Onboard Experience

Secrets of cruise ship stability: unlocking the science behind upright sailing.

As a person with a deep passion for cruise ships, I am continuously amazed by the exceptional engineering that allows these massive vessels to stay balanced and move smoothly through the water. It truly is a marvel of science and technology, and right now, I’m excited to delve into and uncover the secrets behind the stability of cruise ships.

You see, these floating behemoths defy gravity and gracefully glide through the water, providing a luxurious and comfortable experience for thousands of guests. But how do they do it? Well, it all comes down to a delicate balance of buoyancy, hull design, and careful engineering considerations.

By understanding the principles of buoyancy and stability, as well as the intricacies of hull design, we can truly appreciate the science behind upright sailing. So, join me as we delve into the hidden world of cruise ship stability and uncover the fascinating secrets that keep these incredible vessels afloat.

Table of Contents

Key Takeaways

- Cruise ships stay afloat by having an average density less than that of air.

- The ship’s center of gravity is lower due to heavier machinery and fuel stores.

- The round-bottom hull shape helps the ship move smoothly through the water and increases stability.

- Ballast tanks allow for adjustments in stability during rough seas.

How do cruise ships stay afloat?

I know that cruise ships stay afloat by having an average density less than that of air, and the weight of the ship is balanced by the buoyancy force.

The effects of weather conditions on cruise ship stability are mitigated by the role of technology in maintaining cruise ship buoyancy. The ship’s center of gravity is kept low due to the heavier machinery and fuel stores, ensuring stability even in rough seas. Additionally, the round-bottom hull design enhances stability and minimizes drag, preventing swaying and rocking.

The ship’s density, determined by the materials it’s made of, plays a crucial role in its ability to float. Engineers carefully consider these factors during the design process to ensure the ship stays upright and afloat. Technology and design work hand in hand to maintain the buoyancy of cruise ships, allowing passengers to enjoy a smooth and stable sailing experience.

Principles of buoyancy and stability

Buoyancy and stability are essential principles that ensure a cruise ship stays afloat and upright. To achieve this, the ship’s center of gravity and weight distribution play a crucial role. By strategically placing heavier machinery and fuel stores lower in the ship, the center of gravity is lowered, enhancing stability. This prevents the ship from tipping over even when faced with external forces like wind.

Additionally, ballast tanks play an important role in maintaining the ship’s stability. These tanks can be filled or emptied to adjust the ship’s weight distribution, counteracting the effects of waves and rough seas. In rough conditions, the ballast tanks can be pumped to one side, effectively countering the forces acting on the ship and maintaining balance.

To provide a visual representation of these principles, here is a table summarizing the key points:

Understanding and implementing these principles, along with careful engineering and design considerations, ensure that cruise ships remain safe, stable, and able to navigate through various conditions.

Hull design and stability

Little did I know, the sleek and rounded hull of a cruise ship isn’t just for show, but actually serves a vital purpose in maintaining stability on the open seas.

The efficiency of round bottom hulls plays a crucial role in the ship’s ability to move smoothly through the water. The rounded edges of the hull increase stability and prevent swaying and rocking, minimizing the effects of rough seas and reducing seasickness.

Additionally, the round-bottom hull shape enhances stability by minimizing drag, allowing the ship to maintain its upright position even in windy conditions. While boats with v-shaped hulls may be faster, the design considerations for cruise ships prioritize stability and comfort for the passengers.

The combination of the round bottom hull and careful design choices ensures that the ship can navigate the seas with ease and maintain a steady course.

Frequently Asked Questions

How do ballast tanks help maintain a cruise ship’s stability.

Ballast tanks are essential for stability management on a cruise ship. By filling or emptying these tanks, the ship can adjust its weight distribution, counteract waves, and maintain balance during rough seas.

What factors contribute to the low center of gravity in cruise ships?

Factors contributing to the low center of gravity in cruise ships include the weight distribution of machinery and fuel stores, which helps maintain stability. This, combined with careful design considerations, ensures the ship remains upright and stable during its voyage.

How do cruise ships manage weights to stay upright?

To stay upright, cruise ships manage weights through managing cargo and utilizing stabilizing systems. This includes careful distribution of weight, utilizing ballast tanks, and optimizing the ship’s center of gravity.

What are some design considerations for mega cruise ships?

Design challenges for mega cruise ships include accommodating thousands of guests while maintaining stability. Safety measures, such as a low center of gravity, round-bottom hull shape, and ballast tanks, are implemented to ensure the ship stays upright during rough seas.

Can the shape of the hull affect a cruise ship’s stability in rough seas?

Yes, the shape of the hull can significantly impact a cruise ship’s stability in rough seas. A round-bottom hull shape enhances stability, minimizes drag, prevents swaying and rocking, and reduces seasickness.

Meet Asra, a talented and adventurous writer who infuses her passion for exploration into every word she writes. Asra’s love for storytelling and her insatiable curiosity about the world make her an invaluable asset to the Voyager Info team.

From a young age, Asra was drawn to the power of words and their ability to transport readers to far-off lands and magical realms. Her fascination with travel and cultures from around the globe fueled her desire to become a travel writer, and she set out on a journey to turn her dreams into reality.

The Ultimate Guide To First-Time Cruises: Unveiling The Perfect Options

Staying Connected At Sea: Cell Phone Coverage And Communication Options On Cruise Ships

Meet Asra, a talented and adventurous writer who infuses her passion for exploration into every word she writes. Asra’s love for storytelling and her insatiable curiosity about the world make her an invaluable asset to the Voyager Info team. From a young age, Asra was drawn to the power of words and their ability to transport readers to far-off lands and magical realms. Her fascination with travel and cultures from around the globe fueled her desire to become a travel writer, and she set out on a journey to turn her dreams into reality.

You may like

Regal princess: poolside fun, chocolate delights, and nightlife.

Upon stepping onto the magnificent Regal Princess, I am immediately captivated by the vast array of entertainment options at my disposal.

The poolside theater, boasting a screen 30% larger than other Princess ships, promises to immerse me in larger-than-life movie experiences. And as the sun sets, the pools transform into a mesmerizing watercolor fantasy, complete with dancing fountains and interactive light effects.

With the tantalizing aroma of freshly baked pastries wafting through the air, and the promise of indulging in chocolate delights crafted by renowned pastry chefs, the Regal Princess is a true haven for those with a sweet tooth.

But the excitement doesn’t end there; the ship also boasts vibrant nightlife options, including a pulsating dance club and elegant bars and theaters.

As I embark on this unforgettable journey, I am eager to explore the unique attractions this ship has to offer, such as the breathtaking SeaWalk and the tranquil Retreat Pool that transforms into a chic South Beach-style club at night.

Get ready to dive into a world of poolside fun, chocolate delights, and electrifying nightlife aboard the Regal Princess.

- Princess signature poolside theater with a 30% larger screen on Regal Princess

- Interactive sound and light effects with dancing fountains in the evening transformation of top deck pools into Princess WaterColor Fantasy

- Pastry Shop and Chocolate Journeys experience with freshly baked goodies and demonstrations by Princess pastry chefs, featuring renowned chocolatier Norman Love

- Club 6 as a lively dance club at night with a resident DJ and bartenders, and the elegant Piazza area hosting shows and other bars

Princess Poolside Theater: A Larger-than-Life Experience

I love how the Princess Poolside Theater on the Regal Princess offers a larger screen, making the movie experience larger-than-life. This enhanced movie experience is perfect for enjoying a film under the stars while lounging by the pool.

The Princess poolside theater features day and night showings of movies, concerts, and even sporting events. But what truly sets it apart are the WaterColor shows with live music. These shows are a feast for the senses, combining interactive sound and light effects with dancing fountains.

Imagine watching a movie or concert while being surrounded by a mesmerizing water and light display. It truly takes the entertainment to another level.

Whether you’re a movie lover or a music enthusiast, the Princess poolside theater is a must-visit on the Regal Princess.

WaterColor Fantasy: Immersive Poolside Entertainment

During the day and night, enjoy the immersive WaterColor Fantasy experience with interactive sound and light effects, dancing fountains, and captivating shows set to the tunes of Frank Sinatra or Michael Jackson.

As the sun sets, the poolside area comes alive with vibrant colors and enchanting music. The interactive fountain experience mesmerizes the audience, with water jets dancing in sync to the rhythm.

The sound effects create an immersive atmosphere, making you feel like you’ve stepped into a magical world.

The watercolor shows transport you to different realms, with each performance telling a unique story. From elegant ballet performances to energetic pop numbers, the shows cater to a variety of tastes and preferences.

Immerse yourself in the wonder of the WaterColor Fantasy experience, where art and entertainment blend seamlessly, leaving you awestruck and wanting more.

Indulge in Pastry Delights: The Hidden Corridor of Goodies

Nestled within the ship, a hidden corridor is filled with an array of freshly baked pastries and delectable treats. This hidden gem is a pastry shop extravaganza, offering a haven for those with a sweet tooth.

As you wander through the corridor, the aroma of warm croissants and French toast fills the air, tempting you to indulge in a decadent breakfast. For lunch or dinner, the pastry shop delights with vogue desserts that are as visually stunning as they are delicious.

Princess pastry chefs can be found conducting demonstrations, sharing their expertise and passion for baking. This hidden corridor is also part of the Chocolate Journeys experience, with renowned chocolatier Norman Love showcasing his delectable chocolates.

Whether you’re a pastry connoisseur or simply looking for a sweet treat, this hidden corridor of delights is a must-visit on the Regal Princess.

Chocolate Journeys: A Sweet Adventure on Regal Princess

As I explore the ship, I can’t resist the temptation of indulging in the decadent treats and demonstrations of the Chocolate Journeys experience on board.

The Chocolate Journeys program offers a sweet adventure for chocolate lovers like me. One of the highlights is the chocolate workshops where I can learn the art of chocolate making from the experts. Renowned chocolatier Norman Love’s creations are showcased during these workshops, and I am in awe of the intricate designs and flavors he creates.

From rich truffles to delicate bonbons, each bite is a burst of pure bliss. The demonstrations are not only informative but also interactive, allowing me to appreciate the craftsmanship behind these delectable treats.

The Chocolate Journeys experience on Regal Princess truly takes me on a journey of indulgence and delight.

Club 6: The Ultimate Nightlife Destination

I love the energetic atmosphere at Club 6, where the DJ keeps the dance floor alive with beloved hits and the bartenders mix up delicious cocktails.

Club 6: Top notch entertainment

The resident DJ creates a lively atmosphere with an incredible selection of dance hits.

The vibrant dance floor experience is unmatched, with people of all ages and backgrounds coming together to let loose and have a great time.

Vibrant dance floor experience

The energy is contagious as the crowd moves to the beat, their bodies pulsating with the music.

The colorful lights and state-of-the-art sound system enhance the overall experience, making it truly unforgettable.

Club 6 is the pulse of the night, where everyone comes to dance, socialize, and enjoy top-notch entertainment. It’s the perfect place to let go and immerse yourself in the vibrant atmosphere.

The DJ’s playlist is carefully curated to keep the energy high and the dance floor packed. The bartenders are masters of their craft, mixing up delicious cocktails that complement the lively ambiance. Whether you’re a seasoned dancer or just looking to have a good time, Club 6 offers a vibrant dance floor experience that will leave you wanting more.

Piazza Nightlife: Elegance and Excitement Combined

The Piazza comes alive at night with a vibrant and elegant atmosphere, offering a variety of bars and theaters hosting exciting shows.

As I step into the Piazza, I am immediately enveloped by the classy cocktails and vibrant atmosphere. The sound of live music fills the air, drawing me towards the dance floor frenzy.

The Piazza is bustling with energy as people gather to enjoy the night’s entertainment. The bars are adorned with elegant decor, and the bartenders skillfully craft delicious and creative cocktails. The live music sets the perfect mood, inviting everyone to let loose and dance the night away.

Whether you’re in the mood for a relaxing evening sipping classy cocktails or ready to hit the dance floor, the Piazza nightlife offers an unforgettable experience in a vibrant and lively setting.

SeaWalk: Walking on Air Above the Ocean

Walking along the SeaWalk, I am in awe of the breathtaking views of the ocean below. The SeaWalk, extending 28 feet beyond the edge of the ship, is a glass-paneled walkway that offers clear views of the vast expanse of water. It’s like walking on air above the ocean, feeling the gentle breeze and hearing the soothing sound of the waves. At night, the SeaWalk is illuminated, creating a funky walkway that leads past the SeaView Bar. This unique bar experience, not found on land, serves tropical cocktails with impressive bartending skills. As I sip on my drink, I can’t help but feel a sense of wonder and excitement, knowing that I am enjoying a drink while being surrounded by the beauty of the sea.

SeaView Bar: A Unique Bar Experience at Sea

Sipping on a tropical cocktail at the SeaView Bar, I can’t help but marvel at the unique bar experience and impressive bartending skills. The mixology magic happening behind the bar is truly captivating.

The atmosphere here is incredible, with ocean sunset vibes that transport you to a place of pure relaxation. As I sit here, enjoying my drink, I can’t help but notice the attention to detail in every aspect of the bar. From the beautifully crafted cocktails to the stunning views of the ocean through the glass-paneled walkway, everything about the SeaView Bar is designed to create an unforgettable experience.

The bartenders here are true artists, skillfully mixing ingredients to create drinks that are not only visually stunning but also bursting with flavor. This is a bar experience unlike any other, where you can truly indulge in mixology magic while surrounded by the breathtaking beauty of the ocean.

Retreat Pool: Your Oasis of Tranquility by Day

Lounging by the Retreat Pool during the day, I feel a sense of tranquility wash over me as I soak up the sun and enjoy the peaceful atmosphere. The Retreat Pool is an oasis of calm, with its adults-only policy ensuring a serene and relaxing experience.

The poolside furniture is comfortable and inviting, perfect for lounging and unwinding. As I take in the surroundings, I notice the Retreat Bar nearby, offering a variety of refreshing drinks. But what catches my attention the most are the picnic basket options available.

The gourmet lunches provided are a delightful treat, with a range of delicious and satisfying options to choose from. It’s the perfect way to indulge in a delicious meal while enjoying the serenity of the Retreat Pool.

Night Sky Lounge: Unforgettable Nights at Sea

After a day of tranquil relaxation by the Retreat Pool, the night on the Regal Princess comes alive in the vibrant Night Sky Lounge.

As I enter the lounge, I am immediately captivated by the unforgettable entertainment and chic club atmosphere. The lounge transforms into a stylish South Beach-style club, complete with atmospheric pool and furniture lighting, glowing drinks, and a pulsating DJ.

The energy is contagious as guests dance the night away under the starry sky. The Night Sky Lounge is the perfect place to let loose and have a great time with friends or meet new people from around the world.

From beloved dance hits to trendy beats, the resident DJ keeps the party going all night long. With its stylish ambiance and lively entertainment, the Night Sky Lounge is an experience not to be missed on the Regal Princess.

Can Children Attend the Club 6 Dance Club at Night?

Yes, children are not allowed to attend the Club 6 dance club at night. The nightclub policy on the Regal Princess is for adults only, creating a lively atmosphere for dancing and enjoying cocktails.

Are There Any Vegetarian Options Available at the Princess Pastry Shop?

Yes, there are vegetarian treats available at the Princess pastry shop. They offer a variety of options like freshly baked croissants, French toast, and vogue desserts that are suitable for vegetarian guests.

Is There an Additional Cost for the Retreat Cabanas at the Retreat Pool?

Yes, there is an additional cost for the retreat cabanas at the retreat pool. As for children at the Club 6 dance club, it is an adults-only space, so children are not allowed.

Can Guests Bring Their Own Picnic Baskets to the Retreat Pool?

Yes, guests can bring their own picnic baskets to the retreat pool. They are welcome to enjoy their own food and have a relaxing meal by the pool.

What Types of Shows Are Typically Hosted in the Piazza Area?

The Piazza area hosts a variety of shows, including live music performances, theatrical productions, and dance shows. Poolside entertainment features movies, concerts, and sporting events shown on a larger screen.

Claire, a creative soul with an unquenchable thirst for storytelling, is an integral part of the Voyager Info team. As a dedicated writer, she weaves captivating narratives that transport readers to enchanting cruise destinations and beyond.

Claire’s love affair with writing began at an early age when she discovered the magic of words and their ability to craft worlds and emotions. Her innate curiosity led her to explore various literary genres, but it was travel writing that truly captured her heart. Drawing inspiration from her own globetrotting adventures and encounters with diverse cultures, Claire embarked on a journey to become a travel writer par excellence.

Ultimate World Cruise: Unforgettable Destinations and Luxurious Amenities

Ever since I can recall, I’ve harbored a deep desire to embark on the ultimate worldwide adventure, a voyage in which every new day reveals another breathtaking and extraordinary destination. Imagine steering through the Panama Canal, exploring the vibrant streets of Singapore, and being astonished by the ancient pyramids of Egypt.

This extraordinary journey offers not only unforgettable destinations but also luxurious amenities that ensure a truly indulgent experience. From first-class air transportation to onboard medical services, every detail has been carefully planned to make this the trip of a lifetime.

Join me as we set sail on this extraordinary adventure.

- The Ultimate World Cruise itinerary includes stops in various destinations around the world, such as the Caribbean, Mexico, San Francisco, Hawaii, French Polynesia, Australia, Southeast Asia, the Middle East, and the Mediterranean.

- The Pacific and Oceania destinations offer stunning landscapes, adventurous activities, pristine beaches, and overwater bungalows, providing endless opportunities for adventure and relaxation.

- The Australia and Southeast Asia stops allow travelers to explore the coast of Australia and experience the vibrant cultures of Indonesia, Singapore, Malaysia, and Thailand, including Bali’s stunning beaches and ancient temples.

- The Middle East and Mediterranean highlights include crossing the Andaman Sea to India, stopping in the United Arab Emirates, Egypt, Jordan, and other captivating destinations, and exploring ancient Egyptian temples and the culinary delights of the Mediterranean. Additionally, the cruise offers luxurious amenities such as first-class air transportation, door-to-door luggage service, a comprehensive visa package, and unlimited valet laundry and dry-cleaning services.

World Cruise Itinerary

I depart from Miami and embark on an incredible journey that takes me to Key West and the Caribbean, where I am greeted by crystal-clear waters and pristine beaches.

As the world cruise itinerary continues, I cross the iconic Panama Canal, marveling at the engineering marvel that connects the Atlantic and Pacific Oceans.

In Mexico, I immerse myself in the vibrant culture and explore ancient ruins.

Next, I head west towards San Francisco, where I am captivated by the iconic Golden Gate Bridge and the city’s vibrant atmosphere.

But the adventure doesn’t stop there. The Pacific and Oceania await, offering breathtaking destinations like Hawaii, French Polynesia, and New Zealand.

From stunning landscapes to diverse cultures, this world cruise promises unforgettable experiences at every turn.

Pacific and Oceania Destinations

Visiting Hawaii and French Polynesia on a world cruise is a dream come true. The Pacific and Oceania destinations are like no other.

Hawaii, known for its stunning landscapes and adventurous spirit, offers endless opportunities for a Hawaii adventure. From hiking volcanoes to snorkeling in crystal-clear waters, there is never a dull moment.

And then there’s French Polynesia, a true paradise on earth. With its pristine white sand beaches, turquoise lagoons, and overwater bungalows, it’s hard not to fall in love with this tropical haven. Whether you’re exploring the vibrant coral reefs or simply relaxing on the beach, French Polynesia is the perfect place to unwind and soak up the sun.

These two destinations truly embody the magic and beauty of the Pacific and Oceania region.

Australia and Southeast Asia Stops

Exploring the coast of Australia and experiencing the vibrant cultures of Indonesia, Singapore, Malaysia, and Thailand are some of the highlights of this incredible journey.

In Indonesia, attractions such as Bali’s stunning beaches and ancient temples await.

Singapore, known for its rich cultural heritage, offers a mix of Chinese, Malay, and Indian influences. The city-state’s diverse neighborhoods, like Chinatown and Little India, showcase its multiculturalism.

Malaysia entices with its bustling cities, lush rainforests, and delicious street food.

And in Thailand, the land of smiles, you can indulge in tropical paradises like Phuket and experience the grandeur of Bangkok’s temples.

Each destination along this world cruise offers a unique blend of history, natural beauty, and vibrant cultures that will leave you in awe.

Middle East and Mediterranean Highlights

Crossing the Andaman Sea to India and stopping in the United Arab Emirates, Egypt, Jordan, and other captivating destinations, the Middle East and Mediterranean portion of the cruise promises a fascinating blend of history, culture, and breathtaking scenery.

As I sail through the crystal-clear waters of the Andaman Sea, I am mesmerized by its beauty and tranquility.

The rich history of the Middle East comes alive as I explore ancient Egyptian temples and marvel at the awe-inspiring pyramids. In Jordan, I am in awe of the ancient city of Petra, carved into the rose-red cliffs.

And the culinary delights of the Mediterranean are a feast for the senses. From the aromatic spices of Egypt to the fresh seafood of Greece, I indulge in a gastronomic journey like no other.

The Middle East and Mediterranean highlights truly offer an unforgettable experience.

First-class Air Transportation

Flying in first-class on this world cruise is an incredible experience, with luxurious amenities and top-notch service. From the moment I stepped onto the plane, I was enveloped in an atmosphere of opulence and comfort.

The spacious seats, upholstered in plush leather, provided ample room to stretch out and relax. The attentive flight attendants catered to my every need, offering a selection of gourmet meals and fine wines.

As I reclined in my seat, I marveled at the state-of-the-art entertainment system, which offered an array of movies, TV shows, and games to keep me entertained throughout the journey.

With luxury travel, premium services, and a level of comfort that surpassed my expectations, flying first-class on this world cruise truly made me feel like a VIP.

Door-to-door Luggage Service

After enjoying the luxury of first-class air transportation, the next aspect of the ultimate world cruise that truly adds convenience and peace of mind is the door-to-door luggage service. Imagine not having to worry about lugging heavy suitcases through airports or worrying about lost or damaged baggage. With this service, your luggage is handled with utmost care from the moment you leave your home until it reaches your stateroom onboard the cruise ship.

To illustrate the benefits of this hassle-free travel experience, let me present you with a table:

This door-to-door luggage service ensures that you can focus on enjoying your journey without any worries. It’s just one more way the ultimate world cruise provides an unforgettable and stress-free experience.

Comprehensive Visa Package

When it comes to the comprehensive visa package, I can rest assured knowing that all the necessary arrangements and paperwork will be taken care of for me.

Visa requirements and processing can often be overwhelming and time-consuming, but with this package, everything is handled seamlessly.

From gathering the required documents to submitting the application, the process is efficient and stress-free.

The experts handling the visa processing are well-versed in the requirements of each destination on the world cruise itinerary.

They ensure that all the necessary information is provided and that any potential issues are addressed promptly.

With their assistance, I can focus on preparing for the exciting journey ahead, knowing that my visa needs are in capable hands.

Unlimited Valet Laundry and Dry-cleaning

I love the convenience of having unlimited valet laundry and dry-cleaning services on board the cruise ship. It’s one of the many luxurious amenities that make this world cruise truly unforgettable. Here are four reasons why these laundry perks are so amazing:

Effortless Convenience: With unlimited valet laundry, I don’t have to worry about doing laundry myself or finding a laundromat in each port. I simply leave my dirty clothes in a bag outside my cabin, and they magically reappear clean and pressed.

Time-Saving: Instead of spending precious vacation time doing laundry, I can relax and enjoy all the incredible destinations on our itinerary.

Fresh and Crisp Clothing: The professional laundry and dry-cleaning services ensure that my clothes always look impeccable. I feel confident and polished knowing that my garments are being treated with the utmost care.

Pack Light: Knowing that I have unlimited laundry services, I can pack lighter and bring more variety in my wardrobe. I can indulge in stylish outfits without worrying about running out of clean clothes.

These unlimited laundry perks truly elevate the experience of this world cruise, providing luxurious clothing care that adds an extra layer of comfort and convenience.

Are Meals Included on the Cruise?

Yes, meals are included on the cruise. There are a variety of meal options available to cater to different dietary restrictions. From breakfast to dinner, you’ll enjoy delicious and satisfying meals throughout your journey.

Can I Bring My Own Alcohol on Board?

Yes, you can bring your own alcohol on board. However, it’s important to note that there may be restrictions on the amount and type of alcohol allowed. Make sure to check the alcohol policy and prohibited items list before your trip.

Is There a Dress Code for the Ship’s Restaurants?

Yes, there is a dress code for the ship’s restaurants. It is important to follow the dress code etiquette to ensure an enjoyable dining experience. Make sure to adhere to the restaurant reservation policies as well.

Are There Any Age Restrictions for Passengers?

Yes, there are age restrictions for passengers on the cruise. It is best to check with the cruise line for specific guidelines when it comes to traveling with children.

Can I Bring My Pet on the Cruise?

Unfortunately, pets are not allowed on the cruise. But don’t worry, there are plenty of pet-friendly accommodations available on land. Make sure to check airline pet policies if you plan to bring your furry friend along.

Celebrating the 2023 Ryder Cup: Costa Cruises Partners With Golf’s Finest

I’m thrilled to share the incredible news that Costa Cruises, the leading cruise line worldwide, has established a partnership with the prestigious 2023 Ryder Cup golf tournament.

As an official sponsor, Costa Cruises is celebrating this remarkable event by introducing the Cruise & Golf program. With two cruise itinerary packages and 15 international courses to choose from, golf enthusiasts can explore the Mediterranean while experiencing the thrill of playing on world-class courses.

This unique partnership allows you to play a different course every day, creating an unforgettable golfing adventure.

- Costa Cruises is an official sponsor of the 2023 Ryder Cup golf tournament.

- Costa Cruises has introduced a new Cruise & Golf program, offering two cruise itinerary packages and 15 international courses to choose from.

- Guests on board Costa Smeralda’s seven-day Mediterranean itinerary can play courses in Italy, France, and Spain, with the option to play a different course every day.

- Costa Cruises offers two packages for golfing cruisers: the Birdie package, which provides access to three courses, and the Eagle package, which offers access to four courses. Both packages include various perks and amenities.

The Ryder Cup: A Prestigious Golf Tournament

I’m excited to learn that the Ryder Cup is a prestigious golf tournament that involves 12-member teams from the United States and Europe. The tournament has a rich history, dating back to 1927. Originally, it was a competition between the United States and Great Britain, but in 1979, it expanded to include all of Europe.

The Ryder Cup format consists of four-ball, foursomes, and singles matches over three days. This unique format creates intense competition and incredible moments on the golf course.

Hosting the Ryder Cup is a significant event for the local economy. It brings in a large number of visitors, boosts tourism, and generates revenue for hotels, restaurants, and businesses in the host city. The impact is felt not only during the tournament but also in the long term as the city gains exposure and becomes a desirable destination for future events.

Costa Cruises: Official Sponsor of the 2023 Ryder Cup

Excited to be the official sponsor of the 2023 Ryder Cup, Costa Cruises is offering golf enthusiasts the opportunity to experience the tournament and explore the Mediterranean with their Cruise & Golf program.

As an official sponsor, Costa Cruises plays a significant role in supporting and promoting this prestigious golf event.

Through their Cruise & Golf program, Costa Cruises provides golfers with a unique and convenient way to enjoy the Ryder Cup while also indulging in a luxurious cruise experience.

The program offers two itinerary packages and a selection of 15 international courses, allowing guests to play different courses every day.

With perks like priority embarkation, equipment storage, private transfers, and exclusive onboard offers, the Cruise & Golf program ensures that golfers have all they need for a seamless and memorable experience.

Cruise & Golf Program: A Unique Partnership Celebration

Thrilled to be a part of the Cruise & Golf program, I can’t wait to experience the unique partnership celebration between Costa Cruises and the Ryder Cup.

This exclusive golfing opportunity is truly a golfing extravaganza. Guests on board Costa Smeralda’s Mediterranean itinerary can enjoy playing courses in Italy, France, and Spain. With a variety of courses to choose from, golfers can play a different course every day.

Costa Cruises offers a foro-in-uno experience, allowing golfers to explore the Mediterranean on excursions or relax on board. The program offers two packages, the Birdie package providing access to three courses and the Eagle package offering access to four courses. Both packages come with priority disembarkation and embarkation, equipment storage and insurance, and a welcome kit in the cabin.

It’s an incredible opportunity for golf enthusiasts to combine their love of golf with a luxurious cruise experience.

Golfing Opportunities on Costa Cruises: Explore the Mediterranean

While exploring the Mediterranean on a Costa Cruises vacation, golfers can choose from a variety of courses in Italy, France, and Spain. Here are three reasons why these golfing excursions in historic European cities offer exclusive access to top-rated golf courses on the Mediterranean:

Wide Range of Courses: Costa Cruises provides golfers with a range of options in iconic cities such as Rome, Savona, Barcelona, Palma de Mallorca, and Marseille. With multiple courses available in each city, golfers can enjoy a diverse golfing experience.

Daily Variety: Guests can play a different course every day, ensuring a thrilling and varied golfing adventure throughout their cruise. This allows golfers to explore different landscapes and challenges, making their vacation truly memorable.

Unparalleled Convenience: Costa Cruises offers a seamless experience with their Cruise & Golf program. Golfers can enjoy exclusive perks such as priority disembarkation and embarkation, private transfers to and from the golf courses, equipment storage, and insurance. This ensures that golfers can focus on their game while enjoying the beauty of the Mediterranean.

With Costa Cruises, golfers can combine their passion for golf with a luxurious Mediterranean vacation, creating an unforgettable experience.

Birdie and Eagle Packages: Exquisite Golf Experiences

I can choose between the Birdie and Eagle packages to have an exquisite golf experience during my Costa Cruises vacation.

Costa Cruises offers a wide selection of golf courses for guests to enjoy. With the Birdie package, I will have access to three courses during my cruise. This package includes exclusive amenities such as priority disembarkation and embarkation, equipment storage and insurance, and a welcome kit in my cabin. I will also receive a snack basket, private transfers to and from the golf courses, and a golf kit. Additionally, I will have early breakfast times, the choice of dinner time, reserved seating in the restaurant, and special onboard offers.

For those looking for more golfing opportunities, the Eagle package offers access to four courses during the cruise, with similar exclusive amenities.

With these packages, I can have a truly exceptional golf experience while enjoying all the benefits of a Costa Cruises vacation.

How Long Has Costa Cruises Been a Sponsor of the Ryder Cup?

Costa Cruises has been a sponsor of the Ryder Cup for several years. Through this partnership, they offer golfers exclusive benefits such as access to multiple courses, priority embarkation, equipment storage, and more.

What Are the Specific Dates of the 2023 Ryder Cup Tournament?

The specific dates of the 2023 Ryder Cup tournament are not provided in the given context.

How Many International Courses Are Included in the Cruise & Golf Program?

There are 15 international golf course options included in Costa Cruises’ Cruise & Golf program. It’s a great opportunity to play different courses every day and explore various international golf destinations.

Can Golfers Play the Same Course Multiple Times During Their Cruise?

Yes, golfers can play different courses every day during their Costa Cruises golfing itinerary. There are multiple international courses available, providing golf course availability and the opportunity to explore various destinations.

How Many Golf Courses Are Available in Rome for Costa Cruises Guests?

There are multiple golf course options in Rome for Costa Cruises guests. They can choose from five courses in Rome and also have the opportunity to play courses in other destinations like France and Spain.

Affiliate disclaimer

As an affiliate, we may earn a commission from qualifying purchases. We get commissions for purchases made through links on this website from Amazon and other third parties.

Revolutionary Cruise Line Earns Forbes Travel Guide Award

Norwegian Pearl: Revitalized With Shipwide Upgrades

Princess Cruises Introduces Enhanced Premier Drink Package

Restart Plans And Health Protocols For Celebrity Cruises

Princess Cruises Cancels Extensive 2020 Sailings Amidst Covid-19

Which Celebrity Cruise Ships Have Been Refurbished

What Drinks Can You Bring On Princess Cruise

How To Turn On Cruise Control Tesla Model 3

What Is The Weather Like On A Transatlantic Cruise In April

How To Set Cruise Control Tesla Model Y

Ultimate Adventure and Relaxation Guide at Playa Mia Grand Beach Park

What Makes Sharkbanz Your Ultimate Fearless Travel Protection?

Enchanting Destinations in Vietnam: Exploring Hoi Hanoi Halong Bay

Exploring Juneau: History Wilderness Local Delights Uncovered

Azamara Onward: Origins, Renovation, and Future Plans

How To Check Weather For A Cruise

How To Get From Venice To Chioggia Cruise Terminal

How Do You Qualify For An Ultra Cruise On Carnival

Cruise is going to start charging for rides. Meet the 9 engineers from GM's self-driving bringing the first robotaxi service to the masses.

- Cruise's engineering team survived a time of uncertainty with a "resilience mindset."

- The self-driving startup hopes to pounce on an $8 trillion market for AVs.

- Cruise launched the first fully driverless ride in San Francisco earlier this year.

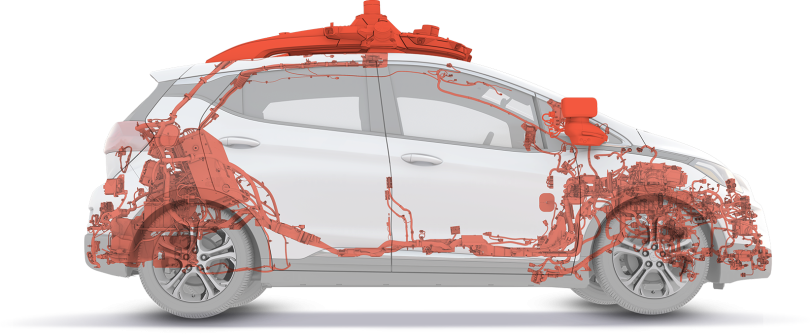

Cruise , the self-driving startup owned by General Motors , will be the first driverless taxi provider to charge a rare for its rides, propelling forward its plans to offer driverless taxi rides to the masses while many of its competitors have either moved away from driverless cars or pivoted to more commercial applications like trucking.

At the start of this year, Cruise began piloting fully driverless taxis — without a safety driver behind the wheel — in a major urban environment for members of the public. After about four months of a nighttime pilot program on the streets of San Francisco, Cruise in June won approval from the California Public Utilities Commission to charge for its driverless rides.

The company is offering driverless rides in western San Francisco through the app its product-engineering team built. Cruise is currently using its Chevrolet Bolt-based autonomous vehicles; the Cruise Origin, the startup's first AV built from the ground up, remains in development.

The team behind this achievement has been working quietly for the past several years as investors and other engineers lost hope in self-driving technology. A pedestrian death in 2018 caused by an Uber vehicle in self-driving mode spooked many investors and brought a new level of scrutiny to the space.

In this period, many startups ran out of money and hit the wall on technological development, thinning a herd of self-driving players that once powered the automotive industry's hype machine. With competition cut down, Cruise is hoping it can pounce on what its leaders say is an $8 trillion market waiting in the robotaxi and driverless-delivery space.

"One of the biggest shifts for us in the last few years is to have this resilience mindset," Mo Elshenawy, Cruise's executive vice president of engineering, said.

Elshenawy said it was important to be honest with his team about challenges and roadblocks while creating an environment where engineers can "embrace failure." He wanted his engineers to take risks without losing sight of the larger mission to safely put driverless cars on the road.

The quality of talent that startups attract is a major contributing factor in leading the autonomous-vehicle space, according to automotive-industry experts. In the past several years, Cruise has grown its team from around 40 employees, when GM acquired it in 2016, to 1,800 at the start of this year.

Here are the nine power players at Cruise leading the startup's charge to bring driverless rides to the masses.

Mo Elshenawy, executive vice president of engineering

Elshenawy heads the biggest team at Cruise and oversees the work of some 1,700 engineers tasked with developing every aspect of self-driving tech. The expertise on his team ranges from AI, robotics, and product engineering to mapping, safety, and hardware.

This diverse team of engineers recently celebrated the launch of Cruise's pilot driverless-ride service in San Francisco, a major win for a group that had worked tirelessly for years, Elshenawy said.

"There's only so much inspiration you can pump into your team yourself," Elshenawy said. "It's very different when you can get into this car at the end of the day and see all of your hard work."

Prior to Cruise, Elshenawy led global technologies for Amazon's ReCommerce platform, warehouse deals, and liquidations. He has also served as cofounder and CTO for three tech startups, including a cloud-based financial-services-development platform that top financial institutions use.

Tim Piastrelli, vice president of security

A strong web of product security, information technology, and threat detection and response are the keys to Cruise's plans to manufacture a purpose-built autonomous vehicle. Piastrelli and his team are constantly securing Cruise's technology via a battery of tests and simulations designed to identify potential attacks and sources of vulnerability.

With 15 years of experience in the field, Piastrelli said he was able to assemble a dream team of sorts for Cruise's security division that includes the hackers who remotely hijacked a Jeep Cherokee in a 2015 viral video for Wired.

"My primary focus initially was to pull in a few of the rock stars from my network," Piastrelli said. "As I built my specific threat models, I was able to articulate to leadership what specific people we needed to hire."

Before joining Cruise, Piastrelli headed security research at the software startup Mulesoft, where he also helped it complete its IPO.

Cristina Scheau, director of perception

Cruise's perception team builds the technology that "sees" the road and other obstacles around a self-driving car. As leader of the perception team, Scheau has overseen millions of miles in real-world and simulation testing to improve the way Cruise's vehicles navigate the streets of San Francisco.

Scheau joined Cruise two years ago, and since then she has spent much of her time recruiting and retaining talent in the areas of applied science, research, and engineering. Before joining Cruise, Scheau was the director of engineering at Facebook.

Wei Luo, vice president of strategy, product, and operations

Luo is an executive focused on the big picture for Cruise as it moves closer to commercialization. Some of her work includes collaborating with leadership to set clear long-term goals for scaling and expanding the business while helping teams across the company work efficiently to meet those marks.

Luo oversees several departments within Cruise, including the teams tasked with some of the company's most critical programs: ride-hailing, delivery, and vehicle-build programs.

Prior to Cruise, Luo served as COO of DeepMap, a software company, where she worked on the self-driving-mapping company's go-to market strategy.

Bhavini Soneji, vice president of product engineering

Soneji oversees work on Cruise's two main products: the ride-hailing app and the driverless fleet. She drives the strategy and execution for these two customer-facing products while also leading a team that is building the mapping platforms to guide the robotaxis on the road.

Prior to Cruise, Soneji was the vice president of engineering and technology at Headspace, a therapy app, and led teams at Heal, Snapchat, and Microsoft.

Hussein Mehanna, vice president of AI and machine learning

Cruise has spent years amassing millions of miles of on-road and simulated testing for its driverless cars. Mehanna leads the team that leverages the datasets from those tests to build artificial-intelligence models that can teach Cruise's fleet how to drive more like a human on unpredictable urban roads.

Prior to joining Cruise in 2019, Mehanna worked as an engineer with some of the biggest names in tech, including Google, Facebook, and Microsoft.

Vinoj Kumar, vice president of infrastructure

Kumar leads the team working on the infrastructure that underpins Cruise's entire fleet of autonomous vehicles. Kumar and his engineers have taken a "cloud-native" approach to Cruise's tech infrastructure, which means that the software has been designed for use in the cloud from the very beginning of development.

Kumar spent a decade at Google working in technical infrastructure before joining Cruise last year.

Rob Flenniken, senior director of engineering and embedded systems

Flenniken is one of the newest members of the Cruise engineering team, joining last month to lead the embedded-software engineering work the Cruise robotics team performs. Flenniken oversees a team working closely with hardware engineers to design and build the sensors, networks, and computer platforms that power the Cruise fleet.

Flenniken came to Cruise in April 2022 with more than 20 years of experience in the consumer-electronics industry, most recently at Amazon, where he led device-software teams to build the first Alexa device, the Echo.

Louise Zhang, vice president of safety and systems

With Cruise beginning to offer rides to the masses, Zhang has the critical task of overseeing safety and validation of the startup's driverless fleet. She has an instrumental role in every phase of development for Cruise's vehicles from design to testing to commercial deployment.

Zhang's team is working on both future and current Cruise vehicles, validating autonomous-driving systems and developing operations-safety guardrails for deployment.

Zhang came to Cruise in 2020 with a strong background in vehicle safety. She was previously the senior director of engineering at Lucid Motors, an EV startup, where she oversaw vehicle safety and regulatory compliance. Prior to that, Zhang was head of Tesla's safety team.

- Main content

Cruise Engineers Balance Safety With Experimentation in the Pursuit of Autonomous Vehicles

On the surface, the concept of a self-driving car seems deceptively simple. But after a decade of splashy announcements and enormous investments from Silicon Valley’s most influential organizations, few people understand the dichotomy between the idea and its execution better than Mohamed Elshenawy. As senior vice president of engineering teams at autonomous vehicle company Cruise, he spends his working life neck-deep in the challenges that come from building a self-driving car.

“One of the common questions I get asked by friends and family is, ‘Why does it take so long to solve the self-driving problem?’”

The answer?

“We aren’t teaching a human brain, which has already evolved over hundreds of thousands of years to accurately perceive the world and predict actions within their surroundings. We are essentially building an AV brain that can do all that without stagnating or making silly mistakes or getting tired, bored or distracted. In order to do that, we’re compressing hundreds of thousands of years of human intelligence into just a few years.”

Cruise Background

While some self-driving contenders have opted to test their technology on quieter roads in the hopes of solving “easier” driving conditions before venturing into complex urban driving, Cruise has jumped straight into the deep end — in this case, the hilly streets of its hometown. The theory goes that once you’ve solved city driving — with its construction sites, pedestrians, cyclists and haphazard traffic — it will be easier to scale out and expand the service elsewhere.

To support its engineering work, Cruise has organized its teams around the concept of psychological safety.

“We have to be willing to embrace risks within our safety bounds, different perspectives and new ways of doing things,” Elshenawy explained. “This experimentation mindset is part of a new paradigm shift we’re seeing toward ML-native companies, ones that are not just optimized by ML but defined by it.”

To learn more about the organizational architecture that provides space for innovation within its strict safety standards, Built In asked Elshenawy to explain what psychological safety means in practice.

Why is psychological safety especially important for an autonomous vehicle company like Cruise?

We are trying to do something that’s never been done before, and that inherently means this is an applied experiment in many ways. Psychological safety allows us to rewrite how we think about failure and makes room for innovation and individual growth — something that is core to Cruise’s value proposition — allowing people to unlock their full potential, speak up, raise flags without fear, effectively experiment, take on calculated risks and, ultimately, improve.

Taking a calculated risk that doesn’t pan out or having to pivot a project because it’s not yielding the results you were looking for is not a failure; it’s an opportunity to learn. The reality is we should have more “failed” experiments than successful ones, and my leadership team and I are committed to providing the psychologically safe environment and feedback mechanisms necessary to learn fast and fail forward, emerging from each experiment with valuable lessons that lead us to our next big win. As we continue to grow, I hope this culture of experimentation and innovation helps us maintain a startup spirit.

How does your organizational structure reflect and reinforce Cruise’s emphasis on psychological safety?

The organization is based on principles of continuous improvement, autonomy, simplicity and respect in order to facilitate growth, development and innovation for every individual and the team as a whole. My ultimate goal is to foster an innovation and learning mindset within my team, based on an organizational structure that is nimble enough to support effective experimentation yet disciplined in mapping against our goals.

Psychological safety is at the root of this. Every member of our team needs to feel empowered to experiment, speak up, ask for help or feedback and make bold moves within our safety guidelines. Vertical integration of teams and tools across the organization form functional units within groups that make iteration and quick innovation more seamless. We’ve also been deliberate in keeping the organization flat in order to allow information and decisions to travel faster in both directions, including why certain decisions were made in the first place. Not only does this give us the agility and speed to achieve our mission, but it also creates a respectful and inclusive culture. A great example of this is our quarterly planning and review sessions, which are open to all team members as well as shared externally to the company in order to ensure alignment, make sure voices are heard and provide folks with an opportunity to influence how we, as a team, operate.

What’s an example of psychological safety in action?

Beyond fostering a more productive working environment, psychological safety also quite literally translates into our on-road safety and performance. At the foundation of our iterative release process are mechanisms for feedback and reporting, reviewing and addressing risks at every level.

A common thread for safety failures in any company is that knowledge of the safety problem existed, but it wasn’t adequately communicated to the right people, with the right detail or action plan. We have designed a system, within our release cycle and across the company as a whole, that seeks to ensure there are no gaps in our identification and communication of safety risks, and that all identified risks are addressed at the right level with input from those with the greatest understanding of the specific issues.

The goal is to empower every person with knowledge of a safety risk to raise it effectively, to triage those risks efficiently and to address them promptly at the right level with the best possible information.

“ It’s easy to view those safety parameters and requirements as limiting factors, but I’ve found the opposite to be true. It has pushed us to be more creative and rethink the conventional development process.”

Most companies would claim that they encourage ambitious projects and innovation. What sets Cruise apart in this regard?

AV is not a science project relegated to a lab — it’s real and it’s interacting with people and other drivers on the streets every day. This sets the performance and safety bar incredibly high and it’s something we take very seriously.

We have to balance cutting-edge innovation without ever compromising safety. It’s easy to view those safety parameters and requirements as limiting factors, but I’ve found the opposite to be true. It has pushed us to be more creative and rethink the conventional development process.

We have also invested heavily in end-to-end tooling that integrates to form an AI and robotics platform which is key to increasing our iteration speed. This includes homegrown tools such as Webviz, our open-sourced platform for robotics data visualization, and our continuous learning machine, a framework for self-supervised auto-labeling data and active learning data mining. These tools, paired with a unique CI/CD process, feedback loops that connect our simulation with real-world performance, and our powerful, scalable infrastructure, allow our engineers to understand their impact on on-road performance. At the same time, they can safely go from ideation to production in days.

Great Companies Need Great People. That's Where We Come In.

The only cruise blog for the Middle East and South Africa

The key milestones during a new cruise ship’s construction

From steel cutting and coin ceremonies to float outs and deliveries, what are the key stages involved in a new cruise ship’s construction?

MSC Seashore under construction for MSC Cruises

RELATED: Industry: How do you build the first go-kart race track at sea?

RELATED: Industry: What the media get wrong about cruises and bad weather

There are currently more cruise ships on order than at any other time in the cruise industry’s history, with more than 20 being delivered every year from 2020 onwards, but what are the key milestones and stages to a cruise ship’s build process?

First – Initial Order

Cruise lines place an order for a cruise ship, or more usually a series of new cruise ships in a new class, with one of the world’s primary cruise ship-building shipyards. The Finnish-French STX Europe, Germany’s Meyer Werft and the Italian shipyard Fincantieri are the global leaders in cruise ship construction.

Because of the limited number of specialist cruise shipyards, and the huge number of cruise ships being built, these shipyards have vessels in varying stages of construction at any one time. Some are in the steel cutting phase, others are about to be floated out, while others are undergoing final fit out and finish.

When cruise line’s place their order, there will be a confirmed order for a set number, usually one or two, and an ‘option’ for several more, which can be exercised or cancelled at the cruise line’s discretion, depending on market conditions and the success of the initial model.

No name or details are given about the ship at this stage, just the gross tonnage, possible class of ship (for example a sister ship or a brand new design) and usually the passenger capacity. Delivery is usually scheduled for three to four years.

Second – Steel-Cutting

At or just before the steel cutting ceremony the name of the ship will usually be revealed. Modern cruise ships are built in sections, each of which are made up of thousands of individually-cut pieces of steel forming the hull, bulkheads and decks.

Seabourn and shipyard executives initiate steel cutting for Seabourn Venture

RELATED: Celebrity Cruises cuts steel for third Edge-class cruise ship Celebrity Beyond

RELATED: Cunard Line begins build of its new unnamed cruise ship with first steel cutting

The first of these pieces of steel are cut in front of senior management from the cruise line and the shipyard, as well as members of the press and local dignitaries, such as the mayor or local member of parliament.

An executive from the shipyard and the cruise line will sometimes push a button together to start up the steel cutting machine.

The process of steel cutting then continues for several months in order to produce the many thousands of individual pieces of steel required for the ship, which are then welded together to form the individual sections or blocks.

Third – Laying the Keel

The first of these blocks will form the ship’s keel, or part of it. Ships back in the day were traditionally built from the keel up, it was riveted together along the length of the construction dry dock, and then the hull support structured were added to it like ribs. The steel plates of the hull would then be riveted to the keel.

Nowadays, however, there is no real keel, so the keel laying ceremony is more of a first block laying ceremony. This first block is lowered by crane into the construction dry dock with exact precision, usually using GPS coordinates and lasers to provide pin-point accuracy.

Wonder of the Seas’ keel is laid in France

RELATED: MSC Cruises lays keel for new Middle East-bound mega-ship MSC World Europa

RELATED: Seabourn reveals unique Bow Lounge for new Seabourn Venture after keel laying

This is the beginning of an ongoing process whereby sections of the ship will be built in other parts of the shipyard, or indeed the world, and then transported to the construction dry dock where they are dropped into place and welded together.

These huge blocks weigh upwards of 150 tons, sometimes double that for a large 100,000-plus gross ton ship and although they contain all of the wiring and plumbing required for the ship, they’re usually just bare steel on the inside, because interior fit out happens later.

As the ship progresses toward the float out stage, the azipods will be fitted (all the engineering required is already pre-built into the engine room blocks) and she will be made fully waterproof.

Rotterdam’s godmother with the coins welded to the ship’s hull

The Coin Ceremony Although not a specific stage in the cruise ship’s construction, the coin ceremony is usually held at or soon after the keel laying. Specially commissioned gold coins are laid in the keel block to symbolise good luck – they can be welded in place or just placed in the block and then retrieved later on to be welded into the base of the navigation mast in a ‘mast stepping ceremony’. For the coin ceremony there will a separate Godmother (Madrina) , who is a different person to the official Godmother that will name the ship.

Fourth – Float Out

The float out is the first of the really big milestones (followed by the delivery and christening). By this point in the build, the ship’s exterior is all but finished and work is in high gear to complete the interior, with the public rooms being built and the prefabricated cabins being installed. They’re installed in a turn-key state, with just the piping and wires needing to be connected, and the soft furnishings added.

Valiant Lady of Virgin Voyages following her float out at Fincantieri

Cruise line and shipyard executives, members of the press and local dignitaries once more gather and the ship’s construction dry dock is filled with water. The godmother from the coin ceremony might smash a bottle of water against the bow and then the ship is towed by tugboats to the fitting out pier. The first bit of water to touch the ship’s keel might also be collected and presented to the captain of the vessel.

The final fit out and finish takes month and it’s during this process as well that her engines will be brought online for the first time and tested ahead of the departure of the ship on her sea trials.

Fifth – Sea Trials

Once all of the ship’s engineering systems and thousands of items of equipment have been brought online, she will be ready to undertake sea trials, during which all of these many systems will be tested in real world conditions for the first time.

The ship isn’t complete yet, various sections of her exterior might still be under construction, but all the engineering is ready. The trials could last several days and may be undertaken in several stages if it is a completely new class of ship, built to an entirely new design.

Carnival Cruise Line’s new ship Mardi Gras departs on her sea trials from Meyer Werft

RELATED: Video: New Carnival Cruise Line mega ship Mardi Gras completes sea trials

RELATED: Newly-lengthened Star Breeze 1st of 3 stretched ships to depart for sea trials

Crew, shipyard workers, contractors, insurance representatives and officials from the ship’s flag state and classification society will all be onboard for these sea trials to certify that she is ready to be delivered. Tests such as crash stops, high speed turns, and other maneuvers are performed to make sure everything works as intended.

If no major problems are found, she will return to the fitting out pier and work will continue on the interior and superstructure. Sometimes ships will go back into dry dock if engineering issues are discovered that require her to be removed from the water.

Sixth – Delivery

A few weeks or months later the ship is officially delivered to the cruise line in a hand over ceremony that marks the transfer of ownership. Executives from the shipyard and cruise lines, along with the press and local officials assemble and the shipyard’s flag is lowered, to be replaced by the cruise line’s colours.

At this point, the ship is all but complete, but still requires her full crew complement and all the stores and supplies required for operation. These will usually be taken onboard at the first homeport from which the ship will sail its inaugural cruise season, or at the port where the christening or naming ceremony takes place.

Seventh – Shakedown Voyage

The shakedown voyage is like a second set of sea trials, except with a full crew complement and usually a few pretend passengers made up of cruise line staff, media and contractors to test the ability of the ship to operate as a cruise ship.

It lasts a week or so and will also see the finishing touches to the ship being made by shipyard staff and external contractors. All the crew will also be trained in how to work aboard the new ship, going over cruise line protocols and emergency training.

Marketing staff will also be onboard to take pictures and videos of the ship while everything is brand new and free of passengers.

Eighth – Inaugural Voyage

Not all cruise lines sail an inaugural voyage as the shakedown cruise is sometimes combined with the inaugural voyage, which usually involved the cruise ship sailing from the nearest port to the shipyard to the port at which she will be christened and depart on her first revenue-generating cruise.

This gives the cruise line another chance to test the crew’s readiness to serve a full complement of guests, and passengers are usually drawn from the cruise line’s shoreside staff, travel agents and media.

Ninth – Christening

This is the final big milestone in the ship’s construction. At her first homeport, or the port from which she will depart on her first revenue-generating voyage (the maiden voyage), a party is held with representatives from the cruise line, shipyard, cruise industry and the media all in attendance.

Fireworks mark the christening of MSC Seaview

RELATED: Princess Cruises christens new ship Sky Princess after taking delivery from Fincantieri

RELATED: Spirit of Adventure completes Ems conveyance ahead of delivery to Saga and christening

During this ceremony the ship’s official Godmother, usually royalty, a celebrity or someone celebrated for their contribution to the community, will name the ship, bless her and smash a bottle of champagne across the bow. By tradition, the champagne would be swung against the hull from a rope, but its considered bad luck if the bottle doesn’t break so nowadays cruise line’s use a hydraulic arm to ensure that it does.

Tenth – Maiden Voyage

After the christening, the ship departs for the first time with paying passengers. For a cruise ship built in Europe, but destined to serve the North American market, this is usually a trans-Atlantic repositioning cruise, or a grand voyage to Asia via the Middle East and Dubai, such as was the case with Quantum of the Seas and Spectrum of the Seas.

From this point on the ship will be in cruise operation as much as is possible for the next five years, until she goes into dry dock for her first full hull inspection. During this dry dock period the carpets and bedding might be replaced, or some public rooms, such as bars and restaurants might be reconfigured based on passenger feedback.

Share this:

- Click to share on Twitter (Opens in new window)

- Click to share on Facebook (Opens in new window)

Categories: Cruise Features , Cruise Industry

Tagged as: cruise ship construction , float out , new cruise ship , shipyard , steel cutting

Published by Shaun Ebelthite

Founder and editor of Cruise Arabia & Africa. I try to create the best news and information specifically for cruise passengers taking cruises to and from Dubai (where I live) and South Africa (where I was born). You can contact me at shaun(at)cruisearabiaonline.com. View all posts by Shaun Ebelthite

1 reply »

Great article, very informative! I enjoy this blog very much, I’m an ocean liner enthusiastic in Illinois for more than 10 years.

Leave a Reply Cancel reply

Get in touch.

Email : shaun(at)cruise-arabia.com

Discover more from

Subscribe now to keep reading and get access to the full archive.

Type your email…

Continue reading

Building continuous integration & continuous delivery for autonomous vehicles on Google Cloud

Mo Elshenawy

Executive Vice President of Engineering, Cruise

Anchoring on Containers

Learn why Google Cloud’s container offerings lead the market

San Francisco’s roads are a notoriously tough place for people to drive. Narrow streets, busy pedestrian traffic, and an extensive network of bicycle routes make driving through San Francisco roughly 40 times more complex than driving in a suburban environment, according to Cruise data. This level of complexity makes San Francisco, America’s second densest city, an ideal environment for testing the most advanced self-driving technology found in today’s autonomous vehicles (AVs).

Cruise has been focused on tackling city driving since 2013, and with more than 3 million autonomous miles under our belt, we are getting close to delivering an all-electric, shared, self-driving service. In January 2022 we reached a major milestone — members of the public took their first fully driverless rides in San Francisco.

Developing an urban fleet of fully autonomous vehicles is an incredible challenge. To be successful, we needed to build both the AV tech that’s out on the road and the ecosystem of tools our engineers use internally.

In creating this cycle, we thought carefully about how to best empower our engineers. Home-grown technology chains like this can get unwieldy quickly — the last thing you want as an engineer is to fight the disparate tools you are using or jump across too many of them to get your daily work done. Google Cloud has been a useful tool for us as we worked to streamline and support this development cycle, adapt our cloud-first infrastructure strategy, and seamlessly scale our systems. The frameworks we use in the vehicle, data logging, visualization, data mining, and ML modeling are all built on top of a common foundation that makes going from road to code — and from code to road — fast and safe.

Let’s take a deeper look at how Google Cloud supports the pillars of our homegrown AV development cycle.

The foundational platform

At the base of this development cycle is a strong foundation of Google Kubernetes Engine (GKE) and Compute Engine virtual machines (VMs) with other Google Cloud Infrastructure Services such as Cloud Storage, CloudSQL, PubSub, Cloud Functions, BigQuery, App Engine, and Cloud Logging and Monitoring, etc. We chose to use Kubernetes (k8s) to build our multi-tenant, multi environment Platform as a Service, and build a homegrown tool we call “Juno” that helps Cruise application developers to iterate and deploy at scale instantaneously.

On this Kubernetes and Istio-based Service platform (PaaS) we reuse a set of Kubernetes (k8s) operators/controllers to manage k8s clusters, manage nodepool migrations, and inject default add-ons for monitoring, logging, and service mesh. Under the hood we reuse Google Cloud’s Config Connector to manage dependencies while creating k8s resources. We run containerized workloads namespaced for multi-tenancy with high compute utilization and less operational overhead. We choose to isolate k8s clusters on the Service platform across development, staging, and production environments. We have also standardized continuous integration and continuous delivery to each of these environments.

At the infrastructure level, we configured Google Cloud with vertical and horizontal boundaries. These boundaries and permissions, including Kubernetes namespace RBAC, Google Cloud projects and Google groups are managed centrally with our homegrown resource lifecycle manager, PaaS Juno.

Vertically, we use Google Cloud folders and projects to separate each team’s development, staging, and production environments from other teams’. These environments each have their own VPC, subnets, firewalls, interconnects, NAT gateways, private DNS, and any other Google Cloud service that the application service may need, for example GKE/k8s, Compute Engine, Cloud Storage, Pub/Sub, etc. The services are connected by a network, but traffic between them can be easily audited and regulated.

Horizontally, Google Cloud projects within each environment allow for distinct permission management and visibility constraints between tenants. Projects make it easy for tenants to focus on what matters to them. Separation between tenants makes it harder for malicious actors to gain unauthorized access, and prevents tenants from accidentally impacting one another.

The ML Brain: ingestion, analysis and modeling

With this strong foundation in place, we’re able to start feeding the pipeline. Every day, we traverse San Francisco’s city streets and collect a lot of anonymized road data.

At a high level, we take all sensor data as input — from camera, lidar, audio to radar. From there, Cloud Storage and Dataflow help us create highly scalable ETL pipelines and data lakes to create and extract petabytes of on-the-road data quickly and efficiently. Leveraging BigQuery, few hundred engineers are able to process exabytes of data across more than 20 million queries every month .

But even in San Francisco, less than 1% of the raw data contains useful information, and we quickly realized that we would need to distinguish the signal from the noise to make this work. At our scale, automation was the only answer, so we invested heavily in automatic AI-based event extraction and classification. Using advanced AI for scene understanding, today we can automatically label and tag many different classes of events, and then make them immediately available to every engineer. For example, we rely on panoptic segmentation to recognize trash bins and other objects along the side of the road; we use fine-grained classification to distinguish emergency vehicles from other cars; and we track objects across time and sensors to estimate their motions.

After we ingest and analyze that data, it’s fed back into our dynamic ML Brain — a continuous learning machine that actively mines from the collected data to automatically train new models that exceed the performance of the older models. This is done with the help of Vertex AI , where we are able to train hundreds of models simultaneously, using hundreds of GPU years every month!

Together, the automation, data sharing, and collaboration that Google Cloud’s tools provide supercharge Cruise engineers’ daily work.

Testing and simulation: Building an AV “time machine”

In addition to powering the ML Brain of the fleet, we also leverage our Google Cloud infrastructure to test/validate at scale, and build the confidence we need in order to release multiple times per week.

No matter how many miles our fleet racks up on the road, there will always be unexpected moments that we won’t capture with road miles alone—we need to couple road data with robust simulation data to ensure a safe and comfortable ride for future customers.

To make this happen, we developed a highly complex, distributed suite of testing and simulation tools that work in concert on top of Compute Engine .

First, we rely on a tool we call “Morpheus” to generate specific testing scenarios quickly. Simulations are a scalable way to perform robust testing around rare and difficult events at any time of day, in any condition, and in any location. Need to test an AV driving down a misty one-way road at twilight? Or see what it’s like to crest a steep hill while driving east at sunrise? What about a rush-hour evening drive along the Embarcadero on game day? Morpheus automatically creates a realistic real world to “drive” through to maintain Cruise’s rigorous safety standards.

To populate that world with unique driving scenarios we developed a tool called “Road-to-Sim” which fuses information from our millions of real-world miles to create a full-simulation environment from road data. This is an automated conversion pipeline that procedurally recreates any on-road event without manual intervention. This lets us easily create permutations of the event and change attributes like vehicle and pedestrian types.

Simulation helps us prepare for geographic scale as well. We developed “WorldGen”, a system that can procedurally generate entire cities, allowing us to test in new operational design domains more efficiently and with a shorter lead time. By combining multiple sources of data, we build seamless map tiles across large geographic areas that can immediately be used for large-scale testing.

At the root of this robust simulation engine is “Hydra”, our homegrown batch scheduling platform that scales up to tens of thousands of custom VMs that are optimized using Google Cloud's custom instances to run millions of simulations every day.

While Hydra is a batch servicer, we have many types of batch workloads like simulation, ground truth labeling, and remote builds. All in all, Google Cloud’s highly elastic platform allows us to easily consume 10s of GPU years per day and 1000s of core years per day. In return, our simulation engine generates petabytes of synthetic data daily, which then is parsed, analyzed and fed back into our development cycle.

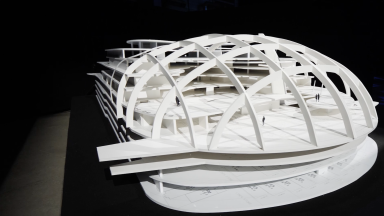

This robust simulation and testing engine not only helps us scale and improve our current fleet of AVs, it also gives us a head start in testing and validating our next-generation vehicle: the Origin . Before the Origin ever hits the road, it will have been driving in simulation for years beforehand, encountering and learning from countless long-tail events in the cloud.

Ensuring resilience amidst uncertainty