Register to access Secure Tools, Applications and Reports to help simplify your business.

Union Pacific

Emergencies:

- UP Emergencies: 1-888-877-7267

- Communities

- MyUPRR Customer Sign In

Emergencies: 1-888-877-7267

- Announcements

- Customer News

General Announcements

Status of the railroad - a message from kenny rocker, evp, marketing & sales.

Announcement Number: CN2020-65 Categories: General Announcements Posted Date: December 21, 2020

- Freight Car Velocity (daily miles per rail car) – Car velocity was at 225, improving 1% from a year ago, making November one of our best months in 2020.

- Freight Car Terminal Dwell (the amount of time a rail car spends in a Union Pacific rail terminal/yard) – Dwell times are down to 22.2 hours, improving 3% compared to this time last year and lower than any month in 2019.

- Car Trip Plan Compliance (on-time shipment delivery) – Manifest/auto trip plan compliance improved by three percentage points to 74% compared to a year ago, while intermodal trip plan compliance was 82%, down one percentage point from 2019.

Section Menu

- Go to RailPrime »

- Branded Features

- Past Features

- Contributed Content

- Find Content By Keywords

- Short Lines and Regionals

- Passenger Rail

- Legislative & Reg.

- Rail Industry Trends

- Supplier Spotlight

- High Speed Rail

- Internet/Digital

- Sustainability

- Canadian National

- Canadian Pacific

- Canadian Pacific Kansas City

- Kansas City Southern

- Norfolk Southern

- Union Pacific

- All current Rail Industry Jobs

- Digital Demos

- 2021 Readers Choice Award Winners

- Featured Products

- Railway Interchange 2017 Product News

- Rail RFP Notices

- Buyers' Guide: Rail Components & Services

- Freight Cars

- Freight Car Products

- Passenger Cars

- Passenger Car Products

- Locomotives

- Locomotive Products

- Track Components

- C&S Components

- Car & Locomotive Manufacturers Reps

- Track Manufacturers Reps

- Car Repair Services

- Locomotive Repair Services

- Contract Services

- Consulting Services

- Special Reports

- Rail Industry Events

- Upcoming Conference Sessions

- Rising Stars

- Railway Interchange 2017 Updates

- Read Current Issue

- Print Subscription

- Car and Locomotive

- Manufacturer Alphabetical Listings

- Purchase Yearbooks

- Manage Your Yearbook Listing

- Advertising

- Email Management

- Print Magazine

- Content Usage

- Media Resources

- Browse Keywords

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

- BNSF/KCS marketing alliance nurtures Class Is' recent affiliations (4/23/2002)

- Superintendent

- Short Lines & Regionals

October 2020

CSX counts on more acute customer data, engagement to cut deeper into truck's share

By Jeff Stagl , Managing Editor

When Mark Wallace joined CSX in spring 2017 as executive vice president of corporate affairs and chief of staff, the Class I was preparing to embark on a massive operational overhaul through precision scheduled railroading (PSR). An effort he once characterized as “scheduled railroading on steroids,” PSR has vastly improved CSX’s fluidity and service performance.

But after Wallace became the Class I’s EVP of sales and marketing in July 2018, he discovered another aspect of the company that needed a makeover: the commercial organization. A longtime Class I senior management executive who spent 20 years at CN and Canadian Pacific prior to joining CSX, Wallace determined the sales and marketing department needed retooling to spur more growth.

“It was apparent to me that we had a good team, but there was a lack of data and analytics, and a business marketing focus. Marketing was essentially a pricing department,” he says.

Since PSR changed the course of CSX’s performance to a much more consistent and reliable service offering — perhaps the best among the Class Is instead of what had been the worst — the department should be better positioned to exploit that advantage, Wallace concluded.

As measured by trip plan compliance (TPC) — or the success in meeting end-to-end customer commitments based on estimated times of arrival — service performance is registering percentages in the mid-70s for carload movements and mid-80s for intermodal traffic. Several years ago, those percentages likely would have been in the 50s and 60s if measured the same way (CSX created TPC while implementing PSR).

Wallace‘s changes included staffing the sales and marketing department management team with professionals who had advertising, finance, Wall Street or other backgrounds instead of strictly rail industry experience to broaden the organization’s institutional knowledge and alter its approach.

For example, in March 2019 Kevin Boone — a senior equity research analyst at Janus Capital who covered the transportation sectors — was appointed VP of marketing and strategy to lead a newly created marketing team. And in October 2019, Farrukh Bezar became senior VP of marketing. He previously was a managing partner at Lynwood Partners, a transportation and logistics advisory firm he founded in 2017, and a financial analyst at Chase Manhattan Bank.

Wallace also aimed to refocus the department’s team by changing account managers’ title to sales managers to better motivate and engage that boots-on-the-ground staff, and pulling the customer service team from the operations department and renaming it the customer engagement team. The new name better suits the customer representatives since they are the company’s communicative link to shippers and receivers, says Wallace.

“They are more proactive now and don’t wait for the phone to ring,” he says.

To prompt bigger results in a proactive vein, Wallace sought to generate more useful data, analytics and business intelligence in the department. The commercial organization didn’t always have detailed information on where freight traffic flowed and why it was moved by certain modes, but such vital data is collected now, he says.

“Railroads had all this business 50 years ago, but trucks have taken it over since. Where is this freight? That’s the big opportunity for us,” Wallace says. “Now, we have good information on flows and if freight is going 200 or 500 miles, and why it moves by rail or truck. We were blind to that in the past.”

The data and analytics effort, which began in spring 2019 with an accelerated push, helps differentiate CSX from other railroads, says Bezar.

“There is no other railroad as focused on data and analytics on the commercial side as us. It’s ingrained in our DNA,” he says. “We can make better decisions faster.”

Trucks a moving target

Since CSX has only a sliver of North America’s $980 billion freight transportation market — a scant 1 percent — the railroad can seize a larger chunk by taking advantage of its footprint and fast transit times to divert more freight from highways, Wallace says.

The iron is hot for traffic diversions since truck rates are skyrocketing during the COVID-19 pandemic to as much as 15 percent higher than rail.

Extremely tight capacity and an alarming driver shortage are negatively impacting the trucking industry.

CSX now is afforded an opportunity to pursue freight in lanes it hasn’t traditionally registered much or any traffic in, says Wallace.

To seize it, sales managers are charged with sitting down with shippers — including those CSX lost the past few years or have never used rail — and reviewing their transportation usage. They discuss what the shipper spends on transportation per year, which lanes they use, and why they rely on certain modes, including trucks, or don’t use rail.

It’s all about convincing more shippers to try CSX or expand their business with the railroad, Wallace says. Since the Class I’s poor service performance of the past might still be an issue, sales managers can talk about the “new CSX” and what the railroad can do for them, he says.

“We realize customers are trying to save dollars now because of COVID. We can explain how we’re a different railroad than we were before we put in PSR in, and we can turn conversations around,” Wallace says.

It’s all about trying to better understand customers compared with efforts of the past and adjusting approaches based on how markets are changing, says Bezar.

“The behavior of the rail industry has historically been: ‘What can you do for me?’ That’s evolved now, and the focus is on adding value for a customer and doing things differently,” he says.

The challenges customers face in their supply chains previously had been underestimated by the sales force, says Arthur Adams, CSX’s VP of merchandise sales. [ Editor's note: On Oct. 19, CSX announced Adams had been promoted to SVP of sales. ]

“Now, we have an appetite to provide solutions that solve their pain points,” he says.

Relating to customer relations

Another way the sales and marketing team tries to better learn and solve shippers’ needs is through customer engagement forums. Once or twice a year, representatives from 30 to 40 customers are invited to CSX headquarters in Jacksonville, Florida, for several days to conduct talks with commercial executives in causal settings, such as dinners and chats in small groups. One such forum was conducted last month.

“We talk about how we’ve changed, listen to their concerns and gain their feedback,” says Wallace. “We want stickier relationships with customers.”

Building and retaining customers’ business means continuing to position CSX as a solutions architect, says Adams. That might mean creating a reload, resolving a first- or last-mile issue, or developing a warehousing or transloading solution.

“If we can add value, it bolsters a customer’s stickiness,” says Adams.

Partnering more with customers tends to add a lot of value for both parties. To that end, CSX last year partnered with A&R Logistics Inc. to build a warehouse in Charleston, South Carolina, for plastic resin exports. The 500,000-square foot, CSX Select Site warehouse — which eventually could expand to 1 million square feet — is slated to open in the fourth quarter.

The railroad will transport resins to the warehouse, where they will be bagged and then moved to the Port of Charleston for export.

“We will do more of these partnerships if they make sense and we have the capacity,” says Wallace.

In transload mode

Another partnering effort occurred in fall 2019, when the railroad worked with several metal customers to transform an idle CSX facility in East Chicago, Indiana, into a metal transload facility. The facility handles a variety of metals — with coils and ingots being the primary ones — and serves a variety of steel shippers.

The metal customers had planned on establishing such a facility in Illinois, but certain state taxation laws prevented that, says Adams. CSX also is in the early stages of creating a similar metals transload facility in the Ohio Valley.

Transloading is a key arrow in the railroad’s transportation-solutions quiver. The Class I’s TRANSFLO subsidiary can move bulk commodities from rail to truck or truck to rail, and currently manages more than 40 transload facilities and handles more than 300 bulk products.

In the fourth quarter, the Class I expects to open a CSX-operated transloading facility in Savannah, Georgia, for containerized food grade and agricultural products, including DDGs and oils. The intent is to target a broad swath of customers for the facility, which also will handle some freight headed to or from the Port of Savannah, says Adams.

Another business-building target: inland ports. CSX serves seven inland ports in Alabama, Georgia, Massachusetts, Ohio, New York and South Carolina.

Five of them have generated less than 80,000 units in 2020 through September, and the two in Ohio — which are privately owned and operated — currently aren’t moving any freight due to low demand.

“It’s boomtown USA with the amount of freight coming to eastern ports. Some customers like inland ports,” says

Wallace. “We have them in areas that are seeing rapid growth locally. It’s another way to take traffic from trucks.”

A good growth engine

Intermodal traffic as a whole offers a lot of promise for CSX. The Class I is registering volume strength across its intermodal business, which appears to be both a short- and long-term growth engine, says Wallace.

“We believe in that business,” he says. “It’s an e-commerce economy now with Amazon and all the online shopping because of COVID. We see strength because of replenishing inventories.”

Wallace also is confident the typical volume peaks will continue in the fall from retail sales generated by Halloween, Thanksgiving, Christmas and other drivers.

CSX serves 46 intermodal facilities in 17 states and two Canadian provinces, and operates 29 of them. The railroad moves intermodal traffic in more than 900 individual lanes after a recent rationalization trimmed unnecessary lanes, where freight traveled short distances but needed to be handled many times.

The Class I’s intermodal franchise will gain a boost next year when the Carolina Connector (CCX) intermodal facility opens near Rocky Mount, North Carolina.

The facility is being built in cooperation with the state of North Carolina and will serve the Raleigh/Durham/Greensboro metropolitan area, as well as other portions of the state and parts of Virginia.

The mixed-use domestic and international CCX facility will include an inland port connecting with the state’s Port of Wilmington and one yet-to-be-determined major East Coast port.

In the merchandise sector, CSX is registering volume growth with forest products and pulp board.

The pandemic has driven demand for Amazon boxes, diapers and toilet paper, which are produced from the pulp board, says Wallace. Other consumer goods — such as paint and plywood — are booming because of COVID-19, too, and driving merchandise carloads.

In addition, a good grain crop is on the way this fall, and petrochemical and chemical shipments are promising, says Wallace.

As traffic ticks up, CSX strives to continue measuring and tracking its service performance via the TPC tool, which provides shippers real-time access to a car in transit. The railroad is using its third iteration of the tool, which has been improved based on customer feedback.

The first-phase tool tracked intermodal traffic, the second incorporated merchandise carloads and the third expanded details on each car.

Shippers have reacted positively to TPC, particularly the transparency it provides on service reliability, CSX execs say. The railroad is the only Class I that publishes its schedule performance, they add.

Shippers also appreciate recent efforts to overhaul all customer-facing tools to make them more efficient, an outgrowth of CSX’s ongoing digital transformation, says Bezar.

Empowering employees

One other major transformation in the sales and marketing department involves the cultural kind. Wallace & Company have been trying to empower employees to better understand the organization’s priorities and to give them the autonomy to make decisions, be creative and take some risks if need be.

“We’re trying to be an agent of change,” says Bezar. “We encourage people to use their minds because continuing to get better is the goal, to strive to be the best in the industry. We seek tighter integration with customers.”

A simple thing such as the account managers’ title change helps reinvigorate the entrepreneurial spirit among employees, says Adams. The sales force then is better engaged to challenge a customer to think differently about their supply chain needs, he believes.

If CSX is going to reach its business-growth goals — especially during and after the pandemic — the sales and marketing revisions need to carry on. Although more needs to be done, there are signs that the railroad is making the right adjustments, says Adams.

“We are not declaring victory, but there is energy and excitement around what we are doing. It’s the art of the possible,” he says. “We will continue to look for new opportunities, provide the reliable service customers expect and continue out technological investments.”

Email questions or comments to [email protected] .

- © TradePress Media Group 1995–2024

- Email Management |

- Print Magazine |

- Advertise |

- Contact Us |

- Content Usage |

- Reprints |

- Policies |

- Contributed |

- Site Map

Other FreightWaves Products

- FreightWaves

- American Shipper

- Modern Shipper

- Ratings.com

- FreightWaves TV

- Newsletters

- FreightCasts

- Whitepapers

- Advertise with Us

- FreightWaves Ratings

- State of Freight Insights

- Global Supply Chain

- FreightWaves Classics

- Blockchain News & Updates

- Legal issues

- Sustainability

- Company Earnings

- Truck Driver Issues

- Trade and Compliance

- Shared Truckload

- Insurance & Risk Management

- Optimizing Fleet Compliance

- Recruiting Rundown

- Smarter Capacity

- Reinventing Freight Procurement

- Carrier Cyber Security

- Logistics/Supply Chains

- Freight All Kinds

- Trucking Regulation

- Last-Mile Delivery

- OEM Trucking

- Trucking Equipment

- Parcel Freight

- Container Shipping

- Borderlands: Mexico

- Borderlands: Canada

- Freight Industry White Papers

- Chart of the Week

- Shippers Perspective

- FW Pricing Power Index

- Energy Industry

- Weather and Critical Events

- Inside SONAR

- What the Truck?!?

- Sense per Mile

- FreightWaves NOW

- Fuller Speed Ahead

- Net-Zero Carbon

- Rethink Reshoring

- Great Quarter, Gals

- The Stockout

- Loaded and Rolling

- Running on Ice

- Freightonomics

- Put That Coffee Down

- Taking the Hire Road

- Drilling Deep

- View All Newsletters

- FreightWaves Daily

- FreightWaves Best Of

- AS Week In Review

- The Stockout (CPG & Retail)

- Running on Ice (Cold Chain)

- What The Truck

- MODES Newsletter

- Check Call (3PL News/Analysis)

- Loaded & Rolling (Enterprise Fleet News/Analysis)

- Ocean Cargo

- Truckload Index

- Value Based

- Request a Demo

- SONAR Knowledge Center

- SONAR API Explorer

- Future of Supply Chain

- The State of Freight Webinars

- FreightWaves TV Events

- Freight Sentiment Indexes

- FreightWaves Academy

- Carbon Intelligence

- Public Companies Directory

- EV Directory

- AV Directory

- FreightTech

- Shipper of Choice

- Infographics

- Market Experts

- Online Haul of Fame

- Benchmarking

- Our Mission

- Executive Team

- Editorial Team

- Our Investors

Class I railroad executives outline plans to bolster rail service

Macroeconomic uncertainties weigh on 2024 but longer-term future bright, execs say.

The ongoing theme of improving rail service as a means to capture market share away from trucking again appeared in comments from Class I railroad executives speaking at recent investor conferences.

To frame the discussion around rail service, CSX executives started by looking at what factors and conditions led market share away from rail to truck.

The railroads need to demonstrate that the service they provide is consistently reliable, according to CSX President and CEO Joe Hinrichs. who pointed to situations in which the railroads historically hauled greater volumes of motor vehicle components such as frames and sheet metal but because of inconsistencies in rail service, those volumes shifted away from rail and to other transportation modes.

Providing excellent service should be “the foundation of any discussion around growth,” Hinrichs said at Baird’s investor conference on Nov. 8. “We have industry-leading service levels, but we know there’s a lot more we can do. We’re not anywhere satisfied with where we are. We know we can get better.”

CSX CFO Sean Pelkey, speaking at Stephens’ investor conference on Tuesday, echoed Hinrichs’ remarks.

“I’ve been to several customer locations over the years. And every time I go, I’m really frustrated because I look at the number of truck bases they’ve got and all the outbound product getting loaded up into the trucks and the empty rail cars are sitting right next to them,” Pelkey said.

“But you just see the amount of opportunity that’s there. Most of the plants that are rail served, in many cases, are also truck served. So in some cases, those plants that might be running 50-50 rail and truck, can they very quickly shift to 60-40 rail? Absolutely. If we’re running well for 30 days, those kinds of shifts occur. And you know what, if we’re not running well for 30 days, they’re going to shift right back to truck very quickly,” Pelkey continued.

Other Class I railroad executives also identified the need to improve rail service.

Customers “frankly need to see rail service [reach] targeted levels through an economic cycle,” said NS President and CEO Alan Shaw at the Stephens conference Wednesday. “There are a lot of customers right now who would want to ship more with us today if we could present the capacity to them. … I know there’s a lot more out there as we continue to demonstrate our ability to deliver good service in an economic cycle.”

Union Pacific CEO Jim Vena noted that providing excellent service can mean different things to different customers. What parcel companies might define as excellent service may differ from what bulk customers may want. Some customers might want UP’s trip compliance to be in the high 90s, while other customers might place a premium on how fast UP can turn rail cars, Vena said Tuesday at the Stephens conference.

“I know that we can grow this business. If you go around our network, there are so many things that we can do to leverage it. We have to understand that not only can we win when we’re competitive against other railroads — if we’re the best and we have the best margin … but we can grow with our customers and we can leverage our network that we have and the kind of products that we move and in Mexico,” Vena said.

How the railroads plan to bolster rail service

To improve rail service, Hinrichs said one way is to focus on the outlying factors.

“It’s not just did your car load or did your intermodal train get there on time, but also were we there when you need us to load empties,” Hinrichs said. “We need to reduce the standard deviation of outliers. If we get there 90% of the time but the other 10% [is] five days late, that’s a huge problem, right? It’s not just on the averages. We’ve got to narrow the standard deviation of our performance.”

Moving data onto the cloud can also be a way to enable more efficient real-time decisions and help CSX ( NASDAQ: CSX ) improve its trip plan compliance in the next 24 to 72 hours, Pelkey said.

“There’s more meat that needs to be put on the bone in terms of the way that we share that with investors and that will come in time. But our investment in technology has gone up a little bit,” said Pelkey, who pointed out those investments help bolster rail safety through autonomous track inspection and predictive technology to ensure locomotive health.

According to Vena, one key advantage that UP ( NYSE: UNP ) has over its peers is speed. The railway can run up to 70 miles per hour on certain stretches of its network, including from Omaha, Nebraska, westward. Another advantage is UP’s access to six gateways at the U.S.-Mexico border, as well as its 26% ownership of the FXE Railroad in Mexico.

UP needs to optimize its accessibility to West Coast ports 一 and not just focus on the ports of Long Beach and Los Angeles, but also partner with others in Portland, Oregon, Seattle and Oakland, California, Vena said.

As Vena alluded to during UP’s third-quarter 2023 earnings call in October, the railroad is also seeking to streamline decision-making within the company by enabling those closer to day-to-day operations to make operating decisions. The company recently said it targeted layoffs of 5% of its 5,600 managerial employees as a way to reduce the bureaucracy in UP’s decision-making process.

“We had nine layers to go from myself down to the people … doing the work in the operating department. There’s no way that you need that many people,” Vena said, adding that those laid off were offered positions elsewhere in the company, including some unionized roles as locomotive engineers and conductors.

Vena described decision-making at a level closer to day-to-day operations as a way of shifting the company culture. “You frame exactly what the authority is. You let people have that authority. You let them make it at the right level. The young man who today works at El Paso has a way better idea of what the impacts are. And if he understands [that] the goal is to provide the service we sold to the customer … as efficient[ly] as possible, when he’s … seeing what traffic has come to the border for the day, he has a way better idea to be able to say, ‘How do I use those crews in a better manner?’”

That effort to change company culture, coupled with day-to-day operational goals such as running longer trains and sweating assets, also helps UP maintain productivity during times of economic downturn, according to Eric Gehringer, UP executive vice president of operations.

When UP is sweating its assets, “you’re really trying to figure out with every day and every decision that’s made, how do you do that better today than you did yesterday?” Gehringer said at the Stephens conference.

Class I rail executives look ahead

Executives were hesitant to speculate when macroeconomic conditions might improve in 2024.

Geopolitical instability globally is another factor that could weigh on the railroads’ marketing prospects, according to Shaw. But the e-commerce peak, which occurs after Thanksgiving, should provide NS ( NYSE: NSC ) with a boost.

Nonetheless, despite next year’s uncertainties, “we have the capacity to handle more business and we’re attracting more business,” Shaw said, noting that in the last six to seven weeks, NS is seeing volumes at levels not seen in 18 months amid improving network fluidity.

Vena said UP aims to outpace growth in the industrial economy.

“We need to be excellent at service so that our customers and other customers that look at the railroad industry say, ‘We want to be on the railroad.’ That’s where our growth is going to be and the business is out there. … So where would I be happy? I think I’d be happy that we grew faster than what the industrial economy gives us. And that’s a goal to start off with. That would not be my long-term goal, but let’s get there first.”

As for a longer-term view of where UP plans to position itself in the next three to five years, the railway is considering hosting an investor day sometime in the back half of 2024, according to CFO Jennifer Hamann, who noted that will depend on where the economy shakes out.

Meanwhile, CSX and NS executives pointed to future industrial development opportunities in growing population areas such as the U.S. Southeast.

This dynamic of industrial development “is as exciting as it’s been in my nearly 20-year career at CSX. I don’t think we’ve seen this much activity in those two decades,” Pelkey said.

Potential opportunities in 2025 and 2026 for CSX could come from automotive production plants in the Southeast, such as the Rivian plant outside Atlanta, the Ford plant outside of Memphis, Tennessee, and the Hyundai plant in Georgia, according to Hinrichs, who said hauling aggregates because of construction activities is another potential opportunity for CSX.

Shaw also noted manufacturing growth in the Southeast as well as the Midwest. For instance, the electrical vehicle market is worth $70 billion in North America, with $30 billion of that occurring near NS’ network.

“I’m really confident that we’re going to have a lot of strength in our merchandise franchise going forward because of onshoring,” Shaw said.

Recently announced partnerships among the railroads, such as NS’ partnerships with Canadian railway CN and Florida East Coast Railway, could also help to grow rail volumes, according to Shaw.

“We have to think of ourselves as competing in this supply chain ecosystem. And if all we’re doing is throwing costs over the fence at a customer or a short line partner, that end-to-end solution probably isn’t going to be effective, and it’s probably not going to win versus truck. We’ve got to partner with them to make that interface much more efficient. And that’s ultimately how we’ll win,” Shaw said.

Subscribe to FreightWaves’ e-newsletters and get the latest insights on freight right in your inbox .

Click here for more FreightWaves articles by Joanna Marsh .

Related links:

- Norfolk Southern says higher costs will pay off in long term

- CSX COO says internal, industry collaboration key to capitalize on opportunities

- Union Pacific’s new CEO wants to win

One Comment

Growersexchange,inc.

We will just see

Comments are closed.

Joanna Marsh

Ultimate Guide to Rail Shipment Management: Part 3 – Railcar ETA to Destination

Railroad performance metrics.

Our previous articles covered the core operating metrics of the railroad’s report, showing us how train speed and yard dwell are helpful indicators rail shippers can use to measure the health of the rail network. These metrics can highlight problem areas also, but they do not help shippers manage their shipments to reach their destination on time.

Check out the first article in our series where we discuss railroad operating performance, from trip plan compliance, how rail shipment ETAs are calculated and how rail shippers can use these metrics to improve their rail network.

Trip Plan vs ETA

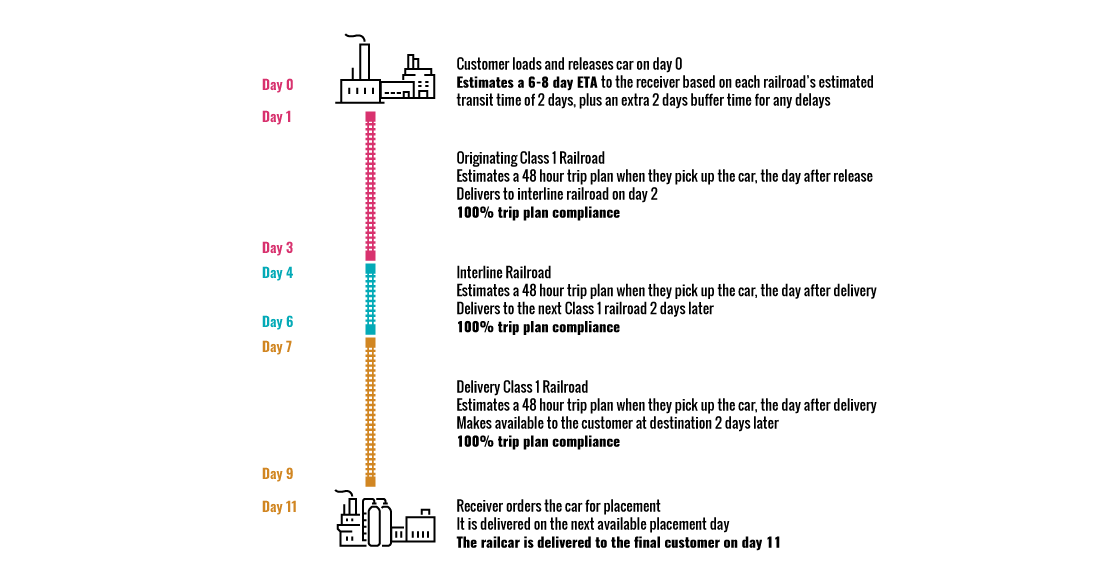

Some class 1s created Trip Plans to predict shipment arrival to destination (or delivery to the next railroad in the route), but Trip Plan alone does not tell rail shippers when the railcar will arrive. Most rail shipments cross multiple railroads to reach the final destination, yet Trip Plans are unique to each railroad. The other challenge is that Trip Plans only predict availability at the destination, not the actual last-mile delivery to the customer.

As a result of these “no man’s land” zones in transit, a shipment can be 100% on-time by the railroad standards but arrive more than 50% delayed to the sum of the original Trip Plans. How can this occur?

The infographic below shows how a shipment can be delayed at multiple transit points.

“Scenarios like this are more common than we may realize. Rail shipments “go dark” at different points in the supply chain every day .”

Typical scenarios include handoffs between class 1s when the railcar is not “on the clock” for either railroad, short lines with no visibility to in-transit updates, and the first mile/last mile where the railroad has stopped the clock. However, the receiver is still waiting for the shipment to arrive.

Rail Shipments Need End-to-End Predictive ETAs

A shipment ETA is different from a Trip Plan: a rail shipment ETA is calculated when the car is billed and released to the railroad and predicts arrival to the final destination . Rail shipment ETAs can be recalculated at each in-transit location as the railcar passes by trackside AEI readers. This helps the ETA become more accurate as the car gets closer to the destination.

Features of rail shipment ETAs that shippers should also look for include:

- Logic to recalculate the ETA when the railcar is dwelling, whether at a yard or in transit

- Logic to recalculate the ETA when a railcar is reported wrong order or on hold by the railroad

- Logic to incorporate a day of week service variations in the calculation

- A data model based on historical operations data, as opposed to railway transit estimates

- Automated intelligence that continuously cleans and improves the data model – for example, it should remove outliers and adjust to trends in performance, seasonality, and location or customer-specific dwell

Rail ETAs Enabling End Customer Success

ETAs are no longer optional; freight customers expect their business life to mirror their personal experience more closely. If they can know up to the minute when a $10 item from Amazon will arrive, why don’t they know where $10,000 worth of industrial goods is, never mind what day it might arrive?

Logistics is now a competitive advantage; if you consistently predict when products will arrive at receivers, they are more likely to remain loyal customers and more likely to pay a premium. 63% of buyers in a recent supply chain study found that transparency in transit was the top item on their wish list .

Visibility can be time-consuming for the logistics team without the right tools; even if shippers attempt to build a buffer around railroad trip plans, logging into each railroad’s system to answer a simple customer ETA request is not the best use of the rail traffic coordinator’s time.

A Better Option for Shippers is to Consolidate Information Across All Railroads in a Central Railcar Tracking System

Some of these systems have advanced ETA algorithms built-in, including ICL’s RSVP rail tracking system.

Using RSVP, rail logistics managers can set up automated reports emailed to the customer directly, containing each shipment’s ETA and current location in transit. The reports can be customized for each receiver’s preferred content, layout, and frequency.

This is a win-win solution: shippers who automate the communication of ETAs to the customer can focus their time on higher-value activities while improving their customers’ experience.

Software solutions like RSVP can also help shippers optimize their rail assets – receivers who have automated ETA reports can plan unloading schedules more effectively, ultimately reducing the cycle time of the railcar.

Improved rail ETAs and better visibility to shipments in transit are some of the benefits ICL’s customers experience using our software.

Contact our sales team to learn more or request a no-obligation demo .

Be Part of the Ultimate Safety & Compliance Community

Trending news, knowledge-building content, and more – all personalized to you!

Trip planning

In its simplest form, trip planning is the art of figuring out how to get from point A to point B safely, legally, and on time before getting behind the wheel of any car, bus, straight truck, or semi tractor-trailer.

All professional drivers should make trip planning a habit to ensure that they are able to deliver their cargo safely and on time while maintaining compliance with the Federal Motor Carrier Safety Regulations (FMCSRs) .

Regulatory citations

- 49 CFR 392.3 — Ill or Fatigued Operator

- 49 CFR 395.8(a)(1)(i) — Driver’s Record of Duty Status

Key definitions

- Personal conveyance (PC): Personal use of a commercial motor vehicle for personal purposes only when a driver is completely relieved of all responsibility for work. This is also called off-duty driving.

- Electronic logging device (ELD): A device or technology that automatically records a commercial motor vehicle (CMV) driver’s driving time and aids in the accurate recording of the driver’s hours of service by being integrally synchronized with the engine control module (ECM) of the vehicle. The ELD replaced the need for paper records of duty status (logs). Under federal rules, ELDs became mandatory for most interstate CMV drivers December 18, 2017.

Summary of requirements

Proper trip planning takes into account such things as hours needed to complete a run, total miles of a run, time of day, city vs. highway driving, the hours of service regulations (if applicable), and weather conditions. Proper trip planning also requires basic map (atlas) reading ability and time management skills.

Most customer service failures (late pick-ups or deliveries) occur as a result of either a poor trip plan, or a poor execution of a proper trip plan.

Speed limits. FMCSA guidance on trip planning conveys that drivers are required to conform to the posted speed limits prescribed by the jurisdictions in or through which the vehicle is being operated.

- Where the total trip is on highways with a speed limit of 65 mph, trips of 550-600 miles completed in 10 hours are considered questionable and the motor carrier may be asked to document that such trips can be made.

- Trips of 600 miles or more will be assumed to be incapable of being completed without violations of the speed limits and may be required to be documented. In areas where a 55 mph speed limit is in effect, trips of 450-500 miles are open to question, and runs of 500 miles or more are considered incapable of being made in compliance with the speed limit and hours of service limitation.

Electronic logging devices. Electronic logging devices should provide accurate hours of service available for planning purposes. If drivers are allowed to log on manual logs for 8 or less days in any 30-day period, the dispatch process should take into consideration of hours reported by drivers in their check-in calls.

Hours of service. A carrier’s specific trip-planning policy must require drivers to be dispatched on trips that can be done within the available hours of service including all tasks from the start of a dispatch through delivery and any waiting time that is required to be logged as on-duty time. Drivers may not drive ill or fatigued in violation of 392.3 and a carrier may not allow a driver to become ill or fatigued.

Stopping points. Trips should also be planned with an approximate stopping point each day so the driver can safely and legally reach a reasonable and safe place to park with appropriate facilities. With scarce parking in some areas at certain times of day, drivers must plan for an appropriate stopping time that may be well before they completely exhaust their available hours. Drivers cannot use personal conveyance to reach a park location if they run out of hours, unless they are leaving a shipper or receiver after loading or unloading delays.

Interruption of driving time. Under 395.3(a)(3)(ii) , a property-carrying driver not using either 150 air-mile exception from logging in 395.1(e) must plan for a 30-minute break from eight total hours of driving when applicable.

Website maintenance on Trains.com is now complete and action may be required on your account. Learn More .

Why Sign In? Subscribers, sign in to access exclusive content. Unlimited Members, sign in to enjoy sitewide access.

News & Reviews News Wire Management incentives at CSX, NS, and UP shift toward service and growth

Management incentives at CSX, NS, and UP shift toward service and growth

Railroads’ annual bonus plans encourage on-time performance and traffic growth

Email Newsletter

Get the newest photos, videos, stories, and more from Trains.com brands. Sign-up for email today!

The publicly traded U.S. Class I railroads are putting more of an emphasis on service and volume growth in the annual incentive plans they offer to their executives.

It’s a clear sign, analysts say, that the railroads are shifting into growth mode after years spent concentrating on reducing their operating ratios in a quest for higher profits.

“People will move toward what they are incented to do … it’s not just a symbolic move,” says independent analyst Anthony B. Hatch. The incentive changes are part of what Hatch calls the “pivot to growth” that follows the implementation of the ultra-lean Precision Scheduled Railroading operating model.

The annual incentive plan changes are the most pronounced at Norfolk Southern, which in December unveiled a long-term service and growth strategy .

Last year, the annual bonus formula was built 50% on operating ratio improvement, 30% on operating income, and 20% on corporate goals. For 2023 the operating ratio component is gone. The formula is now based 40% on operating income, 30% on revenue growth, 10% on merchandise on-time performance, 10% on intermodal on-time performance, 5% on improving the employee injury rate, and 5% on improving the train accident rate.

CSX Transportation reduced its operating ratio component from 35% a few years ago. Now the short-term bonuses are weighted 30% on operating income, 30% operating ratio, 10% new traffic growth, 10% safety, 10% fuel efficiency, and 10% trip-plan compliance.

Union Pacific has tweaked the annual incentive formula it introduced in 2018. The formula is based 35% on operating income, 35% on operating ratio, 20% on the “corporate scorecard,” and 10% on individual performance. The scorecard is where UP has introduced carload growth, market share, trip-plan compliance, and net promoter score, which is a measure of customer satisfaction. The other scorecard components include employee engagement, personal injury rate, reportable derailment rate, and renewable fuel blend.

The annual bonus programs can provide up to 25% of an executive’s total compensation and are designed, along with long-term incentive plans, to ensure that management pursues the goals set by the board of directors.

Nick Little, director of railway education at Michigan State University’s Center for Railway Research and Education, is encouraged by the changes in management compensation. “I would best sum it up that NS and CSX are better aligning their executive incentives with stakeholder satisfaction rather than shareholder satisfaction,” he says. “Next, I’d like to see an element of the incentive scheme based upon a customer experience index and also upon staff/employee satisfaction indices.”

Peter Swan, an associate professor of logistics and operations management at Penn State Harrisburg, says there’s no question incentives work. But they can backfire if they’re not carefully structured.

In the 1980s, when Swan was in the marketing department at CSX, there was an incentive to reduce fuel costs. The easiest way to do that is reduce horsepower-per-ton ratios, Swan says, which CSX management did with gusto. The result was burned out traction motors, a network slowdown, and more trains holding for power — all of which took a toll on service and likely raised costs overall.

Gaining new business is far harder than cutting costs. Among the things railroads need to do to grow, Swan says, is go beyond incentives and restore surge capacity in the form of crews, locomotives, and freight cars.

Getting away from managing to the operating ratio also will help. “If you manage just by operating ratio you really limit growth,” Swan says.

Little agrees. “A focus on OR (or net profit margin) as a sole driver of company performance is, and always has been, a shorter term goal since there are structural limits to how far O.R. can be cut or margins increased without losing business,” he says.

But a focus on service and growth won’t necessarily nudge the operating ratio upward. “If you’re running a railroad right — for customers, in ways that the Surface Transportation Board would approve of — your O.R. should not suffer,” Hatch says. “It should get better.”

Swan says incentive plans that balance financial, service, growth, and safety goals are overdue. “Right now the industry has successfully angered every stakeholder group except shareholders,” he says.

The Canadian railways, which have grown at more than three times the rate of the big four U.S. systems over the past decade, also include service and customer elements.

Canadian National’s annual incentive plan is based 70% on financial performance (35% on operating ratio, 35% on operating income, 30% on free cash flow); 20% on corporate strategic performance (weighted equally on fuel efficiency, employee engagement, and customer centricity), and 10% on safety.

Canadian Pacific’s plan, set before its merger with Kansas City Southern, is based 35% on operating ratio, 35% on operating income, 10% on the train accident rate, 10% on the employee injury rate, and 10% on trip-plan compliance.

Related Topics

7 thoughts on “ management incentives at csx, ns, and up shift toward service and growth ”.

I agree with Paul…

I’ve got three and a half years to retire…I’d like to see this bear significant and copious fruit before I go!

Can we get a “Howl Lah Lu Lu”?

It will be hard to change management mentality. Working as a conductor, I once asked a division gm why we didn’t go after more smaller business customers. I was told there wasn’t enough money there. I really hope they stick to the new plan.

What a novel idea; will wonders never cease?

Likely post-East Palestine posturing that will quickly evaporate after the CEO gets fired by the investors as soon as the OR increase or the dividends drop.

Lets hope that the Railroads are serious about this. A move in the right direction.

NTSB issues final report on NS conductor trainee killed by steel that penetrated locomotive cab

Caltrain fully energizes electrified corridor

Brown, Inman sworn in as NTSB members

Schulte named president of Anacostia’s Northern Lines Railway

Shop our Hobby Store

Members enjoy 15% off any purchase in our store. Join Today !

How Diesel and Electric Locomotives Work

After reading this book, you will understand what is happening inside the next locomotive you see!

Great American Steam Locomotives: Articulateds DVD

Articulateds capture the heart and minds of anyone who comes out to see them.

Steam Across America

See historic power come alive in this all-new special issue from Trains magazine!

Milwaukee Road Metal Sign

Celebrate the Milwaukee Road with this metal sign

Stay updated

Get updates and special offers via email from Trains.com brands!

- Toolbox Talks

Maximizing Safety on Your Next Adventure: Essential Trip Planning Tips for HSE Compliance

- by Afnan Tajuddin

Embarking on an adventure, whether it’s scaling a rugged mountain, exploring remote wilderness, or simply camping out in the great outdoors, is an exhilarating experience. However, the thrill of adventure should never compromise safety. Adhering to Health, Safety, and Environment (HSE) guidelines is paramount to ensuring not just your well-being but also that of your team and the natural environment you’re exploring. In this comprehensive guide, we’ll walk you through essential trip planning tips to ensure your next adventure is not only memorable but also aligns with the best practices in HSE compliance.

Table of Contents

Understanding the Importance of HSE in Adventure Planning

Before diving into the specifics, it’s crucial to grasp the significance of HSE in the context of outdoor adventures. Health Safety and Environment (HSE) principles are designed to mitigate risks associated with physical health, safety hazards, and environmental impact. By integrating these principles into your trip planning, you’re taking a proactive step towards preventing accidents, injuries, and environmental degradation.

Key Components of HSE Compliance

- Health: Ensuring that all participants are physically and mentally prepared for the adventure, including fitness levels, medical conditions, and dietary needs.

- Safety: Implementing measures to prevent accidents and injuries, such as using appropriate gear, conducting safety briefings, and establishing emergency protocols.

- Environment: Minimizing the ecological footprint of your adventure by practicing Leave No Trace principles, managing waste, and respecting wildlife habitats.

Step-by-Step Guide to Planning a Safe and Environmentally Friendly Adventure

Planning is the cornerstone of any successful and safe adventure. Here’s a step-by-step guide to ensure your trip is in line with HSE best practices:

Step 1: Conduct a Risk Assessment

Begin by identifying potential hazards related to your specific adventure. Consider factors such as terrain, weather conditions, wildlife, and the physical condition of participants. Assessing risks early on will help you prepare adequately and implement necessary safety measures.

Step 2: Gather Essential Safety Gear

Based on your risk assessment, compile a list of essential safety gear. This may include personal protective equipment (PPE), first aid kits, navigation tools, and communication devices. Ensure all equipment is in good working condition and that participants are trained in its use.

Step 3: Plan for Environmental Protection

Integrate environmental protection measures into your trip planning. This includes planning routes that minimize ecological impact, adhering to established trails, and ensuring all waste is packed out. Educate your team on the importance of preserving natural habitats and the principles of Leave No Trace.

Step 4: Develop an Emergency Response Plan

Despite the best preparations, emergencies can still occur. Develop a comprehensive emergency response plan that includes evacuation routes, emergency contact numbers, and protocols for managing injuries or other critical situations. Ensure all participants are familiar with this plan.

Step 5: Conduct Pre-Trip Briefings

Before setting out, conduct a thorough briefing with all participants. Cover essential topics such as trip itinerary, safety protocols, environmental guidelines, and emergency procedures. This is also an opportunity to address any questions or concerns and ensure everyone is on the same page.

Best Practices for HSE Compliance During Your Adventure

Adhering to HSE guidelines doesn’t stop at the planning stage. Here are some best practices to maintain compliance throughout your adventure:

Maintain Constant Vigilance

Stay alert to changing conditions and potential hazards. Regularly check in with your team members regarding their health and well-being, and be prepared to adjust your plans as necessary.

Practice Responsible Environmental Stewardship

Lead by example in practicing Leave No Trace principles. This includes proper waste disposal, respecting wildlife, and minimizing your ecological footprint. Encourage your team to do the same.

Document and Learn from the Experience

Keep a record of any incidents or near-misses, along with how they were managed. After your adventure, review these experiences to identify lessons learned and areas for improvement in future trip planning.

Summary of Key Points

Planning an adventure with HSE compliance in mind is essential for ensuring the safety of participants and the protection of the environment. By conducting a thorough risk assessment, gathering essential safety gear, planning for environmental protection, developing an emergency response plan, and conducting pre-trip briefings, you can set the stage for a safe and successful adventure. Remember to maintain vigilance, practice responsible environmental stewardship, and document your experiences to continuously improve your HSE practices. Embrace these essential trip planning tips, and embark on your next adventure with confidence and peace of mind.

Adventuring with a keen awareness of Health, Safety, and Environment (HSE) principles not only ensures a safer experience for everyone involved but also contributes to the preservation of the beautiful and wild places we seek to explore. Let’s adventure responsibly, with safety and sustainability at the forefront of our planning and actions.

Share this:

Leave a reply cancel reply.

IMAGES

VIDEO

COMMENTS

CSX's intermodal trip plan compliance fell 11 percentage points YoY to reach 84%, which it blamed on higher levels of volume from UPS than it was expecting. This resulted in some international traffic taking "a little longer to get off the port than we normally would to make sure we move the time sensitive traffic," CSX CEO Jim Foote said.

The railroads' internal trip-plan compliance figures generally are much tighter than what they are required to report to the board, however. The historic data trail starts in May 2019, although the railroads provided different types of on-time performance information to the board. BNSF and NS provided an all-in number, for example, while CSX ...

Trip Plan Compliance is a new metric now reported by the Class 1 Railroads and is related to Precision Scheduled Railroading. After implementing operating improvements (train speed, yard dwell, car velocity), railroads can measure the impact through the performance of shipments to specific ETAs:

Trip Plan Compliance (TPC; placement within 24 hours of the original estimated time of arrival): "System-wide TPC (manifest) for CSX pursuant to [STB] metric 7(i) is 69% for week 19 (the week ending May 13, 2022)," the Class I railroad reported. "At the end of the six-month reporting period, CSX expects that TPC (manifest) pursuant to ...

Car Trip Plan Compliance (on-time shipment delivery) - Manifest/auto trip plan compliance improved by three percentage points to 74% compared to a year ago, while intermodal trip plan compliance was 82%, down one percentage point from 2019. We are working closely with you, our customers, and our operating team to make sure we have adequate ...

The railroads' internal trip-plan compliance figures are much tighter than what they are reporting to the board. The railroads have said that crew shortages are the culprit for erratic service and congestion on their networks. The shortages have been compounded by not having locomotives in the right places at the right times as well as the ...

The purpose of Trip Plan Compliance is to measure success in meeting CSX's end-to-end commitments to moving customer railcars. The measure captures performance against the planned estimated time of arrival (ETA) commitment. It is not measuring train or yard performance.

The railroad says it's focusing on four metrics beyond what the board required, including trip plan compliance, first/last mile service, average train velocity, and average terminal dwell. CSX says it has no systemwide velocity restrictions in place. "It is CSX's intention to move at track speed whenever possible," the railroad says.

CSX recently reported first quarter intermodal trip plan compliance results above 95 percent, demonstrating its strong record of meeting rail car scheduling plans. The company's improved service ...

Dive Brief: Kansas City Southern plans to focus more on improving trip plan compliance for customers, Sameh Fahmy, executive vice president for precision scheduled railroading, said on the company's Q3 earnings call Friday. " We are measuring the traffic of our customers and the connection times and how they [are] missing the connection from train to train, " Fahmy said of the company's ...

As measured by trip plan compliance (CSX calls it TPC)—as the success in meeting end-to-end customer commitments based on estimated times of arrival—CSX's service performance at the carload level had actually statistically improved initially from the low-60% range to the mid-80% range. From a CSX quarterly investor presentation: Figure 1

CSX reached its lowest operating ratio to date, 56.8%, in the third quarter of 2019. The figure, in which a lower number indicates greater profitability for the railroad, is down 1.9% year-over-year, executives noted in the company's third quarter earnings release . Trip plan compliance, which CSX began reporting last year as a gauge of ...

UP also calculated an estimated carload TPC (trip plan compliance) estimated target. ... NS appears to state that it does not use trip compliance analysis to measure the quality of its growth product "intermodal sector." That seems out of touch with what truckers and other railroads do. To comply with the STB request, it calculates a 24 ...

As measured by trip plan compliance (TPC) — or the success in meeting end-to-end customer commitments based on estimated times of arrival — service performance is registering percentages in ...

Moving data onto the cloud can also be a way to enable more efficient real-time decisions and help CSX (NASDAQ: CSX) improve its trip plan compliance in the next 24 to 72 hours, Pelkey said. "There's more meat that needs to be put on the bone in terms of the way that we share that with investors and that will come in time.

Rail Shipments Need End-to-End Predictive ETAs. A shipment ETA is different from a Trip Plan: a rail shipment ETA is calculated when the car is billed and released to the railroad and predicts arrival to the final destination. Rail shipment ETAs can be recalculated at each in-transit location as the railcar passes by trackside AEI readers.

FMCSA guidance on trip planning conveys that drivers are required to conform to the posted speed limits prescribed by the jurisdictions in or through which the vehicle is being operated. Where the total trip is on highways with a speed limit of 65 mph, trips of 550-600 miles completed in 10 hours are considered questionable and the motor ...

Now the short-term bonuses are weighted 30% on operating income, 30% operating ratio, 10% new traffic growth, 10% safety, 10% fuel efficiency, and 10% trip-plan compliance. Union Pacific has tweaked the annual incentive formula it introduced in 2018. The formula is based 35% on operating income, 35% on operating ratio, 20% on the "corporate ...

CSX Uncovers Trip Plan Compliance. CSX is taking a bold transparency move. In releasing its Trip Plan Compliance performance information, it is also at the early stages of disclosing how poor logistics delivery to customers has been in the past. But, to correct and improve, it is necessary to admit the depth of the service challenge.

4. Car trip plan compliance measure: BNSF's customers focus on metrics that are most closely related to the use of equipment and the overall capacity of the network. Therefore, BNSF focuses on Trips per Month for our unit train service and system velocity. a. Trips per month: YTD Ag Shuttles 2.6; Ag General Fleet 1.1 b.

Planning an adventure with HSE compliance in mind is essential for ensuring the safety of participants and the protection of the environment. By conducting a thorough risk assessment, gathering essential safety gear, planning for environmental protection, developing an emergency response plan, and conducting pre-trip briefings, you can set the ...

Dive Brief: Union Pacific's intermodal trip plan compliance fell 4% YoY in Q3 as volume came back to the railroad nearly as quickly as it dropped in Q2, Chief Operating Officer Jim Vena said on a Thursday earnings call. "When we walked into the third quarter, the entire supply chain was constrained.

The Surface Transportation Board (STB) on Sept. 7 issued a Notice of Proposed Rulemaking (NPRM) that it said focused on "providing rail customers with access to reciprocal switching as a remedy for poor service." It called the move "an important step in addressing the many freight rail service concerns expressed by stakeholders since 2016." Comments are due by Oct. 23, and STB said it ...