- Register / Login

- Trucker's Forum

- Paid CDL Training

- Truck Driving Jobs

- CDL Practice Tests

- High Road Training

Pre-Trip Inspection Study Guide

Our Pre-Trip Inspection Study Guide has everything you need to prepare for the Class A CDL Pre-Trip Inspection Exam . Our study guide will cover the pre-trip inspection terminology as well as a thorough list of all of the parts you will be inspecting on the vehicle. For each part you will be inspecting there will also be a list of items you will be checking for. Our study guide is broken down into the following sections:

- What You Need to Know About Pre-Trip Inspection

Pre-Trip Inspection Practice Questions

- Pre-Trip Inspection Checklist

Pre-Trip Inspection Videos

Pre-trip inspection printable resources, what you need to know about the pre-trip inspection.

The Pre-Trip Inspection is a thorough inspection of the vehicle and all of its major systems. Inspecting the vehicle before driving each day is a Federal requirement and normally takes about 15 minutes. It must be logged in your logbook as "on duty not driving."

You will have to do thorough safety inspections of the coupling system, the vehicle lights, engine compartment, tires and brakes, the chassis, the fuel tanks, and an in-cab inspection.

The following information is a brief summary of Daniel's Complete Pre-Trip Inspection taken from our oustanding free PDF download:

Engine Compartment

You will be checking the engine compartment for any sort of leaks. You will also be checking to see if all components are properly mounted and secured. None of the mounts must be cracked, bent, or broken.

You will be checking all hoses to make sure they aren't leaking, frayed, or sliced and the fluid levels including the oil level, the coolant, and the power steering fluid.

You must check the components like the water pump, the power steering pump, and the alternator to make sure nothing is leaking, the belts are not frayed, and that everything is properly mounted and secured.

From inside the engine compartment you will also find the steering system, the front suspension system, and the front brake system. All components of these systems must be properly mounted and secured without anything being cracked, bent, or broken. Finally you will be checking the tires, rims, and axle seals to make sure the tires are properly inflated, the rim isn't bent or cracked, and the axle seals are not leaking.

Fuel Tank And Battery Area

You will be standing along the side of the tractor doing a series of checks on the mirrors, fuel tanks, batteries, exhaust system, and more. You will check to make sure nothing is bent, cracked, broken, or leaking.

Check the mirrors, door hinges, door handle to make sure nothing is cracked, bent, or broken. Check to make sure there is no fuel leaking and that the fuel cap is secured and the gasket is not missing.

Check the exhaust system to make sure nothing is cracked, bent, or broken. Check the driveshaft, cat walk, and steps to make sure nothing is cracked, bent, or broken.

Check the frame and crossmembers for structural integrity. Check the air lines going to the trailer to make sure they're properly connected and that there are no abrasions, bulges, or cuts. Make sure the gaskets are present.

Check the suspension system and brakes on the drive axles, making sure nothing is cracked, bent, or broken. Make sure the brake linings are the proper thickness and that the air bags and properly inflated. Inspect the brake chambers, slack adjusters, and pushrods are properly mounted and secure. Not Cracked, Bent, or Broken. With the brakes released and pulled by hand, the Push Rod should not move more than 1 inch.

Check the rims, tires, and axle seals of the drive tires for proper inflation, no leaks around the seal, and the lugs are all present and secured.

Coupling System

You will be standing where the tractor and trailer are connected and you'll start by checking the electrical line and air lines to make sure they're properly mounted and secure at both ends. No abrasions, bulges or cuts. Not leaking air. Make sure the electrical line has no wires exposed. Check the gladhands to make sure the seals are in good condition, no cracks or signs of dry rotting. Not leaking air.

Check the skid plate of the fifth wheel and the apron of the trailer to make sure there is no debris and nothing is cracked, bent, or broken. Make sure the fifth wheel is properly greased. Also make sure there is no gap in between the fifth wheel and the trailer apron once the tractor and trailer are coupled. Make sure the kingpin of the trailer is properly mounted and not cracked, bent, or broken and that the locking jaws of the fifth wheel are properly secured when the tractor and trailer are coupled.

Check the mounting bolts where the fifth wheel attaches to the tractor frame. Make sure there are no missing bolts and that everything is secured properly. Check the locking pin if you having a sliding fifth wheel to make sure it's properly locked into place.

Make sure that there is the proper clearance space between the tractor mudflap and the trailer landing gear so that they don’t hit each other when making a turn.

You will start inspecting the trailer at the head board, which is the front wall of the trailer. Make sure there are no holes or missing rivets. Check the landing gear to make sure it is properly mounted and secure. Not cracked, bent, or broken. Make sure the fully raised and the handle is secure in the cradle when the tractor and trailer are coupled.

Check the frame and crossmembers under the trailer to make sure they're not cracked, bent, or broken. Check the tandem frame and release pins to make sure the frame is in good condition and the release handle and locking pins are in the fully locked position.

You will check the entire suspension and brake system for the trailer tandems the same way you did for the drive axles of the tractor. You will also make sure the mudflaps are properly secured. For dual tires check to see that there is proper space between the tires and there is nothing stuck between the tires.

Check the rear door and hinges to make sure they are properly mounted and nothing is cracked, bent, or broken. Make sure the door seals are not worn, torn, or dry rotted.

Light Check

You will be checking all of the lights and reflectors on both the tractor and the trailer. Check the reflectors and reflective tape to make sure they are properly mounted and secure, not cracked, bent, or broken, and clean and illuminated. Check that you have the proper color of amber to the front and sides, and red to the rear.

Start by turning on your marker lights and headlights. Now walk around the entire truck and trailer and point out the lights. Give the function of the light and the location. You should then ask your examiner to help you check your five functions.

While you're sitting in the drivers seat, the examiner will stand to the front of the truck, then behind the trailer. He will then check your Turn Signals, Four Way Flashers and Brake Lights. You must do each function at every location.

The five locations that you must check your lights:

- Front of the Truck

- Both sides of the Truck

- Rear of the Truck

- Both sides of the Trailer

- Rear of the Trailer

The Five Functions you are checking for:

- Left Turn Signal

- Right Turn Signal

- Four Way Flashers

- High Beams/Low Beams

- Brake Lights

In-Cab Inspection

The in-cab inspection and air brake check will cover the various gauges and systems inside the cab along with several tests to make sure you air brake system is working properly.

You will start by checking the following:

- Seat Belt- Properly Mounted and Secure. Not ripped or frayed Adjusts and latches properly.

- Fire Extinguisher- Properly Mounted and Secure. Fully charged

- Three Red Reflective Triangles- My three red reflective triangles are GIVE LOCATION

- Spare Electrical Fuses- My spare electrical fuses are GIVE LOCATION

- Volmeter, Oil Pressure Gauge, Water Temperature Gauge, and Air Pressure Gauge all show proper operation

- City horn and air horn functioning properly

- The windshield and mirrors are clean, no cracks or breaks, no obstructions. The mirrors are in proper adjustment.

- Windshield Wipers and Washers - Demonstrate that the washers work by spraying the windshield. The Wipers are: Properly Mounted and Secure and operate smoothly. The blades aren't cracked or dry rotten.

- Heater and Defroster - Demonstrate that both the Heater and Defroster are working properly.

- Lighting Indicators - Left Turn, Right Turn, Four Way Flashers, and High Beams.

Trailer Parking Brakes - Set the Trailer Brake, release the tractor brake, and then tug lightly on the trailer.

Tractor Parking Brakes- Then set the Tractor Brake, release the trailer brake, and then tug lightly on the tractor.

Service Brake Check - Release both Tractor and Trailer Brakes. Now drive at idle speed. Apply the Service Brake to make sure you come to a complete stop, and that it doesn't pull to the left or right when applying the brakes.

Air Brake Test

The air brake test will consist of a leakdown test to make sure your air brakes aren't leaking air and losing pressure. It will also test the warning lights and buzzer to make sure the driver gets the proper warning if the air pressure drops too low.

There are three stages to an Air Brake Test

#1: Applied Pressure Test

#2: Warning Light and Buzzer

#3 Tractor/Trailer Protection Valve Pop Out

Applied Pressure Test: Build the air pressure to governor cut out. Put the truck in the lowest gear. Then turn off the engine Immediately turn the engine back on. Push in both the tractor and trailer valves. (This will release the parking brakes.) Push and hold the Brake pedal fully. Allow the gauges to stabilize. Announce the gauges have stabilized and the Primary and Secondary PSI. With the Brakes fully pressed, you should not lose more than 4 PSI in one minute. Announce that you are listening for air leaks during that minute.

Warning Light and Buzzer Test: Pump down on the Brake pedal until the warning light and buzzer comes on, at or before 60 PSI.

Tractor/Trailer Protection Valve Pop Out Test: Pump down on the brake pedal until both the tractor and trailer protection valves pop out. They should both pop out between 40 and 20 PSI.

We have a ton of Pre-Trip Inspection Practice Questions along with the answers and a complete scoring system in our Free Online CDL Practice Tests :

The Engine Compartment Section will include questions about checking the oil level and coolant levels, inspecting belt-driven engine components (like the water pump, alternator, and air compressor), and the safety devices required in the cab. There will also be questions regarding the windshield wipers and free play in the steering wheel.

The Lights And Brakes Section will include questions about dashboard indicator lights, inspecting the parking brakes, and doing a leakdown test on the air brakes. It will also include questions about the low air pressure warning signal and testing your air horn and city horn.

The Suspension And Steering Section will include questions about the tractor protection valve, inspecting the steering box, and inspecting many suspension system parts. It will also include questions about welds being present on tire rims and the minimum tread depth required on steering axle tires.

The Tires And Coupling Devices Section will include questions about shiny trails or rusty threads on lug nuts, inspecting the battery box and cover, and inspecting electrical lines. It will also contain questions about inspecting the coupling devices and the fifth wheel skid plate.

The Emergency Equipment And Fifth Wheel Section will include questions about additional emergeny equipment required by school buses, inspecting the gap between the kingpin apron and the fifth wheel skid plate, and the landing gear securement. It will also contain questions about inspecting driver mirrors and the trailer frame.

Pre-Trip Inspection Checklist - Class A

Our pre-trip inspection checklist covers every part of the truck from front to back, both inside and outside of the truck. It covers the air brakes, suspension parts, steering components, wheels and rims, fuel tanks, batteries, lights, and more. It also covers the air brake tug test and checks for everything under the hood including alternator, water pump, fuel pump, fluids, and more.

This is a super handy checklist to study anytime you have a few minutes to spare:

Pre-Trip Inspection Checklist - Free Word Document Download (Editable Version)

Pre-Trip Inspection Checklist - Free PDF Download (Print Version)

Pre-Trip Inspection Video By Apex CDL Institute

Jeff from Apex Institute does an in-depth explanation of the entire pre-trip inspection process. This video is loaded with tips that go beyond the CDL test to help drivers really understand how to identify problems.

Pretrip Inspection Self-Test By CDL College

The Pretrip Inspection Self-Test By CDL College is really unique. It's a silent video which will show you the part you're inspecting and then gives you a few seconds to figure out what you should be checking for before giving you the answer. Definitely check this one out. Great for practicing before the CDL exam.

Pre-Trip Inspection Video By Averitt Express

This is a complete back to front pre-trip inspection of a truck and trailer by Averitt mainentance associate Kevin Breeding. This thorough pre-trip inspection covers all inportant points of inside the cab, lights, engine, the tractor itself and the trailer.

We have included two print versions of the pre-trip inspection process from Daniel. The first is the entire pre-trip inspection and the second is an abbreviated checklist for the inspection.

- PDF: Daniel's Pre-trip Inspection (Print Version)

- PDF: Daniel's Pre-trip Inspection Checklist (Print Version)

Why Join Trucking Truth?

- The High Road Training Program

- The High Road Article Series

- The Friendliest Trucker's Forum Ever!

- Email Updates When New Articles Are Posted

Apply For Paid CDL Training Through TruckingTruth

Did you know you can fill out one quick form here on TruckingTruth and apply to several companies at once for paid CDL training? Seriously! The application only takes one minute. You will speak with recruiters today. There is no obligation whatsoever. Learn more and apply here:

- Privacy Policy

- Search search

- ITS Dispatch

- Other Products

Pre-Trip Truck Inspections (11-Step Checklist)

There's a better way to find loads.

Demo the truckstop load board and see how easy it is to find the right loads fast., find your next load, make more money starting now..

The Federal Motor Carrier Safety Administration at the Department of Labor requires a pre-trip inspection by the driver. Any deficiencies must be acknowledged and certified that appropriate repairs have been made before a trip begins.

What is a pre-trip truck inspection?

A pre-trip truck inspection is a thorough check of the truck and its major systems to maintain safety on the road. Inspections need to occur before the start of a driver’s shift and at least once every 24 hours while on the road.

Truck pre-trip inspection needs to be performed by the driver while on duty, but before driving starts.

Why truckers should always perform a pre-trip inspection

Driving a truck is one of the most dangerous occupations, according to the Bureau of Labor Statistics. Drivers of heavy trucks and tractor-trailer trucks suffer fatal accidents more than any other occupation .

A pre-trip inspection checklist helps keep drivers safe. Your inspection is important to ensure safety, maintenance, and procedures are followed to help mitigate liability.

A CLD pre-trip inspection checklist helps uncover potentially dangerous conditions, such as unsecured loads or problems with brakes or steering. While it might be tempting for experienced drivers to skip or shortcut a pre-trip vehicle inspection , it’s never a good idea. “Better safe than sorry” should be the mantra 100% of the time, and drivers shold never skip a thorough pre-trip inspection before a truck hits the road.

Maintenance

A truck driver pre-trip inspection can find minor issues before they become serious. This can save you money on maintenance by solving problems before your trucks get on the road. Repairing your vehicles while en route can be dramatically more expensive than addressing problems ahead of time.

Your DOT pre-trip inspection helps you stay in compliance with Department of Transportation regulations. In the case of an audit, the DOT may review your pre-trip inspection checklist to ensure they have been filled out properly. If the audit shows that issues have been ignored or uncovers a violation, it can lead to fines and hurt your Compliance, Safety, Accountability (CSA) score.

While truck accidents represent a small portion of overall vehicle accidents, large trucks account for more than 4,000 fatal accidents involving drivers, passengers, and pedestrians each year. Even if drivers are not at fault, your liability can increase if you can’t show proof that a pre-trip inspection report was done, was completed improperly, or if known defects were not addressed.

How long should a pre-trip inspection take?

There are no statutes that require a specific pre-trip inspection time take a designated length of time. In practice, an inspection should take as long as necessary to ensure vehicles are safe to drive and have been properly maintained. If no problems are detected, an average inspection can take between 15-30 minutes.

Do not rush inspections. It’s easy to miss things that can put drivers and others at risk.

Pre-trip inspection checklist for truckers

Do you have to log a pre-trip inspection? The answer is yes. Not only are you required to do so by federal law, but you also want the documentation in case of any claims against your company. So, what should a pre-trip inspection checklist include?

Here are some of the most common items:

Inspect the engine compartment.

Inside the engine compartment, check components including:

- Air compressor

- Steering gearbox

- Steering linkage

- Hoses and wiring

Inspect the fuel tank and battery.

Your pre-trip inspection should include a visual check of your fuel tank and battery area to make sure nothing is cracked or leaking. Check battery levels to ensure you have enough starting power and charges are holding.

Inspect the fluids.

Check for fluid leaks by looking under the truck for signs of fluid on the ground, including:

- Power steering fluid

- Brake fluid

- Windshield washer fluid

You will also need to look under the hood to rule out any problems inside the engine compartment. Your pre-trip truck inspection includes checking for adequate fluid levels and the condition of hoses, belts, and wires for safe operation. Pay particular attention to the oil pressure gauge to make sure it’s working properly.

Inspect the brakes.

If your brakes aren’t working optimally, you put drivers and everybody else on the road in danger. A proper pre-trip inspection will include inspecting the brake system both in-cab and externally.

- Truck drivers should check the brake adjustment with the slack adjuster for proper alignment.

- Check brake linings for appropriate thickness.

- Ensure your truck’s air lines aren’t damaged, don’t leak, and are properly sealed.

Brake checks should include air brakes, parking brakes, and hydraulic braking systems.

Inspect the tires.

Inspect tires to make sure you have an acceptable amount of tire tread for safe operation. There should be no cuts, bubbles, or gouges. There should be no foreign objects, such as stones or large debris, between the wheels and no space between tires and rims.

Also, be sure to check and maintain the appropriate air pressure.

Inspect the wheel lug nuts.

Regardless of tire condition, you also need to check the lug nuts. Tighten any loose wheel fasteners. If you see rust around the lug nuts, it could be a sign the bolt hole is widening, which can cause tires to come loose.

Inspect the coupling system.

A failure in the coupling system can cause you to lose your load. Pay particular attention to your kingpin and the sliding fifth wheel locking pin. Then check the other components that connect your trailer to your cab, including:

- Electrical connections

- Locking jaws

- Mounting bolt

- Release arm

Inspect the lights and reflectors.

Exterior lights and reflectors help other drivers see your vehicle approaching and make your rig more visible at night. Check that lights, warning lights, and turn signals are working properly, and lenses are clean for maximum visibility.

Reflectors tend to fade over time from exposure to the elements. Make sure your truck’s reflectors are free of any dirt or debris. They should be intact without cracks, missing pieces, or peeling.

Inspect the trailer.

Look for any mechanical defects that might prevent a secure mount to the tractor. Do a pre-trip truck inspection to look for items such as holes, cracks, breaks, bends, or missing rivets in the:

- Release pins

- Crossmembers

- Release handles

- Locking pins

- Doors and hinges

Inspect the cabin.

Inside the cabin, check seatbelts for any signs of wear or fray and ensure a snug fit. You should also check the operation and functionality of your inside and outside mirrors, seat position, steering wheel, and pedals. Make checking the windshield for cracks or chips standard operating procedure, along with performing a safe start to make sure lights and turn signals are working properly. This includes ABS lights and gauges. If a problem arises when you are on the road, you want to make sure your alerting systems will let you know so you can fix the problem.

You’ll also want to check your windshield wipers and horns.

Inspect the emergency kit.

Trucks are required to carry emergency equipment kits that include:

- Fire extinguishers readily available for use

- At least one spare fuse for each type of fuse needed for parts and accessories

- Warning devices for stopped vehicles, such as bidirectional reflective triangles

- Red warning flags that can be maintained in an upright position

Each item should be in working condition in case of an emergency stop.

Safely haul more high-paying loads.

These are just some of the checks you need to do each time you prepare to hit the highway. Your pre-trip truck inspection checklist should include every aspect of your vehicle and its loads. Ensure you have all the necessary paperwork and documentation to prove the pre-trip inspection was done properly and retain copies for your records.

Once your pre-trip inspection is complete, you’re ready to hit the road and start making money! Find the highest paying loads with the Truckstop Load Board . Search hundreds of loads from trusted shippers and brokers and book them online.

Get a free demo of the load board that delivers more.

- SHARE ON TWITTER

- SHARE ON FACEBOOK

- SHARE ON LINKEDIN

Related Blogs

Personal Conveyance Rules for Owner-Operators

Interstate vs. Intrastate Trucking: Everything You Need to Know

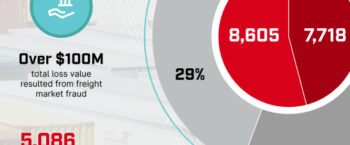

Truckstop’s Fraud Prevention: Leveraging Technology for a Safer Freight Market

Browse by Topic

- Find Freight

- Get Authority

- Improve Carrier Safety

- Manage Business

- Move Freight

- Protect My Business

Schedule a demo.

Find out how our platform gives you the visibility you need to get more done.

Subscribe to our newsletter.

Get helpful content delivered to your inbox.

You did it!

Please provide email address and choose a newslettter option.

Thank you for subscribing! Watch for an email arriving in your inbox soon.

We are sorry, something went wrong. Please try again later.

Get started for just $39

Basic searching and posting on the internet's most trusted load board.

USD/User/Month**

- done Load Searching

- done Truck/Lane Posting

- done Decision Tools

- done Book It Now

Everything you need to start finding and booking loads now.

Everything in Basic plus tools to weed out slow-paying brokers.

USD/User/Month

Level up your profits with tools that make it easy to make more on every load.

** Price per user. Up to 3 users.

* Amount shown excludes applicable fees & taxes.

Tell us about yourself.

Please check that your entries below are correct.

Please check that your entries above are correct.

Recession-proof your trucking business with this FREE guide!

Get the trucker's guide to 2024: how to succeed in any market today.

- Partner Marketplace

- Terms and Conditions

- Partner Marketplace Terms of Use

- Privacy Policy

- Report non-payment

You did it! Thank you for subscribing! Watch for an email arriving in your inbox soon.

Complete pre-trip inspection checklist for truck drivers

By The Schneider Guy

Estimated reading time: 4 minutes

As a truck driver, performing a CDL pre-trip inspection is one of the most common and repeated tasks you will complete. Pre-trip inspections help truck drivers ensure their tractor and trailer are safe to operat e before hitting the road.

Keep reading to learn what a p re -trip inspection is and what should be on a p re -trip inspection checklist .

What is a pre-trip inspection?

A pre-trip inspection includes checking over the tractor and trailer a truck driver will be operating . A pre-trip should be completed before the operation of a vehicle :

- At the beginning of a driver’s shift.

- Any time a new trailer is picked up.

- After a 10-hour break.

A thorough inspection usually takes anywhere from 30 minutes to one hour and should be logged as on-duty, not driving (line 4) .

How to complete a CDL pre-trip inspection

CDL pre-trip inspection checklist

1. passenger-side engine: .

- Air filter housing: Secure mounting, cover in place.

- Windshield washer fluid reservoir: No leaks, proper fluid level.

- Turbocharger: No oil or exhaust leaks.

- Engine air ductwork: No cuts, clamps secured.

- Alternator: Mounting secured, no broken or loose wire.

- Accessory drive belt: Not cracked or frayed.

- Air conditioner compressor: Secure m ounting .

2. Front brakes (covers all five brake components):

- Brake drum: No cracks.

- Brake lining: No cracks or damage.

- Slack adjuster: Proper angle to the brake chamber, clevis and cotter pin intact.

- Brake air line: No bulges or cuts, fitting tight .

- Brake chamber: Mounting bolts secured, band clamp secured.

3. Front wheel:

- Tire: ABCs (abrasions, bulges, cuts), pressure = 120 PSI, tread depth = 4/32 min ( DOT ) .

- Wheel: Not cracked or bent.

- Hub oil: Not leaking, at proper level – if it’s a sealed unit, can’t check level.

- Oil seal (outer): Not leaking.

- Valve cap: Not missing.

- Lug nuts: None missing, no streaks or shiny areas, none loose.

4. Driver side of engine:

- Radiator brace: No cracks or missing bolts.

- Radiator: Not leaking, secure mounting.

- Water pump: No cracks, not loose or leaking.

- Fuel water separator/filter: Not leaking, secure mounting.

- Pitman arm/drag link: Not cracked, castle nut secured with cotter pin.

- Steering gear box: Secure to frame, not leaking.

- Power steering reservoir: Secure mounting , no leaks, proper level.

- Dipstick: Right level, secured after check.

- Steering shaft: Secure, not loose or damaged.

- Fuel pump: No cracks, not loose or damaged.

- Oil filler cap: Secure, no cracks.

- Engine coolant reservoir: No leaks, proper fluid level.

5. Steer axle suspension:

- U-bolts: No cracks, no loose or missing nuts.

- Leak spring: No cracks, not loose or shifting.

- Tie rod: Secured with castle nuts and cotter pins.

- Shock absorber: Secure mounting, not leaking oil.

- Axle: Not cracked.

6. Rear suspension:

- Spring mount: No cracks, secure mounting.

- Tire: ABCs (abrasions, bulges, cuts), pressure = 110 PSI, tread depth = 2/32 min ( DOT ) .

- Airbag (bellows): Fully inflated, secure mounting, not ruptured.

7. Side of cab:

- Mirrors: Secure m ounting , no broken glass.

- Doors: No damage, glass not broken, hinges secured, opens and closes well.

- Lights and turn signals: Working, not cracked.

- Steps: Mounted, secured to skirting.

- Battery box: Secure m ounting , cover latched.

- DEF cap: Cap secured.

- Fuel cap/tank: Gasket in place, vent in place, chain secures the cap to the tank.

- Side skirting: No damage, panels secure.

- Side box: Secured, safety triangles present.

- Side of sleeper berth: No body damage.

- Sleeper berth window: No cracks.

8. Rear of cab:

- Electrical cord: No bare wire, no corrosion, check the plug at the end of the cord.

- Air line: Not tangled or worn, rubber grommets not worn, fittings tight.

- Cab shock absorber: Secure mounting, not leaking oil.

- Cab airbag (bellows): Not ruptured, securely mounted.

9. Driveshaft/rear frame:

- Driveshaft: Not cracked.

- Universal joint: Not cracked, not missing bolts, no shiny areas.

- Differential: Not leaking oil.

- Frame: Straight, no non-factory welds.

10. Fifth wheel area:

- Pivot pin: Keeper pin and cotter key intact.

- Slider lock pins: Fully engaged.

- Release arm: Not bent.

- Slider rail: No broken welds or missing bolts.

- Slider stop blocks: Welds not broken, not missing bolts.

- 5th wheel platform: Well-greased, tilted down.

11. Front of trailer:

- Top rail: No cracks or collision damage.

- Clearance lights: Not broken, working properly.

- Registration: Not missing, readable.

- Document box: Not missing or loose.

- Air line /glad hands: No bulges or cuts in air lines, rubber grommets not damaged on glad hands.

- Electric hook up: No broken pins, cover intact.

- PM sticker: Current, legible.

- Height sticker: Legible, legal for route.

- Placard holder: Not broken or missing rivets.

- Tracking device: No cracks or collision damage.

12. Side of trailer:

- Top rail: Not cracked, no collision damage.

- Clearance light: Not broken, operational.

- Bottom light: Not cracked, no collision damage, no missing bolts.

- Landing gear: Legs straight, no broken welds in bracing, sand pads secured and clean handle in cradle.

- Reflector tape: Clean.

- Side panels: No holes or cuts, no missing rivets.

13. Rear of trailer:

- Latches: Secured, not damaged.

- Lights: Not broken or missing, operational.

- Splash guard: Brackets and guard secured.

- License plate: Secure and clean, light is working.

- Bumper: Not damaged, no broken welds.

- Door hooks: Not loose, no missing bolts.

- Hinges: Not cracked, no missing bolts on both sides.

- Door seals: No separation, no rubber tubing sticking out.

14. Trailer suspension:

- Air line: No bulges or cuts, fittings are tight and not rubbing.

- Axle: Not bent or broken.

- Clevis pin/cotter key: Not missing.

- Slack adjuster: Proper angle, clevis pin and cotter pin intact.

- Brake linings: Minimum of ¼ inch thick, not cracked.

- Brake drum: Not cracked.

- Tire: (ABCs), tread depth = 2/32 , air pressure = 110 PSI.

- Spring: Not broken, not shifted.

- Spring mount: No broken welds.

- U bolts: Not loose, not cracked.

- Torque rod: Secure mounting, bushings intact.

- Spring brake chamber: Secure m ounting , band clamp secure.

15. Gauges/inside the truck:

- Fuel: Matches visual when looking in the tank.

- Def level: Maintain a minimum of one light bar.

- Oil pressure: 25-50 PSI.

- Speedometer: 0-60 MPH.

- Air pressure: 90-120 PSI.

Please note that the list above is just an example. It is important to remember the type of driver you are, the company you work for and the type of truck you drive can impact your CDL pre-trip inspection . Be sure to consult your company guidelines or speak with your leader for more information on your post-trip inspection requirements.

Get more great driving tips and guides.

Schneider Guy loves the "Big Orange." He's passionate about the trucking industry and connecting people to rewarding careers within it. He's been the eyes and ears of our company since our founding in 1935, and he's excited to interact with prospective and current Schneider associates through "A Slice of Orange."

Related posts

8 CDL Road Test tips to help you pass

How hard is it to get a CDL?

How to get your CDL – 7 simple steps for new truck drivers

Join 100,000+ Drivers

- Sponsorship

- Thinking of Becoming a Truck Driver?

- Getting a CDL License

- Trucking Driving Jobs Guide

- Trucking Company Guide

- Trucker Life

- Paid CDL Training

- CDL Schools

- Professional Driving Skills + Knowledge

- Owner Operator

- Latest Articles

- Truck Driver Skills

The Pre-Trip Inspection: A Practical Guide For the Truck Driver

Updated February 24th, 2022

- Facebook 426

- Pinterest 1

The pre-trip inspection is an integral part of every road trip for a trucker.

It’s probably the most disliked and most often overlooked part of the job of the professional truck driver in the trucking industry.

This inspection is meant to be a thorough check of the truck, trailer and load.

The check is to ensure that everything is in correct working order, prior to the truck and driver, departing on a trip.

Any damage or issues found during the pre-trip inspection which needs attention, must be addressed before departure.

CDL Test Pre-Trip Inspection

If you just came through the process of getting your CDL, you can breathe a sigh of relief.

You don’t have to check all 500 or so items that you had to memorize for the test every single day.

Out on the road, a thorough pre trip shouldn’t take more than 10 to 15 minutes.

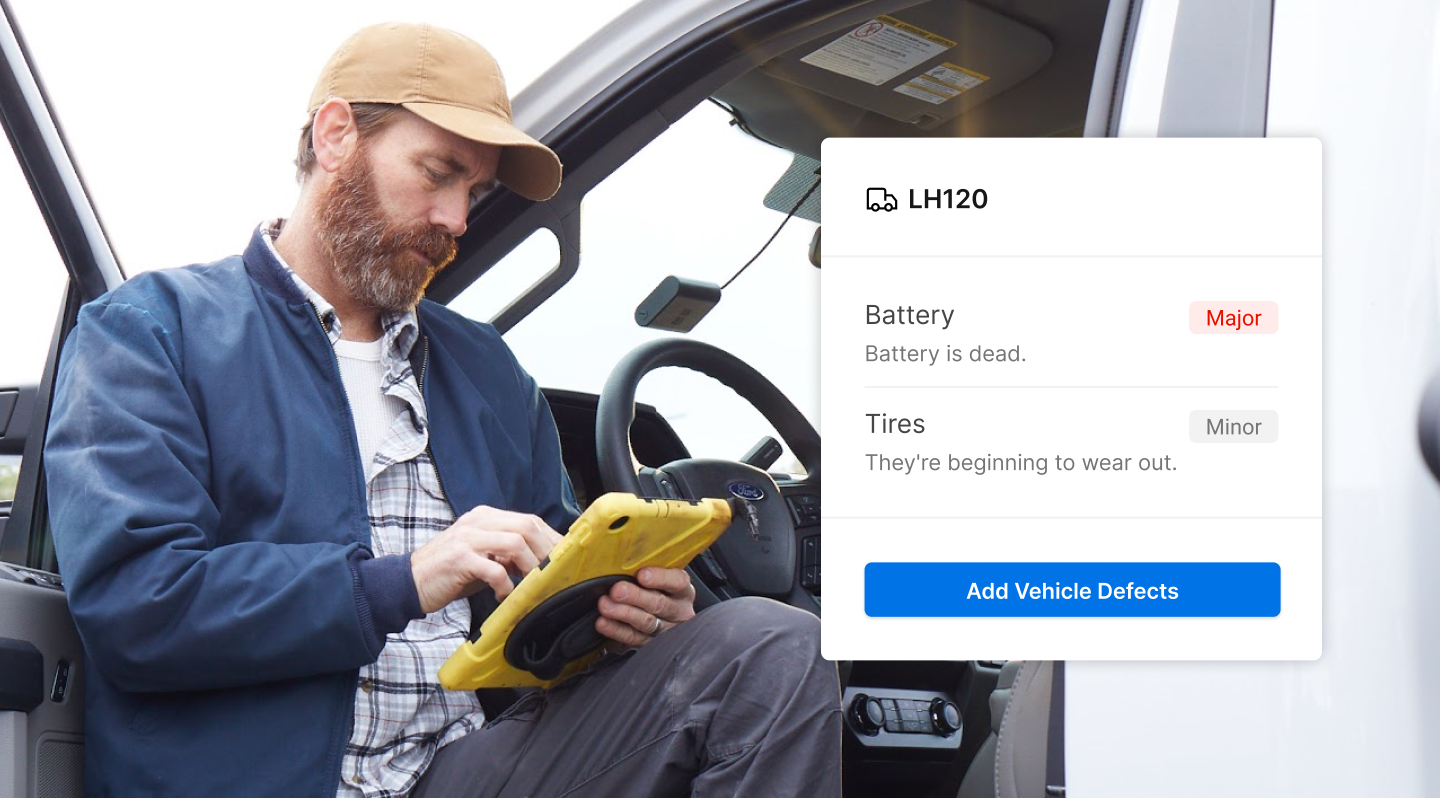

DVIRs – Daily Vehicle Inspection Report

According to federal law ( FMCSR Section 396.11 ), every day, a driver must submit a Daily Vehicle Inspection Report (DVIR) for each power unit he operates. Multiple trailers can go in one report.

DVIRs are either paper or electronic.

Not every trucking company (ahem) enforces this policy, so some truck drivers can go months or years without submitting a DVIR.

Minimum DOT Pre-Trip Inspection Requirements

- Service brakes including trailer brake connections

- Parking brake

- Steering mechanism

- Lighting devices and reflectors

- Windshield wipers

- Rear vision mirrors

- Coupling devices

- Wheels and rims

- Emergency equipment

Your trucking company’s DVIR might be more thorough.

This is a thorough Q&A on DVIRs which you can refer to.

Inspecting a New Truck

When you are assigned a new truck (either daily or just once), there are a few additional things you need to check for on the pre-trip inspection.

Truck Compliance

- Cab card and book – This is a book containing the registration, inspection, permits, cab cards, IFTA paperwork, and any other important papers for the truck. Make sure it is in the truck and all the paperwork is up to date.

- Inspection sticker – This is outside the truck. Find it and make sure the truck is not overdue.

- IFTA stickers – These are the fuel tax compliance stickers. They are on both sides of the truck. Make sure the current year is displayed.

- Elog device – Most trucks are required to have a working elog device.

- Required permits – These are in the cab card book. The most common permits are Heavy Motor Vehicle Trip Permit (Oregon) and the Weight Distance Tax Permit (New Mexico).

- New York HUT sticker – This is usually on the front of your truck. It’s a type of permit.

- License plate – Make sure the license plates on the front and back of the truck match.

- FMCSA Safety Regulations and Hazardous Materials book – These will be given to you by your company. They must stay in your truck within arms reach from the driver’s seat.

- Paper logbook – If your e-log stops working, you must log your hours in a paper logbook, which must be kept in your truck.

- Medical card – You must keep your current medical card in your truck. Always have your CDL on you as well.

- Orange triangles – You must have 3 triangles for when you break down.

- Fire extinguisher – Must be charged and secured to the truck. No rolling around on the floor.

- Extra fuses – If your truck doesn’t use circuit breakers, you must have spare fuses.

- Load bars and/or straps

- Extra oil, coolant, and windshield washer fluid

- Line antifreeze and diesel anti-gel

- Chains and bungees

- Gladhand seals

- Hammer, wrench, wire cutters, cable cutters, knife with glass-breaker

The Class A Pre-Trip Inspection Process

Unless I have to bobtail to pick up my trailer, I inspect my truck and trailer together.

The best way to memorize a thorough pre trip is to do it the same way each time.

Your process will look different from mine, but as long as you are consistent, you will be less likely to miss anything.

I do the inspection first thing each morning as well as every time I swap trailers.

Paperwork and Trailer

- Check the paperwork. It should be the first thing checked when you get to your truck.

- Match the trailer number to your paperwork. If your trailer has a seal, make sure it matches too.

- Unsealed trailer. If your trailer does not have a seal, open it and confirm the product matches the bills. If you are picking up an empty trailer, open it and make sure it’s actually empty.

- Confirm your destination. Ensure the destination is the same as on your trip sheet or load assignment. If there is a discrepancy, call your dispatcher.

I personally like to start with checking under the hood of the rig. Not everyone does, but I do.

Under the Hood of the Truck

I walk around the front of the truck, making sure all the lights work. Then I open the hood.

- Fluid levels – Check all fluids: coolant, oil, power steering fluid, and windshield washer fluid. Make sure caps are tight for the rad, oil filler, power steering fluid and the dip-stick is seated properly.

- Alternator, water pump, power steering pump –Make sure these are in good working order, and the belts are not worn or have too much slack.

- Observe at the engine block. Check for leaks, fluid running down the side of the engine. Check for wear, cracking or fraying. Inspect fan belts for proper tension and signs of wear.

- Hoses – Check all hoses for leaks, cracks, and tears.

- Wiring – Check wiring for wear.

- Steering linkage – Check linkage for worn or missing parts.

- Tires – Tires should be properly inflated and have decent tread. If there are flat spots on the tire, it needs to be replaced.

- Hub seal – Make sure it’s not leaking and wiped with oil if transparent.

- Brakes – Brake chambers should not be out of round and should be free of grease. Shoes should not be worn down too much.

- Slack adjusters – Pull slack adjuster. If it travels more than an inch, it needs to be adjusted.

- Suspension – Shocks should be in good condition, and not covered in grease or oil.

Back of the Truck

Next, I check the back of my truck because it’s easier to check this before hooking to a trailer.

- Tires – Tires should be properly inflated and have decent tread. If the tires have flat spots, the tire needs to be replaced.

- Suspension – Shocks and airbags should be in good condition, and not covered in grease or oil.

- Drive shaft – Driveshaft should be undamaged and free of grease. Make sure there is no debris in the u-joints.

- Frame – The frame should not have any welds and not cracked or significantly rusted.

- Fifth wheel – The fifth wheel should be properly greased and not broken.

- Fuel tanks – Fuel tanks should not be leaking.

- Stairs and catwalk – Stairs and catwalk should be free of debris and not broken.

Tires should be checked with a tire gauge.

Tip . This is especially if you are slip seating. Tire thumpers aren’t very accurate. If you use a tire thumper, still check with a tire gauge from time to time.

Drives and tandems should be inflated to 100-110 psi and have a minimum tread or 2/32in. Steer tires should be inflated to 110-120 psi and have a minimum tread of 4/32in.

Tires under 50 psi should be replaced, as they can’t retain enough air pressure.

Flat spots can occur from dragging tandems in the winter or when trying to slide the tandems. Tires with flat spots should be replaced.

Check tires for damage, nails, and punctures.

Next, I jump in my cab and start my truck.

- Gauges – Make sure air, oil, and water temperature gauges rise to normal levels.

- Mirrors – Adjust mirrors before moving your truck.

- Windshield wipers – Make sure they work and sit flat against the windshield.

- Horn – Make sure the city and air horns both work.

- Heat and A/C – Check to see if heat and/or air conditioning is working.

- Seat belt – Seat belt should not be frayed and should move freely.

Coupling and Air Lines

This is what could happen if you don’t do the tug test.

The pre-trip inspection is a pretty important thing to do.

Learn your pre-trip procedure and do it when required.

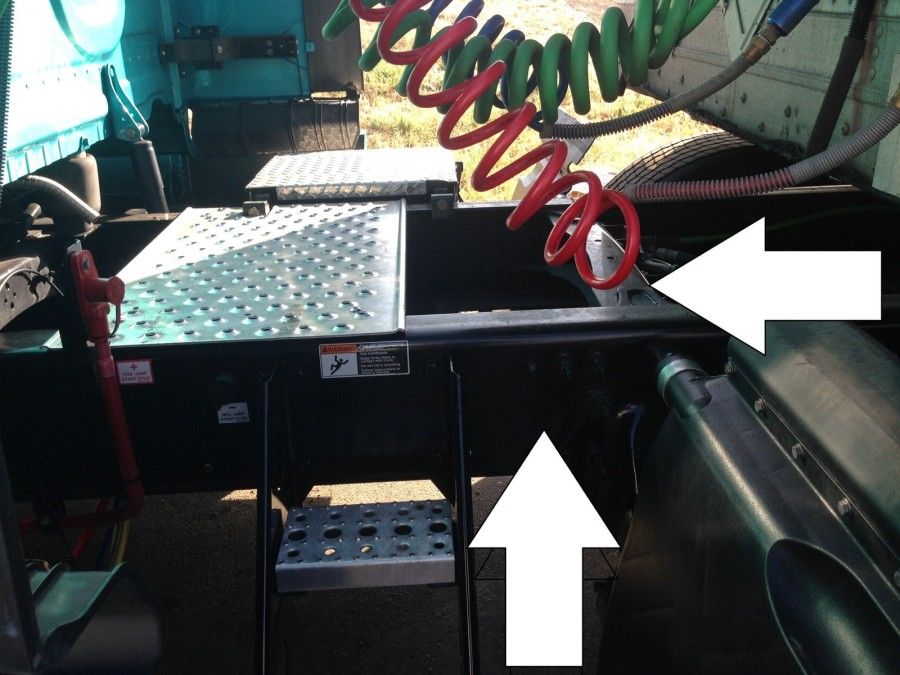

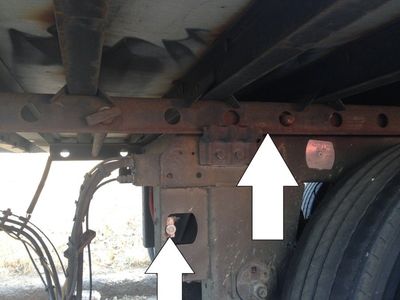

This is why you should always do a tug test when picking up a trailer. The passenger side of the front of the trailer is resting on the frame of the truck and NOT hooked up to the 5th wheel.

The front left corner of the trailer is supported by retracted landing gear only. (Not good!)

The truck driver in this photo (hopefully) learned how critical a pre-trip is. Don’t end up in a pickle like this guy.

Next, I hook up to my trailer.

- Tug test – I back under my trailer until I hear a click, and then immediately do a tug test.

A tug test tests both your coupling and your brakes. If you pull away from your trailer, you aren’t hooked properly.

If you pull your trailer with you, your trailer brakes are out of adjustment. Be absolutely sure to write it up and have it corrected before departure.

- 4 Ways + Headlights. I also turn on my four-way flashers and headlights.

- Airlines and pigtails – Next, hook up airlines and pigtails (electrical connection). Inspect to make sure they aren’t leaking or ripped.

- Visual check of Fifth wheel – Look at the fifth wheel arm under the trailer to make sure it is coupled. The arm should be in.

- Landing gear – Raise the landing gear and check for damage.

Next, I check the bulkhead (front of the trailer).

- Wall – Make sure the wall is not damaged.

- Inspection sticker – Check the DOT inspection sticker to make sure it’s not out of date.

- Registration paperwork – Check the front trailer box to make sure the registration is good.

- Reefer unit – If you are pulling a reefer, select the pre trip function on the unit and run it. It should be completed by the time you are finished your pre trip inspection.

Next step for the pre-trip inspection is to check the side of the trailer and the tandems.

- Lights – Lights should be on and flashing.

- Suspension – springs or airbags should be in good condition, and not covered in oil or grease.

- Tandem pins – Tandem pins should be locked in position, and slider arm should be in its cradle.

- Cables – Make sure the tandem cables aren’t dragging on the ground.

- Underbelly – Make sure there are no damaged beams under the trailer. Check the entire length.

- Mudflaps – Mud flaps should not be torn and hanging.

Back of Trailer

Next, I check the back of the trailer.

- Doors – Doors and hinges should not be damaged.

- Door latches – Doors should be closed and secured.

- Seal – Seal should be intact and match paperwork.

- DOT bumper – DOT bumper should not be damaged

- License plate – Check for the license plate. They tend to wear out and fall off.

Passenger Side

Next, I check the passenger side.

- Brakes – Brake chambers should not be out of round and should be free of grease.

- Suspension – Springs or airbags should be in good condition, and not covered in grease or oil.

- Mudflaps – Mud flaps should not be torn.

Ready to Roll

Finally, I jump in my truck and double check my paperwork and destination.

I release my air brakes, roll forward, and push the service brake.

If everything is good, I’m ready to roll.

Post-Trip Inspection

When I’m done for the day, and every time I swap trailers, I do a post-trip inspection. If I am swapping trailers, I do a pre-trip on the new trailer as well.

A post-trip includes:

- lowering the landing gear

- removing the airlines

- uncoupling, and walking around the trailer checking tires, lights, seal, and mudflaps

Then I finish my paperwork and go home.

Slip Seating

If you slip seat (meaning you are in a different truck each shift), your pre- trip check should be more thorough than if you are permanently assigned a truck.

This also applies to the first inspection after being assigned a truck.

Please be courteous and write up any problems or issues found, so the next driver of the vehicle doesn’t have to deal with it.

Side Note: Clean out your truck and throw away any trash. Common courtesy goes a long way in trucking, between drivers.

Pre-Trip Inspection F.A.Q.

Most breakdowns can be avoided with proper preventative measures, such as daily inspections.

Thorough inspections should be done at the start of each shift. Inspections of trailers should be done every time you swap trailers.

Each driver should do a thorough pre-trip every time they swap drivers.

It should take about 10-15 minutes to perform a pre trip inspection.

The DOT. Make sure you stay in compliance so you don’t end up with hefty fines and an out of service.

The best way to memorize your pre trip inspection routine, is to do it the same way every time. That way you’re less likely to miss something. If you have questions, ask your safety team at your company.

Fluids in the engine, engine hoses and wires, brakes and suspension, mudflaps, trailer registration and inspection paperwork, and license plates.

A Few Trip Planning Tips

- Buy and learn to read a trucker’s atlas. It’s useful to plan routes and avoid restricted roads. I find this road atlas a necessity as a professional truck driver.

- Buy a decent trucking GPS , but don’t rely on it 100%. Use common sense.

- Don’t use the GPS in your elog device. It will put you in a lake.

Please note that minimum requirements for the inspection are established by the FMCSA.

But these may vary by state, trucking company, truck type, and trailer type.

It is your duty as a professional truck driver to perform a thorough pre-trip inspection before each trip and before you drive.

You’ll save yourself from headaches, fines and unnecessary accidents.

More Articles You May Like

- Trucking Terms – A Guide to Our Industry’s Lingo

- The 18 Wheeler – A Comprehensive Guide to Big Rigs

CDL Truck Driver Skills – Tips, Tricks + Knowledge to Kick Your CDL Skills Up a Notch!

- The D.O.T. Physical- A Guide For the Truck Driver

Everything You’ll Want To Know About Paid CDL Training

Learn how to talk cb lingo like a trucker, c’mon.

Best Truck Engines + The Worst Truck Engines: A Trucker’s Guide

What you need to know about owner operator vs company driver jobs, twice a month we email you the best tips and new articles to help you better navigate the trucking industry..

10 Truck Driving Safety Tips Every Professional Driver Should Follow

A veteran 40+ years truck driver shares 10 of the all time, tried and true truck driving safety tips ALL professional truckers should know AND follow! If every driver of EVERY vehicle on the road followed these safety tips, our roads would be SO much safer.

Trucker Tips Master Guide: Expert Advice From Experienced Truck Drivers

A collection of trucker tips from million milers and experienced drivers. These are gold nuggets for the new truck drivers!

Instruction, clear advice, videos and photos for truck driver skills, maneuvers and information for all professional truck drivers.

A practical guide to paid CDL training programs. Recommended Company Sponsored Schools, Requirements, pros + cons, what to expect from company-sponsored cdl training programs.

How Witnessing a Fatal Accident Can Affect You: Forever

Truck driving can be a great career. But like any career, there are downsides and sometimes even a dark side. […]

10 Reasons Why Truck Drivers Quit Their Jobs

In the trucking industry, retaining drivers is a constant challenge for trucking companies. Understanding why truck drivers quit is essential […]

The Big Rush For More Truck Drivers To Put Behind the Wheel

It never ceases to amaze me how many regulations govern and control nearly every move we make as truck drivers. […]

Big Rigs, Bigger Dreams: The Best Heavy Haul Trucking Companies, U.S.

Heavy haul trucking is a specialized sector of the trucking industry. It’s a much more challenging driving job than hauling […]

The Fight Against Criminal Record Bias in the Trucking Industry

Truck driving is more than just a job. It’s a lifeline for our communities, delivering goods and keeping the wheels […]

Follow Smart Trucking

- Maintenance

- Fuel Management

- Safety Management

- Integration

- PM Scheduling

- Daily Operator Reporting

- Audit Checklist Manager

- Other Features

- Popular Posts Top Fleet Management Software Features in 2024 How AI is Transforming Fleet Management Pre-Trip Inspection Checklist for Trucker: A Guides

- Popular Posts Enhancing Safety in Oilfield Operations with HVI APP | CNC Oilfield Enhancing Equipment Uptime and Reducing Downtime with HVI APP at T&T Construction Kal Tire Ditches Paper Based Vehicle Inspections, Saves Time with HVI Mobile App

- Construction

- Transportation

- Agriculture

- Waste Management

- Oil & Gas

- Popular posts John Deere Tractor Checklist: Ensuring Optimal Performance and Operator Safety Tipper Maintenance and Inspection Checklist Comprehensive Safety Management Checklist | HVI App

- Popular posts How to Choose the Best Fleet Management Software for Your Business Fleet Maintenance and Telematics Software: Simplified Guide Hanson Boosts Construction Safety and Compliance with HVI App

- Learning Video

- Learning Document

- Partner With Us

- HVI Community Join the discussion with fellow members.

- HVI Help Center Get best practices, helpful videos, and training tools

- Popular posts How to Choose the Best Fleet Management Software for Your Business Six New Features in HVI to Improve Safety Management Crusher-Safety-Checklist| HVI APP

- Popular posts Enhance Fleet Efficiency How HVI and Geotab Integration Streamline Vehicle Inspections Electronic Logbook: Streamlining Fleet Operations for Enhanced Compliance and Efficiency RKD:Enhancing Visibility and Profitability with the Logbook Feature in CMMS Software

- Caterpillar

Pre-Trip Inspection Checklist for Trucker: A Comprehensive Guides

The pre-trip inspection checklist is a crucial part of a trucker's daily routine. It ensures that the vehicle is safe and road-ready, helping to prevent accidents and breakdowns. For truck drivers and fleet managers, understanding and implementing a thorough pre-trip inspection checklist is essential for maintaining vehicle safety, complying with DOT standards, and ensuring smooth operations. In this comprehensive guide, we will cover all aspects of the pre-trip inspection process, providing step-by-step instructions, tips, and best practices for truckers.

What is a Pre-Trip Inspection?

A pre-trip inspection is a systematic check of a commercial truck's components and systems before hitting the road. It involves examining various parts of the truck to ensure they are in proper working order. This inspection is mandated by the Department of Transportation (DOT) and is crucial for truck driver safety. The pre-trip inspection checklist typically includes checking the brakes, lights, tires, steering, and other vital components.

Why is a Pre-Trip Inspection Important?

Conducting a pre-trip inspection is important for several reasons:

- Safety: Ensures that the truck is in safe operating condition, reducing the risk of accidents.

- Compliance: Meets DOT regulations and avoids potential fines or penalties.

- Maintenance: Identifies potential issues early, preventing costly repairs and downtime.

- Efficiency: Helps maintain efficient operations by ensuring the truck is road-ready.

Primary Benefits of a Pre-Trip Inspection Checklist

A comprehensive pre-trip inspection checklist offers numerous benefits:

- Accident Prevention: Regular inspections help detect issues that could lead to accidents.

- Cost Savings: Identifying and fixing problems early can save on expensive repairs.

- Legal Compliance: Staying compliant with DOT regulations helps avoid fines and legal issues.

- Improved Reliability: Ensures that trucks are reliable and less likely to experience breakdowns.

- Enhanced Reputation: Consistently well-maintained trucks contribute to a positive reputation for safety and reliability.

Common Issues Found During Pre-Trip Inspections

During pre-trip inspections, truckers often encounter common issues such as:

- Worn Tires: Tires with low tread depth or damage can pose significant safety risks.

- Brake Problems: Faulty or worn brakes can lead to dangerous driving conditions.

- Fluid Leaks: Leaks in oil, coolant, or other fluids can indicate underlying mechanical problems.

- Electrical Issues: Non-functioning lights and reflectors can reduce visibility and increase the risk of accidents.

- Loose or Damaged Components: Parts like belts, hoses, and mirrors that are loose or damaged can impact vehicle performance and safety.

Next Steps for Implementing a Pre-Trip Inspection Checklist

To effectively implement a pre-trip inspection checklist, follow these steps:

- Standardize the Checklist: Develop a standardized checklist that covers all critical components and systems.

- Train Drivers: Provide training to ensure that all drivers understand the importance of pre-trip inspections and know how to perform them correctly.

- Use Digital Tools: Consider using digital inspection tools to streamline the process and ensure consistency.

- Document Inspections: Keep thorough records of all inspections and any issues found to track trends and address recurring problems.

- Regularly Review and Update: Regularly review and update the checklist to reflect any changes in regulations or best practices.

By implementing a comprehensive pre-trip inspection checklist, truckers and fleet managers can ensure their vehicles are safe, compliant, and road-ready, ultimately enhancing safety, efficiency, and reliability.

A thorough pre-trip inspection checklist is vital for ensuring truck driver safety, compliance with DOT standards, and maintaining vehicle efficiency. By following the steps outlined in this guide, truckers and fleet managers can effectively conduct pre-trip inspections, identify potential issues early, and ensure their vehicles are road-ready. Implementing a comprehensive pre-trip inspection process not only enhances safety but also helps prevent costly breakdowns and delays. Start using our pre-trip inspection checklist today to ensure your truck's safety and compliance.

For more tips and detailed guides on truck maintenance and safety, visit our blog regularly.

Contact Us for More Information

Top 10 FAQs: Pre-trip Inspection for Trucks

What is a pre-trip inspection checklist.

A pre-trip inspection checklist is a systematic guide used by truck drivers to ensure their vehicle is safe and ready for the road.

Why is a pre-trip inspection important for truckers?

It ensures the safety of the driver and others on the road, helps comply with DOT regulations, and prevents breakdowns and costly repairs.

What should be included in a pre-trip inspection?

The checklist should include checks for brakes, lights, tires, steering, fluid levels, and emergency equipment.

How often should a pre-trip inspection be performed?

A pre-trip inspection should be performed before the start of each trip.

What are the benefits of using a pre-trip inspection checklist?

Benefits include improved safety, compliance with regulations, early detection of issues, and reduced maintenance costs.

Is a pre-trip inspection mandatory?

Yes, the DOT mandates pre-trip inspections for commercial vehicles to ensure road safety.

Can a pre-trip inspection help in reducing vehicle downtime?

Yes, identifying issues early can prevent breakdowns and reduce downtime.

What should I do if I find an issue during a pre-trip inspection?

Document the issue and report it to your fleet manager or maintenance team for immediate attention.

Are there digital tools available for pre-trip inspections?

Yes, there are various apps and software solutions that can help streamline the inspection process.

How can fleet managers ensure drivers are performing pre-trip inspections correctly?

Implementing a standardized checklist, providing training, and using digital inspection tools can help ensure consistency and accuracy.

We’ve created a comprehensive pre-trip inspection checklist for you. If you don’t have DOT compliance software , you can just save this checklist and use it during your daily inspections.

Download HVI Fleet App Today

Keeping safety as the top priority in your fleet business ensures smooth operations

- June 6, 2024

- By Harry Christ

GET MOBILE APP ON YOUR DEVICE TODAY

Latest Posts

Share This Story, Choose Your Platform!

Don't leave empty handed, get free demo about hvi fleet management software for inspect and maintain your fleet and vehicle with ease.

Complete CDL Pre-Trip Inspection Checklists for Class A and Class B Drivers

Your fleet is loaded, and the fuel tanks are full – you’re ready to move. Or are you?

If you haven’t completed a pre-trip inspection checklist, you might not be.

The Department of Transportation (DOT) requires all drivers holding a commercial driver’s license (CDL) to complete a pre-trip DOT inspection checklist before operating a commercial vehicle. Usually taking about 10-15 minutes, this inspection checks essential systems such as brakes and steering, as well as tires, mirrors, and emergency equipment.

So how can drivers know what to check? In this article, we’ll run down the DOT requirements for pre-trip inspection checklists, along with key differences between Class A and Class B inspections and even some useful tools that can help make the job easier.

What is a pre-trip inspection checklist?

A pre-trip inspection checklist is a list of items that CDL holders need to review before operating their vehicles. As you may have guessed, this process is known as a pre-trip inspection .

What is a pre-trip inspection?

Pre-trip inspections aren’t just an annoying routine – they’re an important and necessary safety measure that helps ensure that commercial vehicles are up to fleet safety operation standards .

While the scope and contents of a pre-trip inspection checklist vary according to the type of commercial vehicle and its use, you can complete most inspections in about 10-15 minutes. Checklist items generally include assessing the operational condition of anything the driver and vehicle need to operate the vehicle safely . This usually includes things like an air brake check, along with checking lights, tire pressure, couplings, and so on.

Drivers must also record their inspection results in a driver vehicle inspection report (DVIR), which is usually automated (or at least streamlined) in companies with established fleet management tools. Periodic inspection requirements require additional pre-trip inspections every 24 hours of continuous use or whenever the driver changes vehicles.

It may seem like a lot to review, but most of it boils down to common sense. Before you start crawling under the nearest truck, however, you may want to see whether you have to perform a pre-trip inspection in the first place!

Who needs to complete a pre-trip inspection?

Pre-trip inspections are mandatory for both Class A and Class B commercial driver’s license (CDL) holders.

If you’re a CDL holder, you probably already know which Class you fall into. But just in case, here’s a quick refresher on the types and weights of vehicles that different classes of CDL holders can operate.

- The Class A CDL applies to commercial vehicles weighing at least 26,001 pounds that can tow at least 10,000 pounds. This usually encompasses most towing commercial vehicles such as big rigs, tractor-trailers , and flatbeds.

- The Class B CDL applies to commercial vehicles weighing at least 26,001 pounds that can tow no more than 10,000 pounds. This usually encompasses most non-towing commercial vehicles, such as passenger buses, garbage trucks, and delivery trucks.

While there is also a Class C CDL, this usually extends to specialty vehicles not found under either Class A or Class B (such as hazardous waste transport). However, since their detailed inspection procedures are highly specific and beyond the scope of this article, we won’t cover them here.

But what’s involved in Class A and Class B inspections, and how can they differ?

Class A vs. Class B pre-trip inspections

While Class A and Class B vehicles share many of the same detailed inspection procedures (every commercial vehicle has brake lights, after all), each class and vehicle type has its own inspection procedures.

- Class A and Class B commercial vehicles share many common inspection items, such as front and rear suspension, brake lights, minimum brake pad thickness, oil level, etc. These are usually items that apply to any type of road vehicle.

- Class A inspection items are usually those related to towing systems in commercial vehicles, such as the trailer parking brake, coupling areas, etc. These inspection standards usually extend to the trailer, flatbed, or any other object that the truck is towing.

- Class B inspection items are usually those related to non-towing commercial vehicles. As this is a very broad category, some Class B vehicles may not require any additional inspections, while others may have several specific systems to inspect. In the case of the latter, these are usually items specific to the vehicle itself, such as checking for broken seat frames in passenger areas of a bus.

Of course, there’s much more to each pre-trip vehicle inspection than the handful of key differences we’ve listed here. In the next section, we’ll run down the pre-trip inspection process that applies to nearly every commercial vehicle and then detail more class-specific motor vehicle safety inspections.

CDL pre-trip inspection checklist

The standard CDL pre-trip DOT inspection checklist includes everything a commercial motor vehicle needs to navigate the road safely.

These are generally suspension- and engine-related items that would just as well apply to a regular car. As a general rule, a commercial pre-trip inspection test almost always includes the following motor vehicle safety inspections.

Brake system

There’s nothing more important than your vehicle’s air brakes. Note that the following air brake tests apply to both tractor brakes and trailer brakes on Class A commercial vehicles.

- Brake linings and brake pads: Brake pads should be no less than the minimum thickness of one-quarter inch (¼”). Also, be sure to check linings for oil and debris.

- Brake chamber: The brake chamber should be completely sealed with no audible air leaks.

- Air brake hose: No air should leak from the brake hose, and the line should be properly mounted and free of cuts or splits.

- Brake drum: Should not be blue from excessive heat.

- Hand brake: Push rods should have no more than one inch (1”) of play in either direction and stand up 90 degrees when pulled.

Depending on the vehicle, these items are usually checked with a 9-step, 7-step, or 5-step brake test. These tests usually involve pressing the brake pedal, service brake, hand brake, or foot brake under various conditions and seeing whether air pressure recovers to the proper level in time (see your vehicle’s operating guide).

For example, drivers can check for low air pressure by pressing the brake pedal to fan off the pressure. If repeatedly pressing the brake pedal results in a low pressure buzzer or light indicator, the brake system will require repair.

Engine compartment

Engine compartment inspection items include:

- Fluids: The coolant hose, power steering hose, and any tanks or reservoirs should all be securely mounted and have no leaks. Similarly, a dipstick should indicate that all fluid levels (including oil level and coolant level) are at their proper levels.

- Belts: All belts for compressors, pumps, and alternators should have no cracks or frays and give no more than one-half of an inch (½”) of play.

- Air compressor: Should be securely mounted and functional with no cracks or leaks.

- Water pump: Pump hoses must be properly connected with no leaks.

- Alternator: Wires and belts must be properly connected.

Front of vehicle

Front-of-vehicle inspection items usually include steering equipment such as:

- Steering column or steering shaft: The steering column should be straight and unbroken.

- Steering box: The steering gearbox should be intact, and all connected hoses should be securely mounted with no power steering fluid leaks.

- Tie rod and control arms: Both should be straight.

- Drag link: The rubber should be greased and uncracked.

- Pitman arm: All cotter pins and caste nuts are present, secure, and tight.

Front suspension

Front suspension inspection items include springs, spring mounts, shocks, and suspension airbags.

- Spring mounts and spring hangers: Spring mounts should hold spring hangers securely in place with no signs of wear, cracks, or breakage.

- Leaf springs: Should be secured to hangers with no cracks or breakage.

- Shock absorbers: Should have no leaks, splits, or dry rot in the rubber. Leaks are typically located where the top and bottom pieces overlap.

- U-bolts: Should all be securely fastened around the spring and axle.

Rear of vehicle

The rear of tractor or truck inspection items include the following.

- Driveshaft: Should be straight with unbroken U-joints.

- Exhaust: Should be free of rust with no leaks or excessive soot.

- Frame: Structurally sound with no damages or unauthorized repairs/welds.

- Steps: Structurally sound and mounted properly.

- Mud Flaps: Should be clean, unbroken, and secured at the right height.

Wheels and tires

Wheel and tire inspections check for both proper inflation and overall tire condition, specifically tread depth. Note that this also extends to trailers on Class A vehicles.

- Drive and steer tires: Tire tread should be even with a minimum tread depth of 2/32” on drive tires and a minimum tread depth of 4/32” on steering axle tires. Use an air pressure gauge to check inflation levels against manufacturer inflation levels. Treads and sidewalls should be free of cracks, bulges, and abrasions.

- Wheel rims: No unauthorized repairs or illegal welds.

- Hub seal and axle seals: Should show the axle and hub seal intact with no visible leaks or play.

- Dual spacing: Any dual tires must have enough spacing between them.

- Lug bolt holes: All lug bolt holes should have all lug bolts and lug nuts.

- Valve stem: No audible air leaks.

Lights and reflectors

Light and reflector inspections include everything from running lights to DOT tape and 4-way emergency flashers.

- High and low beams: Ensure both are functional on all forward lights.

- Turn signals: Make sure all are functional for both tractor and trailer.

- Brake lights: Make sure all are functional for both tractor and trailer.

- Running lights and license plate lights: Walk around the truck and make sure all are on.

- 4-way emergency flasher function: Walk around the truck to make sure the 4-way flasher rear and front lights are fully operational.

- Reflector tape and DOT tape: All DOT tape and reflector tape should be clean with no signs of excessive wear.

Driver door and fuel tanks

Cab doors and fuel tanks are often located in the same area on commercial vehicles. Be sure to check the following:

- Door and door hinges: Should be intact and latch completely. The rubber door seal should be clean and uncracked.

- External mirrors and mirror brackets: All external mirrors should be firmly attached to their mirror brackets. External mirrors should also be clean and uncracked. Also, be sure to adjust external mirrors and mirror brackets to provide an adequate rear view.

- Steps: Should be securely mounted and able to support the weight.

- Fuel tank: No leaks, with cap and seal unbroken and intact.

In-cab items

Cab inspection usually covers the following items:

- Steering wheel: Fully attached to steering column.

- Gauges: Check that air gauges, oil pressure gauges, and any other gauges for operation function normally within their operating range. Air pressure gauges should build pressure to the governor cut out during an applied pressure test.

- Warning lights: Lights should show clearly for any lighting indicators, such as ABS lights or oil pressure indicators.

- Windshield: Cracks beyond one inch (1”) are not permitted. Windshield wipers should be clean and work properly, and the truck should have enough windshield washer fluid.

- Seat belt: Should fasten securely.

- City horn and air horns: Both air and city horn should sound properly.

- Heater and defroster: Should heat and function properly.

Special checks for Class A and Class B inspections

As we mentioned earlier, a Class A pre-trip truck inspection will usually have different periodic inspection requirements than, say, a Class B pre-trip school bus inspection.

While periodic inspection requirements ultimately come down to the exact type of vehicle (a Class B garbage truck, for example, may require additional inspections for its armature and compactor), the main differences usually come down to trailers vs. passenger areas .

- Trailers share many of the same inspection checklist items as the tractor, specifically the wheels and tires, suspension, and rear of trailer lights and reflectors. Also, make sure that the landing gear is not broken and can be fully raised.

- Coupling area inspections include checking air connectors, electrical lines, and nearby glad hands. All mounting equipment, such as the fifth-wheel plate, kingpin, mounting bolts, skid plate, release arm, and locking jaw and pins, should be present, secure, and in good condition.

- Rear of truck suspension inspections share many of the same items as those of front inspections but with special attention paid to the torque arm (or radius rod), which should be mounted securely with intact brushings.

- Passenger items such as seating, passenger doors, and any wheelchair lifts should all be secure and in working order. Emergency exits should also be clearly labeled and sound an alarm when opened.

- School bus items include all of the passenger items listed above, with the addition of checking student loading lights, stop arm, student rear-view mirror, and a recent first aid and body fluid cleanup kit.

Pre-trip inspections made easy with CalAmp

With fleet management software from CalAmp, you can spend less time filling out pre-trip inspection reports and more time on the road. Request a demo today to see just how easy it is to use CalAmp’s pre-trip inspection tools!

Recent Related Stories

Connect with us.

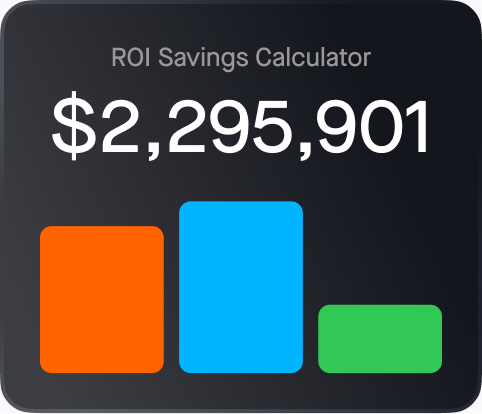

How much will you save with Motive?

Improve your bottom line with Motive’s cutting-edge technology that enhances safety, boosts productivity, and drives profitability.

By industry

Cascade improves safety by 50%, reclaims ~10K hours per year.

With the Motive platform, Cascade has a consolidated view of fleet and spend management across its fleet of more than 3,000 vehicles.

Technical resources

G2 Fleet Management Leader.

Motive ranks #1 in G2 Fleet Management for enterprises; 20% higher than nearest competitor.

Get to know Motive

Missed the Motive Innovation Summit?

Explore the future of logistics and transportation, alongside groundbreaking AI models revealed at our inaugural Summit – Vision 24’.

Talk to Sales or Support 24/7

+1 855-511-3529 Visit Help Center

- Blog »

- Tips for drivers

CDL pre-trip inspection checklist.

A commercial driver’s license (CDL) can put you behind the wheel of a tractor-trailer, a flatbed, or a tanker, among other non-passenger vehicles. Before you hit the road though, you’ll need to complete a CDL pre-trip inspection checklist. By inspecting the commercial vehicle beforehand, you can head out on your route knowing you’ve confirmed major systems and parts are road ready. Recognizing road safety is always a fleet priority . This article provides a comprehensive guide to the CDL pre-trip inspection checklist.

What is a CDL pre-trip inspection checklist?

A CDL pre-trip inspection checklist systemizes the driver’s vehicle inspection to ensure care and consistency. While a pre-trip inspection would be a best practice no matter what, the Federal Motor Carrier Safety Administration (FMCSA) requires these checks for commercial vehicles. Part 396.3 (a) calls on every motor carrier to “systematically inspect, repair, and maintain, or cause to be systematically inspected, repaired, and maintained, all motor vehicles subject to its control.”

The fleet also has to keep formal records of their vehicle checks. So, drivers typically follow a CDL pre-trip checklist and record their findings in the driver vehicle inspection report, or DVIR , confirming the commercial motor vehicle (CMV) inspection is complete.

A CDL A pre-trip inspection checklist requires drivers to inspect many different parts and system including:

- Vehicle lights

- Tires, wheels, and rims

- Windshield wipers

- Emergency equipment

Different motor carriers may add their own expectations to the CDL pre-trip checklist. But they would be adding particular items to check, not doing away with the pre-trip inspection. After all, non-compliance with the federal pre-trip inspection requirements can earn hefty fines and lead to the loss of certifications and licenses.

The Class A CDL pre-trip inspection checklist is important enough that drivers testing for their license are expected to do the pre-trip inspection as part of their examination. Inspection requirements can vary by state. There’s also a Class B CDL pre-trip inspection list.

Why is the CDL pre-trip inspection checklist important?

Compliance isn’t the only reason following the CDL pre-trip inspection checklist is important. The federal requirement is in place, after all, to ensure commercial vehicles on the road are safe to drive.

With continued investment into critical infrastructure over the last 20 years, the percentage of roads in good condition has climbed since 2000. Yet the United States still has hazardous roads. In fact, “from 2000 to 2020, the share of major roadways in poor condition has remained fairly steady, rising from 11.8% to 13.8% over the course of 20 years.”

This makes keeping commercial vehicles in top shape all the more important to safety and efficiency. A CDL pre-trip checklist helps improve fleet safety by avoiding drivers going out on the road in vehicles that are not fit for duty. Taking a truck out on the road with an unsecured load, damaged brakes, disconnected wiring, or another issue could lead to drivers hurting themselves or somebody else.

Fleet vehicle inspections can also help keep drivers on the road. Identifying issues in advance can help avoid major problems that mean downtime and costly repairs. Plus, if the Department of Transportation (DOT) inspects the vehicle and finds something that the driver missed, they can put that vehicle out of service for longer. DOT violations can also lead to fines and hurt your CSA scores . A decrease in your CSA scores can lose your fleet business and cause your insurance premiums to go up too.

How to perform a CDL pre-trip inspection