The Shipyard

For Those Who Love Ships

- Cruise Ships

How Cruise Ships Work (Part 3): The Bridge and the Engine Room

It’s like back in the days when we were little children. Grandpaw’s almost mystical tool shed was strictly off limits, but we were just dying to have a peek, weren’t we? Now that we are all grown up, Grandpaw’s gadgets are old news, but there is still a place or two on a cruise ship that remains like a pie in the sky for all of us obsessed by ships.

It’s the heart of the matter, it’s where it all happens, it’s the real deal. And if you are anything like me, you would gladly give away a day at the spa, a dessert buffet and even two, or the latest Marvel flick in the movie theater, just to spend a precious hour down in the noisy engine room of your favorite cruise ship. But life being proverbially unfair, modern cruise lines rarely allow their passengers to enter the bridge or the engine rooms of their ships, unless the visit is part of a specially organized guided tour. Some cruise ships have a window from which passengers can observe what’s going on in the bridge, but only if they promise not to disturb the officers. Which is really hard, when you badly want to touch everything…

So until the next time someone lets me out of sight and I make my umptieth attempt at trespassing to the engine room, let’s have a quick virtual tour of a cruise ship’s most forbidden and exciting parts.

The bridge is the brain of the ship. It is from there that the captain and his officers command and maneuver the ship, keep watch for other vessels or potential hazards, and navigate through the oceans.

For twenty-four hours each day, the bridge is occupied by two Deck Officers and two Able Seamen, traditionally in four-hour shifts. The main job of the Officer of the Watch is to monitor the ship’s systems and surroundings, and to ensure that everything is running safely and smoothly. During extreme weather, docking, or other special cases, the Captain of the ship is also present on the bridge to guide the deck officers.

The term “bridge” comes from the time of the paddle steamers, where a bridge was built above the two paddle houses that used to hold the paddle wheels. This way the skipper could observe both wheels, while moving freely between the two and giving out commands. On today’s cruise ships, the bridge is usually on the upper deck in the forward part of the ship and extends over the sides of the superstructure, allowing deck officers a view to the sides of the ship as well as down to the waterline. The side extensions are called bridge wings and often have a glass flooring for better visibility.

The bridge houses a number of important nautical devices and information systems for command and navigation of the ship.

Satellite Navigation

The signals emitted by special navigation satellites are picked up by the cruise ship through a special antenna. On board, a computer converts these signals into the exact position of the ship at a given time. On large ships, the position indicator is constantly recorded in a so-called electronic nautical chart.

Satellites also enable automatic positioning systems on modern cruise ships. The positioning system is controlled from the bridge and it uses GPS to ensure that the ship stays at a defined location. When the captain defines a position where the ship needs to remain for a while without anchoring, the system automatically maintains the ship in position by using the bow and stern thrusters.

Modern cruise ships carry a gyro compass and a magnetic compass. The gyro compass consists of a fast-rotating disk, usually positioned in a gimbal. It is a non-magnetic compass oriented parallel to the axis of rotation of the earth and thus indicates the north-south direction.

The gyro compass is more accurate and reliable than the magnetic compass and is therefore the primary reference point for steering the ship. The magnetic compass on board is more prone to inaccuracies and it serves only as back-up.

The word radar stands for Radio Detection And Ranging. Radars are devices that allow us to locate distant objects from a given location, regardless of visibility and weather conditions. The radar emits electromagnetic waves to an object, then receives back the reflected echoes from that object, and interprets them based on distances and angles. These interpretations enable us to determine where an object lies, and in some cases even what its contours look like. In the shipping industry, radars are used for monitoring traffic in ports and coastal regions, for collision protection, for collecting weather data, and for navigation.

Speed logs are devices that measure the speed of the ship. There are two main types of speed logs: Doppler logs and electromagnetic logs.

The Doppler logs send out underwater sound signals. When the sound wave reaches the sea floor, it gets reflected and then returns to the receiver of the log. Due to the movement of the ship relative to the seabed, a Doppler effect occurs and is evaluated by the device. As long as the sound waves can reach the bottom of the sea and return to the receiver, the Doppler log measures the distance travelled over ground. However, if it is no longer possible to use the seabed as a reference, the device uses particles suspended in the water, such as plankton and minerals, to measure travel through the water.

The electromagnetic logs create an electromagnetic field in the water around the ship, with the aid of a small alternating current and a transducer. A voltage proportional to the speed of the ship is generated in the water and is picked up by special sensors, which then transfer the information to an electronic device for interpretation. From the electronic device, the speed is then transmitted onto the displays in the bridge.

Echo Sounder

Cruise ships also have an echo sounder, a device used for the electro-acoustic measurement of water depths (sounding). The depth is determined by measuring the time between the emission of a sound impulse (water sound) and the arrival of the sound waves reflected from the bottom of the sea. The main purpose of echo sounders in cruise ships is safe navigation through waters.

Electronic Chart Display and Information System

The Electronic Chart Display and Information System (ECDIS) is a console, built into the bridge of modern cruise ships, which incorporates the main engine safety system, fire control system, monitoring and control system, power management system, propulsion control system and navigation and maneuvering system. The ECDIS allows for navigation of the ship without the need of traditional paper charts. Navigation can be done manually, automatically, or through the Navigation and Command System (NACOS).

The NACOS is the main software used to coordinate all factors that need to be taken into consideration, in order to navigate and maneuver the ship safely. The console is composed of a number of displays showing information from the radars and compasses, data about the course of the ship and planned maneuvers, the current status of the pitch of the thrusters, the speed of the ship, and anything else concerning the steering of the ship. An intelligent autopilot tracks changes in the behavior of the ship through navigational sensors. If the ship drifts off its course due to strong winds, for example, the system automatically responds to correct the change by sending signals straight to the engine room. Once the signal is received by the engines, the rudder or thrusters of the ship are activated and move to the position given by the system. The displays on the bridge show both the angle of the rudder or thrusters, as well as the rate and the radius of the maneuver in progress.

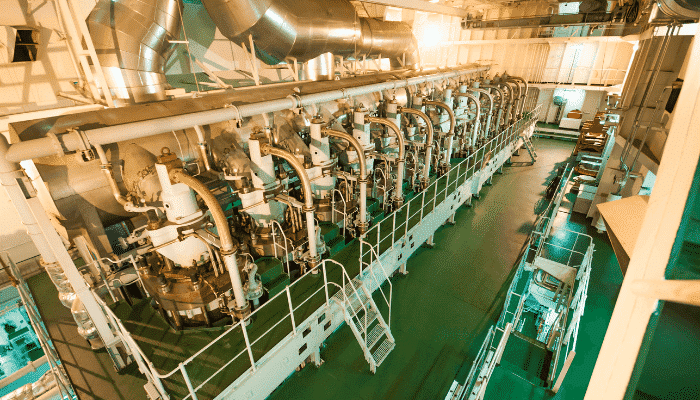

The Engine Room

The engine room is the heart of a cruise ship. It is here that pistons hammer and crankshafts turn to propel the ship forward. It is the loud and oily place where the Chief Engineer and his team work around the clock to ensure that everything is running smoothly. It is the engine room of the ship that allows for the luxuries of air-conditioning, electricity, and plumbing on board cruise ships.

In future articles we will have the chance to explore the contents of the engine room in all the excruciating detail that they deserve, so to all the techies out there – I’ve got you covered. Just stay tuned.

Most larger ships have more than one engine room to house their machinery. The arrangement of the engine room can vary depending on the type, design, and size of the ship. For stability reasons, the engine machinery is typically placed as low as possible in the ship’s bowels and often takes up several decks in height. The machine rooms are split into watertight compartments, each housing different machinery.

Today’s cruise ships operate on diesel or diesel-electric engines. Their operating principle does not differ much from the old days of coal steamers, except for the medium used to generate power. While back in the day ocean liners used steam to move the engine’s pistons, modern cruise ships use diesel fuel. Today’s diesel engines are composed of the engine unit itself, gearboxes, shafts and generators. Some ships also have shaft generators which create electricity from the turning movement of the propeller shaft. The electricity is then used in the cabins, on deck and in the kitchens.

The latest generation of cruise ships are equipped with diesel electric engines. Instead of the more traditional engine-shaft-propeller arrangement, in this case the engines are connected to generators to create electricity. The generators power electric motors, and the electric motors move the propellers.

Aside from the engines and generators, the machinery that occupies the engine rooms includes pumps and heat exchangers for engine cooling, stabilizer fins and their motors, as well as the ship’s bow thruster system.

Since all of the equipment in the engine room is highly dependent on electricity, modern cruise ships also have back-up generators, usually located outside the main engine room, to protect them in case of fire. While these generators cannot produce enough power to keep the ship moving, they produce enough to keep some of the vital functions of the ship running, such as powering the emergency lights and the communication and navigation systems. In case the back-up generators fail, cruise ships are also equipped with a back-up battery that allows some of these functions to continue running for short periods of time.

All the machinery in the engine rooms is monitored in the Engine Control Room (ECR). The ECR is a room full of screens, lights, alarms, and switches from where the current operational status of every piece of equipment can be checked.

The main switchboard of the ECR is used to distribute the generated electricity to where it is needed on board. The ERC is also where the engineering team comes together to discuss and plan the safe running of the engine rooms, to take decisions in emergency situations, to consult the technical manuals and drawings of the ship, to restart certain pieces of machinery if necessary, and to maintain communication with the bridge. Communication between the ECR and the bridge is crucial for the safe operation of the ship, especially during docking, moving through shallow waters, maneuvering, and changes in the course or speed of the ship.

This concludes our three-part overview of how a cruise ship functions. Now that we have covered the basics, in future articles we can explore all the specifics to our hearts’ content. As always, don’t hesitate to leave your constructive comments below and feel free to suggest topics you want to know more about – chances are I want to know more about them too!

Stay in touch and I’ll see you next time!

Share this:

Leave a reply cancel reply.

Your email address will not be published. Required fields are marked *

Privacy Overview

- CruiseMapper

- Cruise news

- Cruise Industry

- How are Cruise Ships Built? Discover the Construction...

How are Cruise Ships Built? Discover the Construction & Engineering Behind these Treasures of the Sea

Have you at any point gazed at a huge cruise ship and considered how it was able to remain above water? Many cruise ships constantly travel to Alaska and Hawaii during the summer. During the winter, an abundance of cruises are available to go to Mexico, the Caribbean, and other locations in the South Pacific. Considering the continuous growth & development of the cruise sector, the several types of materials & metals required for assembling the ships, we thought it's worth taking a deeper dive here into the full construction involved.

The Components used for Construction of Cruise Ships

Every one of the heaviest sections of the ship like the powerplants, engines, ballast, water, and fuel tanks are kept at the lower part, 20% from the bottom of the ship in order to ensure the ship remains upright. Ideally, underneath the waterline which is used to make sure the ship remains steady and reduces the center of gravity. The 80% left over part of a regular cruise ship is created to be employed by passengers, which is light and open as it can be.

Looking higher up the cruise ship, you will realize that it gets more open and lighter in weight which is aimed at limiting the weight. The pool is only an exception. Apart from being extremely heavy, you can only get the best view at the top which makes the swimming pool located there.

The materials are properly chosen and are also based upon your location in the vessel. Close to the upper part of the ship, the prominent selections are high durable steel and aluminum. This provides the best available strength-to-weight ratio. Carbon fibers and fiber strengthened plastics are now been tested on more recent vessels as these materials are quite new and pretty uncommon. Getting a little lower, hotter rolled steels would be found. The crucial features here are heavyweight and durability which allows designers to employ thicker materials in this section.

The part that requires more strength, usually very complicated and developed first is the hull. It has the shape of a massive metal tube with several supports and leak-proof rooms inside it. This is vital because several stresses are exerted by the ocean on ships. Tubes are part of the shapes that have the most mechanical strength in the world but it gets weaker when holes are drilled into it like it is required for doors. This makes the door locations to be planned properly which is then strengthened by the structural support.

The massive structure is then fitted at the top after the completion of the hull. But this massive structure spaces of the entire cabin and activity area remains open. The cabin and other components are assembled in a contained environment that is not on the ship just like a car. After the construction of these flat-packed spaces, they are then integrated into the massive structure and installed like the plugging in a huge LEGO.

Several facades are present in many of the rooms looking into the ship. Considering those attractive sheets of surfaces of wood and marble, they are actually artificial wood on light, durable and frames of metal or thin stony sheets. Stainless steel and ceramics are also very common since they are very durable, cost-effective and incombustible.

Crucial Ship Rigging Equipment

Rigging is an important component of ship employment. Riggers set up ships’ parts & equipment for transports by the crane, hoists or other material handling equipment.

When considering ship rigging tools, you’ll be majorly getting involved with hooks, eye straps, swivels, pulleys, and other devices. Even though many of these materials are quite simple and modest. An effective rigging task can only be achieved with all these tools working collectively.

In regards to lifting tools, you typically would be looking at chokers, hooks, halyards, eye straps, connectors, blocks, swivels and many more. Each of these small devices plays a major part in pulling off a rigging job.

Other components such as the ropes and dynamometers are also very crucial when performing rigging and lifting tasks.

The demand for guy wire or wire rope in the marine industry is numerous whether during the start of the construction process of the ship or when harboring the ship at the docks. Heavy strains, pressure and loads are usually involved irrespective of what the wire ropes will be used for. A thin rope can obviously not be able to harbor a ship at the docks. Lifting materials are usually developed to carry out numerous tasks that involve heavy pressure and strain which makes it a top choice for the marine industry.

During the start of a marine procedure, the wire ropes are also employed to build the ships since it is usually employed with cranes when performing lifting tasks in the engineering and construction industry. Ships developed with solid and enormous materials and the best equipment that can help to move them around in a building site is by using wire ropes.

Apart from the lowering and lifting jobs carried out when building a vessel, cranes found in the docks and on the ships are also beneficial when transferring cargos. Concerning the point mentioned above, the best choice for transferring heavy loads is still the rope.

The components are as well beneficial in securing vessels at the docks. The weight of the ships is without any doubt very heavy and one of the tools that can position them securely without floating off is the rope.

The ready-made strategy is usually not far-fetched however, the monstrosity of the scale makes the construction of a heavy ship an enormous task. The construction process incorporates many years of preparation and design procedure along with millions in cost of materials and workers. Ships that are as enormous as the Quantum of the sea with a construction cost of about $1.6 billion. However, in the end, a beautiful transportation masterpiece arises that can be appreciated for years to come.

Hull Design: Engineering a Smoother Ride

Download video, related videos.

Engineering Department Onboard Cruise Ships – A Detailed Guide

What comes to mind when we hear the word “ Cruise Ship ”?

Big, behemoth and beautiful seagoing vessels which resemble floating hotels, giant casinos, or floating theme parks?

Well, as glamorous as they may seem from the outside, a lot of discipline, punctuality & hard work goes into providing a unique experience of luxury, quality, comfort, fun, relaxation, safety & security for guests vacationing on them.

Many crew members work long shifts, putting in hours of hard work along with dedication, efficiency and attention to detail to ensure that guest needs are attended to as quickly as possible and that they only have the best experiences and the happiest memories of their limited time onboard.

An average-sized cruise ship typically has a passenger capacity of around 2000-2500 and a crew complement of 600-1000, which is predominantly divided amongst the following departments, viz., Deck, Engineering, Food & Beverage, Housekeeping, Sanitation, Guest Services, Laundry, Spa, Medical, Entertainment, Photography, Merchandise, IT, HR, Shore Excursions , Cruise Staff and Youth/Children’s activities.

Let me give a brief introduction of the roles and responsibilities of the various departments on board.

The Deck department is headed by the captain and has command of the ship. Safety, Security and Environmental departments also come under their purview.

They are also responsible for drills related to safety, security, pollution prevention and also related shipboard training of the crew-members.

In some companies, the carpentry and upholstery department also come under the Deck department.

The food and Beverage department , as the name suggests comprises everything that is food-related or culinary in nature. All the restaurants, galleys, chefs, stewards, bakery and bar department come under it.

The housekeeping department takes care of the upkeep of the guest & officer cabins and public spaces onboard whereas the sanitation department ensures that all the shipboard areas are sanitized and germ/infection-free.

The laundry department handles the clothes and linen of the entire ship and the Spa department offers personal care, grooming and wellness services for the passengers. In many cruise lines, these can also be availed by senior officers.

Food and Beverage, Housekeeping, Sanitation, Laundry and Spa all have their assigned managers who report to the Hotel Director, who is the overall in charge of all Hotel operations, of which these departments are part.

Entertainment, Photography, Merchandise, Shore Excursions, Guest Services, Cruise staff and Youth/Children’s activities departments come under the purview of the Cruise Director.

While Entertainment is responsible for casinos, stage shows, theatre screenings, stage & theatre technicians and equipment, the Photography department, as the name suggests, helps the guests to capture their precious moments onboard as photographs and make lasting memories through them with family & friends, while enjoying various activities and events.

The merchandise department is in charge of all the retail shops onboard which sell exotic items and articles such as jewellery, goodies and memorabilia to guests. They also run crew shops onboard which sell articles of everyday use and utility to crew-members, such as toiletry items, medicines and snacks.

Shore Excursions department’s job is to make the shore-side trips of the guests to exotic destinations at various ports of call, as easy, fun, safe, adventure-filled, inexpensive and entertaining as possible.

Cruise staff focuses on fun activities, trivia, games & competitions for the guests and crew alike, whereas Youth and Children’s activities focus specifically on youth and children’s entertainment and even provides day-care services for children, especially toddlers.

The guest services department is the interface between the guests and the ship staff/crew. Their job is similar to the job of the hotel front desk or reception. Any service requests such as cabin service requests as well as complaints such as a leaky cabin faucet etc. are made by the guests through them.

It is their duty to take these requests and/or complaints and pass them on to the concerned departments for action/rectification, provide feedback to the guests and assist them with any further follow-ups if required.

All the above have their specific line managers who report to the Cruise Director. The roles and responsibilities of some departments though can vary slightly from company to company.

In addition to the above departments, Medical, Information Technology and Human Resource are independent departments who have their own heads and report directly to the captain and the company.

The Medical department typically has 3 to 4 doctors and a similar number of nurses who work in shifts. It is headed by a senior doctor. They cater to both passengers and crew requiring medical assistance, at separate timings during the day. They are also the first responders for any medical emergency onboard.

The Information Technology department is responsible for all the computers, servers, programming, LAN, Ethernet, Wi-Fi, related hardware and software on board. Any network-related maintenance and troubleshooting onboard are carried out by them.

The Human Resource department is responsible for the orientation and familiarization training of new employees. They are also responsible for crew training pertaining to company culture and tradition, policies, leadership skills and management. Any conflicts and complaints onboard, inter-departmental as well as intra-departmental, are handled by the HR department, in conjunction with other departments. Final decisions with regards to re-employment and termination of crew members are taken by the HR department, once again after consultation with other concerned departments.

The Engineering Department Of Cruise Ship

After a brief introduction to the roles and responsibilities of various departments onboard cruise ships, let us now focus on the main topic of our discussion in this article, the Engineering department , which covers all the technical & environmental operations of the vessel.

This department is headed by the Chief Engineer. The Staff Chief Engineer, Hotel Services Engineer, HVAC Engineer & the Chief Electrician, who are in charge of different engineering subdivisions, report to the Chief Engineer.

These subdivisions are – Main Plant & Environmental Engineering, Hotel Engineering, HVAC & Electrical/Electronics.

Let us look into each: –

Main Plant & Environmental Engineering

This subdivision is headed by the Staff Chief Engineer who, in turn, is subordinated by the senior watchkeepers (2nd Engineers), the First Engineer and the Environmental Engineer.

There are usually three watchkeeping teams, each headed by a senior watchkeeper and comprising of junior watchkeepers (3rd or 4th Engineers) and a motorman.

On cruise ships, there are thousands of guests on board at any given time and there could be guest complaints requiring the immediate attention of the technical department, at any time of the day or night, such as a vacuum toilet not working, a leaky shower or a broken sprinkler head etc.

The engine control room acts as not only a control centre for engine-room machinery but also as a communications centre where all the complaints/malfunctions or incidents related to technical equipment are communicated by other departments at any time as they occur.

In the above cases, it is the job of the senior watchkeepers who man the engine control room to attend such calls and communicate the concerns/complaints to the concerned in-charges, within the Engineering department.

Any hotel equipment related complaints, leaky cabin faucets or sprinkler heads, malfunctioning vacuum toilets to the Hotel department, any electrical equipment malfunctions to the Chief Electrical engineer and any AC/ ventilation related complaints to the HVAC engineer.

Therefore, unlike many cargo ships, the engine control room cannot at any moment, be left unmanned in UMS mode. The watchkeeping teams ensure that the engine room and the engine control room are manned 24 hours.

Each watchkeeping team also has certain assigned machinery under their responsibility. For example, one watch may be responsible for fuel oil system and purifiers, another may be assigned boiler & compressors, and the third may be in charge of freshwater generators and water treatment.

It is their responsibility to carry out maintenance as per PMS on their assigned equipment every day, in addition to their watchkeeping responsibilities.

This, in turn, is carried out ensuring that at no time the maintenance work affects the efficiency of watchkeeping duties. For any complicated maintenance requiring more time and manpower, they are provided assistance by the main plant team.

The First Engineer heads the main plant team and is the overall in-charge of engine-room machinery. He has a team of mechanics, fitters and wipers under him who help him in carrying out routine maintenance and overhauls of engine-room machinery.

All maintenance activities on the main diesel generators, engine-room pumps, heat exchangers, major repairs on boilers, preparation for boiler surveys, bunkering and any pipeline modifications/repairs within machinery spaces are handled by the main plant team.

The Environmental Engineer is responsible for the wastewater treatment plant and garbage-handling equipment and has designated motormen under him.

The sewage treatment plant and related pumps and equipment, black water units, screen presses, incinerators and food waste processing equipment come under his KRA.

Hotel Engineering

It is the name given to the subdivision of the Engineering department which deals with all the machinery that are not part of engine-room operations.

The Hotel Services Engineer helms it and is supported by assistant hotel service engineers, plumbers, fitters and a water technician.

Their responsibilities include safety equipment such as lifeboats & davits, sprinkler system, hydraulic side-shell doors, watertight doors , vacuum toilets, freshwater distribution lines in the accommodation and hotel machinery such as coffee-makers, ice-cream vending machines etc.

They are also responsible for chlorination and maintenance of all the swimming pools on board and in some companies, also for potable water treatment and chlorination. This is handled exclusively by the water technician who reports to the Hotel services engineer.

HVAC stands for Heating, Ventilation and Air-Conditioning. It is helmed by the Chief AC Engineer, and he, in turn, is assisted by Assistant AC Engineers, AC Technicians, fitters and wipers.

Their areas of responsibilities pertain to the operation and maintenance of the main AC Chillers, which provide air conditioning all over the ship, Air handling Units, Ventilation fans, Refrigeration Machinery, Cold rooms, Chilled & heated water system and related heat exchangers.

Electrical Department

It is helmed by the Chief Electrical Engineer, who is sub-ordinated by the First electrician, Electronics engineer, 2nd electricians and assistant electricians.

It is one department that has a large scope of work as electrical installations and equipment are everywhere on the ship, many of them requiring everyday checks and maintenance, both regular and breakdown.

Almost all passenger vessels have high voltage installations, mostly 6.6 kV or 11 kV. This is because, since current demand is high, a higher voltage is adopted so that conductor size, and consequently electrical losses, can be reduced.

The high voltage switchboards require special training and procedures, with regards to electrical safety, which cruise ship electricians are equipped and certified with.

They are also responsible for electrical propulsion systems, which propel most cruise ships, related transformers and converters.

Therefore, as we saw, from propelling the ship to wonderful destinations, providing power to the entire ship, maintaining passenger comfort and hygiene whilst ensuring that they have uninterrupted enjoyment onboard and complying strictly with safety and pollution prevention regulations, the diverse roles and responsibilities that the Engineering department takes up, makes them critical for cruise ship operations.

You might also like to read:

- Top 10 Most Expensive Cruise Ships in 2021

- A List of Unique and Interesting Marine Careers

- 50 Marine Careers Essential Guide

- What is Naval Architecture: Careers, Courses And Jobs For Naval Architects

- A Career in Logistics: A Detailed Guide

Disclaimer : The information contained in this website is for general information purposes only. While we endeavour to keep the information up to date and correct, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability or availability with respect to the website or the information, products, services, or related graphics contained on the website for any purpose. Any reliance you place on such information is therefore strictly at your own risk.

In no event will we be liable for any loss or damage including without limitation, indirect or consequential loss or damage, or any loss or damage whatsoever arising from loss of data or profits arising out of, or in connection with, the use of this website.

Do you have info to share with us ? Suggest a correction

Related Articles

A Woman Chief Engineer from Brazil Describes Her Interesting Life

Marine Insight Launches “Know the Sea” Campaign

Adopting a No Blame Policy On board Ships

About Author

Ramanan Sethuraman is a marine engineer who has over a decade of experience in shipping. Having started his career with cargo ships, he later shifted to passenger liners and have sailed with reputed cruise lines. In his free time he likes reading, writing, sports and travelling.

Read More Articles By This Author >

Daily Maritime News, Straight To Your Inbox

Sign Up To Get Daily Newsletters

Join over 60k+ people who read our daily newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

BE THE FIRST TO COMMENT

Leave a reply.

Your email address will not be published. Required fields are marked *

Subscribe to Marine Insight Daily Newsletter

" * " indicates required fields

Marine Engineering

Marine Engine Air Compressor Marine Boiler Oily Water Separator Marine Electrical Ship Generator Ship Stabilizer

Nautical Science

Mooring Bridge Watchkeeping Ship Manoeuvring Nautical Charts Anchoring Nautical Equipment Shipboard Guidelines

Explore

Free Maritime eBooks Premium Maritime eBooks Marine Safety Financial Planning Marine Careers Maritime Law Ship Dry Dock

Shipping News Maritime Reports Videos Maritime Piracy Offshore Safety Of Life At Sea (SOLAS) MARPOL

WAIT! Did You Download 13 FREE Maritime eBooks?

Sign-up and download instantly!

We respect your privacy and take protecting it very seriously. No spam!

WAIT! Did You Download 12 FREE Maritime eBooks?

Day of the seafarer offer is live , day of the seafarer offer is live.

Best viewed in portrait mode

Important Updates from Cruise

11.14 2023 Update:

On November 13, the Cruise Board held its regularly scheduled quarterly meeting at Cruise headquarters in San Francisco. The Board took further steps to enhance safety and transparency as we work to build a better Cruise, including:

Craig Glidden to assume the role of Chief Administrative Officer for Cruise

As we posted in our blog last week, we have initiated workstreams in four key areas to identify potential improvements to how we operate. We are pleased that Craig Glidden, GM’s Executive Vice President of Legal and Policy and Cruise board member, will be expanding his support of Cruise and working closely with Cruise CEO Kyle Vogt and the Cruise Senior Leadership Team to oversee the workstreams around Transparency and Community Engagement. Cruise’s Legal & Policy, Communications, and Finance teams will report directly to Craig, and he will assume the title of Chief Administrative Officer for Cruise. He will continue in his current role at GM. Cruise will benefit from leveraging Craig and GM’s experience and best practices when it comes to transparency and engagement around safety.

Retention of an independent expert to conduct a comprehensive safety assessment

We announced last week that Cruise will hire a permanent Chief Safety Officer who will report directly to Kyle. In addition, the Cruise Board will retain a third-party safety expert in the coming weeks to perform a full assessment of Cruise’s safety operations and culture. These independent findings will help further guide and inform the work we have initiated.

Expansion of Exponent’s scope

Cruise previously hired the independent, third-party engineering consulting firm, Exponent, to conduct a technical root cause analysis of the October 2 incident. That work is ongoing, and the Board plans to expand Exponent’s remit to include a comprehensive review of our safety systems and technology.

Voluntary pause of supervised and manual operations

On October 26, we announced a pause of all our driverless operations while we take time to examine our processes, systems, and tools and improve how we operate. In the coming days, we are also pausing our supervised and manual AV operations in the U.S., affecting roughly 70 vehicles. This orderly pause is a further step to rebuild public trust while we undergo a full safety review. We will continue to operate our vehicles in closed course training environments and maintain an active simulation program in order to stay focused on advancing AV technology.

Cruise is dedicated to rebuilding trust and operating at the highest standards of safety. We are committed to keeping our customers, regulators, and the public informed throughout this process.

We believe that over time autonomous vehicles can significantly reduce the number and severity of car collisions, including the more than 40,000 deaths on U.S. roads each year. This is what motivates our work. We also know we have a responsibility to operate at the highest standards of safety, transparency and accountability.

We recently announced a pause of all our driverless operations while we take time to examine our processes, systems, and tools and improve how we operate. During this time we plan to seek input from our government and agency partners and other key stakeholders to understand how we can be better partners.

Today we are sharing updates on some of the initial steps we have taken.

Issued a Voluntary Software Recall

As part of our larger efforts to assess, identify and remedy issues as we work with NHTSA and other regulators, we have issued a voluntary recall of part of our AV software based on a new analysis of our AV’s post-collision response on October 2. The recall addresses circumstances in which the Cruise collision detection subsystem may cause the Cruise AV to attempt to pull over out of traffic instead of remaining stationary when a pullover is not the desired post-collision response.

We issued the recall through a 573 NHTSA filing, which is the standard protocol for a company looking to notify consumers of hardware or software safety issues that require a remedy. We have also developed a software update that remedies the issue described and have deployed it to our supervised test fleet, which remains in operation. We’ll deploy the remedy to our driverless fleet prior to resuming those operations.

Although we determined that a similar collision with a risk of serious injury could have recurred every 10 million - 100 million miles of driving on average prior to the software update, we strive to continually improve and to make these events even rarer. As our software improves, it is likely we will file additional recalls to inform both NHTSA and the public of updates to enhance safety across our fleet.

Announced a Chief Safety Officer (CSO) Role

Cruise is conducting a search to hire a Chief Safety Officer who will report directly to the CEO. In the meantime, Dr. Louise Zhang, VP of Safety & Systems, will assume the role of Interim Chief Safety Officer and oversee our safety review & investigations.

Retained Third-Party Law Firm to Review October Incident

The Cruise Board retained law firm Quinn Emanuel to examine and better understand Cruise’s response to the October 2 incident, including Cruise’s interactions with law enforcement, regulators, and the media. This outside review will help us learn from this incident, strengthen our protocols, and improve our response to these types of incidents in the future.

Appointed Exponent to Conduct Technical Root Cause Analysis

In addition to our cooperation with investigations from the California Department of Motor Vehicles (DMV) and National Highway Traffic Safety Administration (NHTSA), we have hired an independent, third-party engineering firm to perform a technical root cause analysis of the October 2 incident. We will incorporate their findings into our safety and engineering processes.

Initiated Additional Workstreams

We have identified four key areas of potential improvements to how we operate and have assigned leaders to investigate each one and complete follow up actions.

Safety Governance: We are taking a deep look at our overall safety approach and risk management structures to ensure we are built and positioned to enable continuous improvement.

Safety and Engineering Processes: We have advanced tools and processes in place and are committed to further upgrades wherever warranted. We are comprehensively reviewing all of our safety, testing, and validation processes and will add or modify processes where there is room to improve.

Internal & External Transparency: We understand that transparency is key to trust, especially in an emerging industry like ours. We are committed to improving how we communicate with the public, our customers, regulators, the media, and Cruise employees.

Community Engagement: We also understand the importance of collaborative partnerships. To realize the community benefits of autonomous driving, we need to do a better job engaging with our stakeholders and soliciting their feedback.

We are dedicated to building a better Cruise, and these initial actions are just some of the steps we’re taking as we listen, learn, and improve. We are committed to keeping our customers, regulators, and the public informed throughout this process.

- All Job Positions

- Marine Operations

- Recruitment process

Our Engine Team is a FUN bunch who get a kick out of pistons, pumps, and oil-water separators and enjoy getting their hands dirty to ensure the safe and smooth operation of the onboard propulsion systems, engines, waste disposal systems, electrical and fire systems, air conditioning, and mechanical equipment.

Set sail with Carnival Cruise Line and help us bring the FUN to life aboard one of our fantastic vessels as a 2nd Engineer. You will play a vital part in technical operations and report to the Staff Chief Engineer and Chief Engineer. You will consistently monitor, control, and troubleshoot all engine machinery equipment while being on watch in accordance with our policies, procedures, and safe working practices, promoting a strong safety culture and adhering to all environmental policies and procedures at all times. Your duties include:

- Ensuring compliance with Engine Room Resource Management standards

- Ensuring c ompliance with Environmental/Health and Safety Policies and procedures, MARPOL and SOLAS Policies

- Ensuring c ompliance with all relevant flag states and classes as well as other applicable regulations

- Carry out the Engine watch with particular attention to: the functions and operation of the main engines, auxiliary engines (where applicable), and power generation; the operation of all M/E and A/E ancillary equipment (where applicable); condition of bilges and bilges tanks; and piping integrity

- Fulfill and carry out the Environmental Compliance Plan

- Maintenance and repair (but not limited to) of the following: bilges and bilges tanks; chemical analysis and treatment of boiler water, cooling water, A/C pre-heating, and re-heating water systems; lifeboats, tender boats, rescue boats, and file rafts winches; Purification system; Lubrication system; Hydraulic system; Electric propulsion motors (where applicable); Boiler and Steam Plant; and HFO, MDO, LO purifier; consumption analysis calculations

- Bunkering and manning of HFO, MDO, LO operations

- HFO, Diesel, Oil, and Sludge Transfer Pumps and related systems

- Stabilizers, Thrusters, and AZIPOD systems

- Steering gear and related systems

- Pitch propeller controls and Propeller shafts (where applicable)

- Piping integrity

- Economizer and ancillary equipment

- Sooth blowing / Infrasonic system

- Provide continuous supervision to systems in temporary operation

- Ensure safety measures are implemented and functional

- Participate in drills and training

- Responsible for all watch monitoring data (sounding, counter, mass flow, grey and black water transfer log, etc.) recorded and filed as per SMS

- Ensure that all machinery assigned are in working order and in compliance with carrying out Environmental, Health, and Safety procedures; ensure maintenance is carried out at due intervals in accordance with planned maintenance and service requirements, and all related logs and records are updated

- Compile Monthly Condition Report and update equipment technical cards of machinery assigned to him and his watch subordinate

- Report any abnormal condition of the machinery assigned

- Keep up good communication and transparency between TMs within the Engine department

- Any additional assignment at the discretion of the Staff Chief Engineer or Chief Engineer

Minimum Requirements

- To apply for this role, you must hold an IMO Certificate, Regulation III/2, 2nd Engineer

- 3+ years of experience working as a watchkeeper

- Valid STCW certificates, as required for the position

Preferred Experience

- Experience working within a cruise ship environment is a plus

- 2nd Engineer experience or higher is a plus

Undergo assigned trainings to develop skills & knowledge for the future positions.

Report any equipment malfunction, difficulties & concerns to the supervisor on duty.

Follow additional duties, other than listed in the job description, assigned by management due to the operational needs/shortages/changes.

Ensure beverage stations are full at all times and cleaned daily.

Engage in light conversations with guests always greet them with a smile.

At least 5 years of experience in similar roles is required.

You must be proficient in both written and spoken English.

Minimum guest interaction might be required.

You must pass a Seafarers Medical Fitness Examination.

You focus on continuous improvement and collaboration.

2nd Engineer

Expedia Rewards is now One Key™

Elektrostal, visit elektrostal, check elektrostal hotel availability, popular places to visit.

- Electrostal History and Art Museum

You can spend time exploring the galleries in Electrostal History and Art Museum in Elektrostal. Take in the museums while you're in the area.

- Cities near Elektrostal

- Places of interest

- Yuri Gagarin Cosmonaut Training Center

- Central Museum of the Air Forces at Monino

- Peter the Great Military Academy

- Ramenskii History and Art Museum

- Bykovo Manor

- Balashikha Arena

- Malenky Puppet Theater

- Balashikha Museum of History and Local Lore

- Pekhorka Park

- Saturn Stadium

- Orekhovo Zuevsky City Exhibition Hall

- Noginsk Museum and Exhibition Center

Top things to know about Copilot+ PCs from Microsoft Surface, available today at Microsoft.com

- Microsoft Store Team

Available today, the all-new Copilot+ PCs from Microsoft Surface – Surface Laptop and Surface Pro – are thin, light and beautiful devices that help you do more of what you love. Whether it’s starting a new creative project, connecting with friends and family or pursuing a new business venture, these devices are designed to support your journey.

The new Surface Laptop and Surface Pro are Copilot+ PCs, which are the fastest, most intelligent Windows PCs on the market. They are available in four color options at an incredible value, beginning at $999 Estimated Retail Price (ERP) USD on Microsoft.com or at a Microsoft Experience Center .

Exclusively on Microsoft.com, customers can purchase Copilot+ PCs from Microsoft Surface with 64GB memory (RAM) configurations which offer more performance and multi-tasking:

- Surface Laptop (7 th Edition) , starting at $2,399.99 ERP USD in Black with a 13.8-inch Display, Snapdragon® X Elite (12 Core) Processor and 1TB SSD Storage.

- Surface Laptop (7 th Edition) , starting at $2,499.99 ERP in Black with a 15-inch Display, Snapdragon® X Elite (12 Core) Processor and 1TB SSD Storage.

- Surface Pro Essentials Bundle , starting at $1,144 ERP, get the most out of your Surface Pro with this bundle, saving on a Microsoft 365 subscription and Microsoft Complete Protection Plan. Plus, when purchasing the Essential Bundle, customers can take advantage of 20% off accessories including the new Surface Pro Flex Keyboard.

Read on for everything you need to know about the new Copilot+ PCs from Microsoft Surface.

Our three favorite things about the new Copilot+ PCs from Microsoft Surface: 1 – Designed for your everyday work and play

- Power through your day without a worry. The new Surface Laptop and Surface Pro are more powerful than ever with Snapdragon X Series Processors, providing faster performance and all-day battery life with a powerful Neural Processing Unit (NPU) for all-new AI experiences.

- Sleek design and colors that match your aesthetic. Thoughtfully designed with your everyday in mind, the thin, lightweight and ultraportable devices feature premium finishes. They come in four stunning colors – perfect for any style: classic Black, timeless Platinum, bold Sapphire, and the new and refreshing Dune [i] .

- Brighter, more immersive displays for ultimate viewing. We’re introducing a new OLED with HDR [ii] display to the new Surface Pro for a cinematic experience, and the Surface Laptop has a new HDR touchscreen display with razor-thin bezels. No matter what you watch or view, your content is going to look stunning.

- Everyday AI companion with the Copilot key. The Copilot app is just a click away with the Copilot key – one of the newest additions to Windows 11 keyboards on Copilot+ PCs.

2 – Exclusive AI experiences designed to empower creativity and productivity

- Express your creativity with Cocreator [iii] . Whether a seasoned artist or new to design, Cocreator simplifies image creation and photo editing with easy text prompts and natural inking using a Slim Pen [iv] on Surface Pro or touch on Surface Laptop. Exclusive to Copilot+ PCs, Cocreator lets you bring your ideas to life, and it works alongside you to iteratively update the image in real time. Cocreator is available in Paint – the app you’ve grown to know and love.

- No matter where you are, Live Captions keeps you better connected [v] . Available on Windows, Live Captions can quickly translate any live or prerecorded audio into English – and in real time. Connecting with friends, family and colleagues just got easier, and you’ll never miss a beat when watching your favorite international movies or TV shows.

- New and enhanced audio and video effects bring new meaning to ”camera ready.” Both device cameras are powered by new features to Windows Studio Effects. Powered by an industry-leading NPU, they help improve lighting, ensure you appear clear and crisp on video, reduce background noise and offer creative filters so you can express yourself on camera. Built to automatically improve video calls, it’s like having a studio ring light and microphone right on your Windows PC! And the Surface Pro’s ultrawide field-of-view camera keeps you, or the whole family, in focus, even as you move around your space.

- Recall (preview) coming soon: For the solo-preneur who has too many working files and emails to maintain organization, Recall helps you quickly find things you have seen on your PC, keeping all documents, images, websites, instant messages, emails and apps right at your fingertips. This experience comes with built-in privacy and security controls.

Learn how to unlock the best of the new AI-powered features on your Copilot+ PC .

3 – The all-new Surface Pro Flex Keyboard [vi] unlocks new levels of flexibility

Alongside the new Surface Pro, we are introducing the Surface Pro Flex Keyboard , unlocking powerful new levels of flexibility to effortlessly adapt to your work and play routines. Ready to attach to your Pro for the ultimate laptop set-up or detach for more flexibility and to support your creative workflows. It is built with extra carbon fiber layers for stability and has a larger, customizable haptic touchpad. With integrated pen storage, your Slim Pen is secure, charged and ready to go. Accessibility remains core to our approach, so we designed the new Surface Pro Flex Keyboard with a bold keyset option to reduce eye strain and assist people with low vision.

Discover, learn and buy with Microsoft Store

Shopping at Microsoft Store is all about ease and convenience. Whether the new Copilot+ PCs from Microsoft Surface, Copilot Pro, Xbox consoles and games, apps, movies and TV shows, we’ve got you covered. Don’t miss our top deals on your favorite TV shows like Rick & Morty: Seasons 1-7, Buffy The Vampire Slayer Complete Series, Sons of Anarchy: The Complete Box Set and so much more – available for up to 50% off for a limited time .

- Flexible payment options : Find a payment plan that works for you with options like PayPal Pay Later and Citizens Pay Line of Credit [vii] . It’s budgeting made easy.

- Online Trade-in Program : For a limited time, buy a new Copilot+ PC from Microsoft Surface and get extra cash back when you trade in an eligible device.

- Free and fast shipping with 60-day returns : Get your items quickly with 2–3-day shipping at no extra cost or minimum purchase required and enjoy the flexibility of 60-day returns on almost any physical product.

- 60-day price protection : Shop with confidence knowing you have 60 days of price protection from your delivery date. If the price drops or you find a lower price elsewhere, we’ll honor a one-time price adjustment.

You can also bet on Microsoft Store offering lots of great deals throughout the upcoming back-to-school season. Be sure to keep an eye on the deals page !

Available alongside Microsoft Surface today, are brand new Copilot+ PCs from the biggest brands: Acer , ASUS , Dell , HP , Lenovo and Samsung . Learn more from major PC manufacturers or visit leading retailers, including Best Buy .

[i] Colors available on selected models only. Available colors, sizes, finishes and processors may vary by store, market and configuration.

[ii] HDR requires HDR content and enabling HDR in device settings.

[iii] Microsoft account required.

[iv] Surface Slim Pen sold separately.

[v] Currently supports translation for video and audio subtitles into English from 40+ languages. See https://aka.ms/copilotpluspcs .

[vi] Surface Pro Flex Keyboard sold separately.

[vii] With approval of Citizens Pay Line of Credit at 0% APR and 12- or 18-month term. Subject to individual credit approval. See the Citizens Pay Line of Credit Agreement for full terms and conditions. Citizens Pay Line of Credit Account offered by Citizens Bank, N.A.

IMAGES

VIDEO

COMMENTS

Cruise is building the world's most advanced self-driving vehicles to safely connect people with the places, things and experiences they care about. Join us in solving the engineering challenge ...

By Rico Stenson, Engineering Manager. In January of this year, we introduced the Cruise Origin — the first purpose-built, fully driverless vehicle with a million-mile lifespan. It's self ...

Question regarding rough seas. I have sailed on Princess eg Ruby, Crown, Caribbean Princess etc. and Royal Caribbean, Navigator, Freedom, Independence, Vision. On Princess, the ships seem to flex left to right about the mid point. If you go down to Club Fusion (back of ship) the flex is even more extreme. Meanwhile the bow is rising up and down.

Today's mega cruise ships are engineering marvels. Onboard these floating cities, you can find anything from go-kart tracks to roller coasters, sky diving simulators, water parks, ropes courses, and more. On average, building a cruise ship takes two to three years, from the time the keel is laid to when the ship is launched. This does not include the time it took to design the ship.

88 results found. 5.13.2024. Cruise resumes supervised autonomous driving with safety drivers. 5.7.2024. Community-centered leadership: Rob Grant joins Cruise. 4.9.2024. Cruise resumes manual driving as next step in return to driverless mission. 3.25.2024. A letter from Cruise leadership.

Understanding Gratuities. Most first-time cruisers are confused on how the onboard gratuities work. While these are completely optional, they are somewhat expected. Each day of your cruise, you'll be charged a gratuity rate on a per person basis depending on your stateroom. Most of the time, you can expect this to be around $15 - $20 a day ...

Cruise ships are some of the largest ships on the water by volume and by the number of people carried, they have every other ship beat. The world's largest cruise ship, Harmony of the Seas, can ...

Cruise is building the world's most advanced self-driving vehicles to safely connect people with the places, things and experiences they care about. Join us in solving the engineering challenge ...

Cruise vehicles tell their wheels and other controls how to move along the selected path and react to changes in it. The result is a ride that's safe, efficient, and natural-looking to other drivers. Building safety into our technology. At Cruise, we aim to improve safety for all road users. Watch how a team of Cruisers who share a passion ...

Royal Caribbean's new Innovation Lab takes the ship design process to new heights by bringing the best creative minds and the latest technology together under one roof. From engaging virtual reality rooms to collaborative work spaces, the cruise line's new facility in Miami helps accelerate innovation and gives experts the ability to tangibly play and push the envelope before construction ...

Deck Officers on the Bridge of a Cruise Ship. For twenty-four hours each day, the bridge is occupied by two Deck Officers and two Able Seamen, traditionally in four-hour shifts. The main job of the Officer of the Watch is to monitor the ship's systems and surroundings, and to ensure that everything is running safely and smoothly.

The Celebrity Ascent cruise ship is one step closer to being built. At the Chantiers de l'Atlantique shipyard, Celebrity Cruises celebrated a milestone on Wednesday as it welded a ceremonial coin to a massive steel docking block forming the ship's keel, officially marking the beginning of construction on the fourth ship in the Edge Class - Celebrity Ascent. The forming of the ship's keel ...

Cruise discusses the software engineering & data collection from the three types of sensors, camera, radar, & LiDAR, used in our "Sensor Placement Tool" technology. ... Blog Post. 10.1.2020. How Cruise Uses Simulation To Speed Up Our Sensor Development. Rico Stenson Engineering Manager.

The 80% left over part of a regular cruise ship is created to be employed by passengers, which is light and open as it can be. Looking higher up the cruise ship, you will realize that it gets more open and lighter in weight which is aimed at limiting the weight. The pool is only an exception.

Videos. Hull Design: Engineering a Smoother Ride. Moving a cruise ship through the ocean takes more than just a powerful engine, it also takes sophisticated engineering and construction. From the biggest innovations to the smallest details, see how the hull design of Oasis of the Seas makes for a smooth ride.

An average-sized cruise ship typically has a passenger capacity of around 2000-2500 and a crew complement of 600-1000, which is predominantly divided amongst the following departments, viz., Deck, Engineering, Food & Beverage, Housekeeping, Sanitation, Guest Services, Laundry, Spa, Medical, Entertainment, Photography, Merchandise, IT, HR, Shore ...

Your marine engineering licence. Usually this is on the level of a bachelor of science. You can get it on a lower level, but this is preferred. Most cruise ships have electricians, so you usually just keep yourself busy with the other systems. Think steam, generators, propulsion engines, sewage plant, water desalinators, etc. Expect 10-12 hour ...

Craig Glidden to assume the role of Chief Administrative Officer for Cruise. As we posted in our blog last week, we have initiated workstreams in four key areas to identify potential improvements to how we operate. ... Cruise previously hired the independent, third-party engineering consulting firm, Exponent, to conduct a technical root cause ...

Experience working within a cruise ship environment is a plus. 2nd Engineer experience or higher is a plus. You will consistently monitor, control, and troubleshoot all engine machinery equipment while on watch duty, paying close attention to the main engines, auxiliary engines, power generators, M/E and A/E ancillary equipment, lubrication ...

Things to Do in Elektrostal. 1. Electrostal History and Art Museum. 2. Statue of Lenin. 3. Park of Culture and Leisure. 4. Museum and Exhibition Center.

A mix of the charming, modern, and tried and true. See all. Apelsin Hotel. 43. from $48/night. Apart Hotel Yantar. 2. from $28/night. Elektrostal Hotel.

Elektrostal. Elektrostal ( Russian: Электроста́ль) is a city in Moscow Oblast, Russia. It is 58 kilometers (36 mi) east of Moscow. As of 2010, 155,196 people lived there.

Cities near Elektrostal. Places of interest. Pavlovskiy Posad Noginsk. Travel guide resource for your visit to Elektrostal. Discover the best of Elektrostal so you can plan your trip right.

2 - Exclusive AI experiences designed to empower creativity and productivity Express your creativity with Cocreator. Whether a seasoned artist or new to design, Cocreator simplifies image creation and photo editing with easy text prompts and natural inking using a Slim Pen on Surface Pro or touch on Surface Laptop. Exclusive to Copilot+ PCs, Cocreator lets you bring your ideas to life, and ...