ropes used by tankers and cargo vessels, cruise ships and ferries, tug and salvage operators, offshore oil and gas contractors, naval ships and port authorities.

The Premium Ropes Eco Dock is our first rope made from 100% recycled plastic. This dockline is braided with rPet yarns. These are made from the waste of the most common type of plastic Pet. The Eco Dock is perfect for mooring, docking but also anchoring. It has great elongation characteristics that protects your boat from rough weather conditions.

Usually rat guards are spinning freely on the mooring lines, but not always. Image credit: U.S. Navy photo via Wikimedia. These disks can be noticed on military and civilian ships, on cruise ships ...

Metal (and sometimes plastic) rat guards are now a virtually universal accessory for mooring lines ranging from smaller ocean going vessels to the largest cruise ships and cargo ships as well. While these seem a very low-tech solution that should have been implemented centuries ago, the earliest patents for moorign line rat gaurds didn't appear ...

by Rich Thomaselli. Last updated: 2:25 PM ET, Tue July 18, 2023. That must have been a mighty wind. Norwegian Cruise Line's Norwegian Prima cruise ship broke away from its mooring ropes due to strong winds in Zeebrugge, Belgium over the weekend. Although a gangway fell into the water, nobody was injured, a Norwegian spokesperson confirmed.

The strength required by a ship's mooring system is also known as the Ship Design Minimum Breaking Load (Ship Design MBL) (OCIMF). This is the core parameter against which the mooring ropes should be dimensioned. When selecting a mooring rope for a specific vessel, the LDBF of the rope must be equal to or greater than the Ship Design MBL to ...

During exceptionally windy weather while docked in Zeebrugge, Belgium on Saturday, July 15, 2023, Norwegian Prima broke free of several mooring ropes and began drifting away from the pier. The ...

Technical Articles and Whitepapers. List of Technical Articles for Mooring Ropes. Why using unverified anti snap-back solutions can be a serious threat to safety in mooring operations. Read Article. Water absorption in polyamide tails can cause their weight to increase by 50%. Read Article. Digital rope management with all-in-one LMP application.