- Student Login

- Employer Login

Slippery When Wet: Warehouse Trip and Slip Hazards

Posted by: admin on August 16, 2018

A warehouse is a work environment, just like many other workplaces. But unlike offices and most indoor facilities, warehouses are more likely to have injuries and accidents. That’s why OSHA has regulations to help prevent slips, trips & falls. A number of factors contribute to this:

- Forklifts . With so many powered industrial trucks moving everywhere, accidents are more likely to happen – even though you can reduce those odds with training from us!

- Ignoring safety rules . The Occupational Safety & Health Administration (OSHA) sets guidelines and standards for workplace safety. When these rules are ignored or neglected, bad things happen. Sure, this can happen in any workplace, but when they occur in a warehouse, the potential damage is greater.

- Slips & trips . Warehouses come in many shapes and sizes – and also different floor surfaces. From refrigerated storage facilities to outdoor warehouses, workers need to be cautious at all times. OSHA slips, trips & falls regulations show how certain factors lead to workplace accidents and injuries.

For this article, let’s focus on warehouse trip and slip hazards. We’ll look at common causes for each type of hazard, and also offer some suggestions to keep your warehouse as clean, clutter-free, and safe as possible, based on OSHA slip, trips & fall prevention methods. We’ll also review some important OSHA slips, trips & falls statistics.

Preventing accidents and injuries is just one important part of a well-rounded forklift driving skill set. At CertifyMe.net, our training courses review important safety information, including the best ways to promote a safer, more efficient workplace. Sign up for our forklift training and become OSHA compliant today!

OSHA Slips, Trips & Falls Statistics: Surprising Data You Need to Know About

OSHA rules and guidelines, including slips, trips & falls regulations, are designed to make every workplace safer. Due to a lack of training and general awareness, accidents still happen – and more often than you probably think. According to recent OSHA slips, trips & falls statistics, nearly 1 in 5 fatal accidents at work were due to slips, trips & falls.

These accidents happen so often, OSHA has an acronym for OSHA slips, trips & falls statistics: STFs. However, with proper training and a basic understanding of your workplace, you can do your part to ensure OSHA won’t be investigating your company for slips, trips & falls.

Hazards Ahead: Trip and Slip Accidents in the Warehouse / How to Use OSHA Slip, Trips & Fall Prevention Methods for Added Safety

Trips, slips, and falls happen more often than you think. Aside from the obvious personal injury involved, there is also the possibility of an OSHA audit. These types of accidents can be extremely costly for individuals and companies. Knowing how trip and slip hazards happen is important for any warehouse. So is knowing what to do in order to avoid them.

Warehouse Trip Hazards

- Pallets . They’re one of the most common items in warehouses, so it’s understandable if a few get lost in the shuffle. Both empty and occupied pallets are serious trip hazards for anyone walking through a warehouse, including forklift drivers dismounted from the control cabin. OSHA slip, trips & fall prevention includes careful cleanup after any pallet breaks, and using pallets that are structurally sound.

- Merchandise . The typical warehouse contains thousands of pallets of products. If – when – a pallet spills or falls, literally hundreds of trip hazards are created right away. OSHA slip, trips & fall prevention methods indicate that safer product placement is an obvious way to avoid this, and forklift certification from CertifyMe.net can help in this regard.

- Bad visibility . If you can’t see a trip hazard, it’ll probably cause a fall. Ensure your warehouse has adequate lighting for everyone – forklift drivers included.

Warehouse Slip Hazards

- Water and ice . Slick surfaces and forklifts aren’t a good combination. The same goes for pedestrian foot traffic. Minor spills can become major problems in any warehouse, so make sure any spill or area with water is quickly cleaned up. Slippery surfaces make a good portion of OSHA slips, trips & falls statistics.

- Oil slicks . It’s not a problem for warehouses that use electric forklifts, but most standard forklifts eventually leak a little bit of oil. Tell your safety supervisor immediately about any oil slicks.

- Spilled product . For environments like frozen food distribution centers, spilled products pose serious slip hazards. Example: frozen beans on a warehouse floor act like miniature ball bearings. If any product is spilled in your warehouse, clean it up ASAP.

Don’t Trip During Your Forklift Certification Test and Get Up to Speed on OSHA Slips, Trips & Falls Regulations – Sign Up with CertifyMe Today!

Now that you know how to avoid certain trip and slip hazards, it’s time to gain a solid footing with your forklift certification. CertifyMe.net offers customized training packages for forklift drivers of any skill level. Sign up today – become OSHA compliant in no time. It’s the best move you can make for your forklift driving career!

From proper driving techniques to OSHA slip, trips & fall prevention, CertifyMe.net has everything you need to enjoy a safer workplace

Welcome to CertifyMe.net

CertifyMe.net has offered online forklift certification since 1999. With Our Convenient online program. your employess can earn their certification in an hour or less.

Browse Online Certifications:

- Forklift Certification

- Train the Trainer

- Aerial Lift Certification

- Sign Up Now!

This low-cost program can be compeleted anytime, anywhere!

- Read Our Reviews

888-699-4800 [email protected]

Get Started Now By Registering Your Company For Free!

- FREE 3 Year Renewals

- Instant Access 24/7

- Print Your Proof of Training

- OSHA Accepted Nationwide

*If you are an individual not currently employed by a company use your personal name in the 'Company Name' field.

- Toolbox Talks

Comprehensive Warehouse Safety Guidelines to Prevent Accidents and Injuries as per OSHA

- by Afnan Tajuddin

- Warehouse Safety

Warehouse workers play a vital role in the supply chain, ensuring that goods are stored, organized, and shipped efficiently. However, working in a warehouse environment comes with inherent risks and hazards that can lead to injuries and accidents if not properly addressed. In this comprehensive guide, we will explore the various hazards faced by warehouse workers and the necessary Warehouse Safety precautions to ensure their safety. We will also discuss the responsibilities of both employers and employees in maintaining a safe working environment. Let’s dive in!

Table of Contents

1. Warehouse Hazards and Their Impacts

Physical hazards.

Physical hazards in a warehouse can result from the operation of heavy machinery, the use of forklifts, and unsafe storage practices. These hazards include:

- Falling objects: Improperly stacked materials or poorly secured loads can lead to falling objects, posing risks to workers below.

- Slip, trip, and fall hazards : Cluttered aisles, slippery floors, and uneven surfaces can cause workers to slip, trip, or fall, resulting in injuries.

- Forklift accidents: Forklifts are essential tools in a warehouse, but improper operation can lead to collisions, crushing incidents, or tip-overs.

- Pinch points and entanglements: Moving conveyor belts, machinery, or equipment can trap workers’ body parts, causing severe injuries.

Chemical Hazards

Chemical hazards in a warehouse arise from the storage and handling of hazardous materials. Some potential risks include:

- Exposure to harmful substances: Improper storage or handling of chemicals can lead to spills or leaks, exposing workers to harmful fumes or liquids.

- Fire and explosion risks: Combustible or flammable materials, if not stored correctly, can create fire hazards with potentially catastrophic consequences.

Ergonomic Hazards

Ergonomic hazards result from repetitive tasks, awkward postures, and manual lifting, leading to musculoskeletal disorders ( MSDs ). Common ergonomic hazards in a warehouse include:

- Improper lifting techniques: Frequent manual lifting of heavy loads can strain workers’ backs and result in back injuries.

- Awkward postures: Prolonged bending, reaching, or twisting can cause strain on the body and lead to discomfort and MSDs.

- Repetitive motions: Performing the same tasks repeatedly without sufficient breaks can cause strain on muscles and joints.

These hazards can have severe impacts on workers’ health and well-being, affecting their productivity and quality of work.

2. Precautions and Safety Measures

Forklift safety.

Forklifts are indispensable tools in warehouses, but their safe operation is critical to preventing accidents. Employers should:

- Ensure operators are trained and certified: Forklift operators must receive proper training and certification to operate the equipment safely.

- Conduct regular maintenance checks: Regular inspections and maintenance of forklifts help identify potential issues before accidents occur.

- Provide appropriate safety equipment: Forklift operators should wear personal protective equipment, such as gloves and eye protection.

- Prohibit smoking and open flames: Smoking and open flames should be strictly prohibited in areas where forklifts are operated or battery charging takes place.

- Ensure proper battery handling: Battery charging should only take place in designated areas, and employees exposed to battery acids should have access to eyewashing and safety showers.

Housekeeping and Cleanliness

A clean and organized warehouse is crucial for maintaining a safe working environment. To prevent accidents and injuries:

- Keep aisles and walkways clear of clutter and obstructions.

- Regularly inspect and maintain the warehouse for hazards.

- Address spills promptly and use warning signs if needed.

- Ensure proper lighting to enhance visibility.

Material Handling Safety

Safe materials handling practices are essential to prevent injuries from falling objects or improper storage. Employers should:

- Maintain safe clearances: Adequate aisle clearances and loading dock safety measures should be in place to prevent collisions and entrapments.

- Properly stack materials: Materials should be stacked evenly and straight, with heavier loads placed on lower or middle shelves to maintain stability.

- Use proper lifting techniques: Employees should be trained in proper lifting techniques to avoid back injuries and Musculoskeletal disorders (MSD).

- Keep work areas well-lit and clean: Proper lighting and well-maintained work surfaces help reduce the risk of accidents and improve overall safety.

Hazard Communication Safety

Proper communication and handling of hazardous materials are critical in a warehouse environment. Employers should:

- Maintain Material Safety Data Sheets (MSDS): Each chemical used in the facility should have an updated MSDS to inform workers of potential risks.

- Train employees on chemical hazards: Workers should be educated on the risks associated with the chemicals they handle and the appropriate safety measures.

- Provide spill cleanup kits: In areas where chemicals are stored, spill cleanup kits should be readily available to respond to potential accidents.

- Enforce the use of personal protective equipment: Proper PPE , such as gloves and goggles , should be provided and enforced to protect workers.

Personal Protective Equipment (PPE)

PPE plays a crucial role in safeguarding workers from various hazards. Employers should:

- Provide appropriate PPE: Employers should ensure that workers have access to the right PPE for the specific tasks they perform.

- Train employees on PPE use: Workers should receive proper training on the correct use and maintenance of their PPE.

- Store chemicals safely: Chemicals should be stored according to manufacturer recommendations and local or national fire codes.

By implementing these precautions, employers can significantly reduce the risk of accidents and injuries in the warehouse.

E mergency Action Plans and Evacuation

Emergency plans are vital for ensuring quick and efficient responses to potential hazards:

- Develop comprehensive evacuation procedures and emergency action plans.

- Conduct drills and training to familiarize employees with emergency protocols.

- Have designated emergency exits and ensure their accessibility.

3. Responsibilities of Employers and Employees

Both employers and employees share the responsibility of maintaining a safe and healthy warehouse environment. Each party has specific roles to play in ensuring workplace safety:

Employer Responsibilities

- Provide a safe working environment: Employers must identify potential hazards and take measures to eliminate or minimize them.

- Conduct regular safety training: Employers should ensure that all employees are adequately trained in the safe operation of equipment and handling of hazardous materials.

- Implement safety policies and procedures: Employers should establish clear safety guidelines and enforce their implementation.

- Provide necessary safety equipment: Employers must supply the appropriate PPE and safety tools to protect workers from potential hazards.

- Maintain compliance with OSHA standards: Employers should stay up-to-date with OSHA regulations and ensure their workplace meets all safety requirements.

- Encourage reporting and communication: Employers should encourage open communication between workers and management regarding safety concerns and incidents.

Employee Responsibilities

- Follow safety guidelines and procedures: Employees should adhere to all safety protocols and guidelines established by the employer.

- Use PPE as required: Workers must wear the necessary PPE when handling hazardous materials or operating equipment.

- Report safety hazards: Employees should promptly report any safety hazards or incidents to their supervisors or managers.

- Participate in safety training: Workers should actively engage in safety training programs and seek clarification if they have any questions.

- Promote a culture of safety: Employees should actively contribute to a safe workplace by maintaining clean and organized work areas and assisting in identifying potential hazards.

By working together, employers and employees can create a safe and productive warehouse environment for everyone.

4. Warehouse Safety Guidelines and Best Practices

General safety measures.

- Keep aisles and walkways clear: Clutter-free aisles and walkways prevent trip and fall hazards.

- Conduct regular equipment inspections: Regular inspections of machinery and equipment help identify and address potential issues.

- Promote proper ergonomics: Ergonomic workstations and proper lifting techniques reduce the risk of Musculoskeletal disorders (MSD).

- Display safety signs and labels: Clear signs and labels provide visual cues and safety reminders to workers.

- Provide first aid and emergency response: Having first aid supplies readily available and emergency response plans in place can save lives.

Proper Materials Storage

- Stack materials safely: Materials should be stacked securely to prevent falling hazards.

- Store hazardous materials separately: Chemicals should be stored away from flammable or combustible materials.

- Use appropriate storage equipment: Racks, shelves, and pallets should be sturdy and suitable for the materials they hold.

Manual Lifting/Handling Techniques

- Train workers in proper lifting techniques: Employees should be trained on how to lift and handle heavy objects safely.

- Use mechanical lifting aids: When possible, mechanical lifting equipment should be used to reduce the risk of injury.

- Avoid overexertion: Workers should know their physical limits and avoid pushing themselves beyond what they can safely handle.

Evacuation Plans and Procedures

- Develop and communicate emergency plans: Employees should know the evacuation procedures and assembly points in case of emergencies.

- Conduct periodic drills: Regular evacuation drills help ensure that all workers know how to respond during emergencies.

- Train employees in fire safety: Workers should be educated on fire prevention and how to use fire extinguishers.

5. Compliance with OSHA Standards

Voluntary protection programs.

OSHA’s Voluntary Protection Programs (VPP ) recognize employers and workers who have implemented effective safety and health management systems. Businesses that meet VPP criteria demonstrate exemplary safety practices and receive recognition for their commitment to workplace safety. Many warehousing companies actively participate in VPP and share their expertise to mentor other businesses.

Alliance Programs

Alliance programs allow organizations committed to workplace safety to collaborate with OSHA in preventing injuries and illnesses. Several alliances impact the warehousing industry, including partnerships with the Retail Industry Leaders Association, the Industrial Truck Association, and the International Warehouse Logistics Association . These alliances promote safety, provide resources, and support initiatives to improve warehouse safety.

6. Conclusion

Warehouse worker safety is a crucial aspect of maintaining a productive and efficient supply chain. Identifying and addressing hazards, implementing safety measures, and fostering a culture of safety are essential in ensuring the well-being of employees. Employers and workers must collaborate and take their responsibilities seriously to prevent accidents and injuries in the workplace. By complying with OSHA standards and best practices , warehouse operators can create a safe and supportive environment where employees can thrive.

7. FAQs (Frequently Asked Questions)

Q1: What are the common physical hazards in a warehouse? A1: Common physical hazards in warehouses include falling objects, slip, trip, and fall hazards, forklift accidents, and pinch points and entanglements.

Q2: How can forklift accidents be prevented in warehouses? A2: Forklift accidents can be prevented by ensuring proper forklift operator training, conducting regular maintenance checks, providing appropriate safety equipment, and enforcing safety regulations.

Q3: How can ergonomic hazards be minimized in a warehouse? A3: To minimize ergonomic hazards, warehouse operators can implement proper lifting techniques, provide ergonomic workstations, and encourage breaks to prevent repetitive motions.

Q4: What is the employer’s responsibility regarding safety in a warehouse? A4: Employers are responsible for providing a safe working environment, conducting safety training, implementing safety policies, and ensuring compliance with OSHA standards.

Q5: How can employees contribute to warehouse safety? A5: Employees can contribute to warehouse safety by following safety guidelines, using personal protective equipment, reporting safety hazards, and actively participating in safety training programs.

By prioritizing safety and implementing effective measures, warehouses can protect their workers and achieve higher productivity in their operations. Warehouse worker safety is a shared responsibility that requires continuous effort and commitment from all stakeholders involved. Let us work together to create safer warehouse environments for everyone.

Q6: What is the role of OSHA in warehouse safety?

A6:OSHA oversees workplace safety by setting and enforcing standards, conducting inspections, and providing resources to promote safe working conditions.

Q7: How can employees prevent musculoskeletal disorders (MSD)?

A7:Employees can prevent MSDs by using proper lifting techniques, utilizing ergonomic equipment, and taking periodic rest breaks.

Q8: What resources are available for warehouse safety?

A8: OSHA offers e-tools, publications, and alliances with industry associations to assist employers in improving warehouse safety.

Share this:

Leave a reply cancel reply.

- Wire Decking

- Loading Dock Ramps

- Dock Boards & Plates

- Dock Levelers

- Industrial Shelving

- Used Equipment

Slips, Trips and Falls: How to Avoid Warehouse Hazards

In movies, cartoons and comedy shows, you often see those signs that state “x number of days without an accident” and then someone gets hurt in a silly way and they change the number to zero.

In the real world, warehouse safety is no laughing matter. Warehouses can be hazardous places, and workers can be seriously injured if they are not following safety precautions.

Many work-related can be avoided with the precautions in place. So, before your next day of warehouse work takes place, make sure you know how hazards can be avoided in your warehouse.

The Banana Peel Effect

Slips and trips are some of the most common workplace accidents that can occur. It’s important to take time every day to survey the warehouse floors and clean up any debris, water or document any areas that may need repair in the coming days.

Some specific things to keep an eye out for include loose materials, liquids, sawdust, uneven flooring, cracks in the surface of flooring, boxes that are out of place, dark areas and other suspicious elements that may affect a person walking through the warehouse.

By taking the time to do this daily, and also train your warehouse staff to locate and clean up anything that’s out of place, you’ll prevent the majority of slips from happening in your warehouse.

Watching Out for More Than One Kind of Fall

Often, when thinking about workplace hazards, falling from an elevated place is one of the most commonly injuries thought of. A few months ago, we shared a guide for how-to fall safely in the warehouse. You can read that here .

But, there’s another type of fall that can be a common hazard in a warehouse: falling objects.

It’s important when stacking pallets and boxes on warehouse shelves and dock boards , that all items are placed on flat surfaces and stacked securely. This will help avoid boxes and other objects from falling.

However, it’s also important to train all warehouse employees to remain aware at all times, so they watch for potential falling objects and can react quickly in the event that something does fall.

What other hazards do you watch out for in your warehouses? What suggestions do you have for training employees to watch out for and react to workplace hazards?

About Murray MH Staff

Subscribe to our e-mail newsletter to receive updates.

Related Posts:

- Cutting Warehouse Energy Costs During the Winter

- 2015 Recap: What Changed in the Warehousing Industry?

- Everything You Need to Know About The Pallet Rack

- How the Increase in E-Commerce is Changing Warehouses

- Warehouse Metrics Everyone Should Measure

No comments yet.

Leave a reply click here to cancel reply..

Name (required)

Email (will not be published) (required)

Phone: 740-548-7269 Email: [email protected]

Find us on Site by: Torrch

Insights and advice about jobs and hiring in the Lehigh Valley.

How to prevent slips and trips in the warehouse.

- August 8, 2017

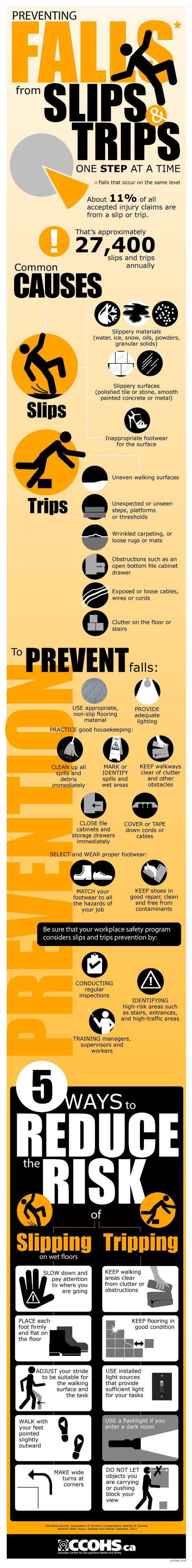

Infographic originally published on Pinterest by Canadian Centre for Occupational Health and Safety

Preventing slips and trips in the warehouse is everyone’s responsibility. Employers and employees must join forces to create and maintain a safe worksite.

As one of the top employment agencies in Lehigh Valley for warehouses, HTSS, Inc. understands the hazards present in this type of work environment. It’s not possible to eliminate any risk of injury, but most slips and trips are entirely avoidable.

Put Safety First in Your Warehouse

Provide training.

Despite your best efforts, some surfaces are inherently slick. In these situations, employees must be trained to properly move across the surface in a manner that reduces their risk of falling. Proper guidance can ensure they use a walking technique and speed appropriate for conditions.

Dress Appropriately

Employee attire is hugely important in a warehouse setting. If people aren’t dressed properly, they can sustain serious injuries, including trips and falls. Make sure employees are wearing appropriate apparel for the task at-hand — proper footwear is especially key — and don’t allow anyone not dressed appropriately to enter the work area.

Recognize Hazards

Even the most proactive employers can’t immediately spot all hazards, so workers must have the knowledge to identify issues. From cluttered stairways to loose cables, people must be informed of what constitutes a risk, and empowered to speak up if they even suspect a safety concern is present.

Accidents happen when people aren’t paying attention. Distracted employees are at a higher risk of slips and trips, because they aren’t focused on what they’re doing. Workers need to be fully present at all times, so multitasking doesn’t work in a warehouse setting.

Know the Risks

If they don’t know what’s at stake, it’s hard for some people to take safety warnings seriously. Workers need to be informed of the safety hazards present and the injuries that can stem from them. Employees are much more likely to follow the rules when all the facts are on the table.

Whether you’re searching for talent to staff your warehouse or looking for a fulfilling new warehouse gig, HTSS, Inc. is ready to assist. Our Lehigh Valley staffing firm is here for you, so contact us today to discuss your needs.

- HR & Management

As a staffing and recruitment professional for over 30 years, I have seen many changes in the industry. Over that time, I’ve witnessed a transformation in the way organizations view staffing services. Today, we see more and more companies using staffing services as a strategic tool, rather than just for temporary fill-ins.

At HTSS, Inc., our focus is on helping companies create proactive workforce plans. Our goal is to help our clients use staffing strategically to increase capacity, overcome hiring freezes, access specialized talent, better manage increased workloads, and enhance overall productivity.

For our candidates, we help to uncover truly rewarding job opportunities—jobs that are a match to each candidate’s skills, and jobs that offer key experience and growth potential.

We look forward to strengthening our relationships with our current clients and candidates, as well as forming new and exciting partnerships in the future.

Pat Howells President HTSS, Inc.

- Industry Updates

- Digital Conference

- Breathing Safely

- Handling & Storing

- Health & Wellbeing

- Industry Update

- Managing Health & Safety

- Plant & Machinery

- Slips, Trips & Falls

- Training & Development

Warehouse slips and trips hazards revealed

14 November 2022

OVER A quarter (26%) of warehouse workers have been impacted by slips, trips and falls in the past year, according to new research from Watco.

The survey of 250 facilities management professionals also revealed that almost half (42%) felt that wet and slippery surfaces, damaged floors and a lack of general maintenance pose the largest risk to the health and safety of employees at their site.

Sometimes a slip or trip can be relatively minor, but occasionally they can cause serious accidents and lead to costly claims. In fact, from 2017/18–2019/20, an estimated 971,000 working days were lost due to slip, trip and fall injuries in the UK, according to Health and Safety Executive statistics.

As winter approaches and it becomes prime time for slips, trips and falls, Scott Saunders, technical service manager at Watco shares his insights on how to prevent such hazards: “Whether you are in your workplace or at home, when the weather changes and suddenly snow, ice and rain gets traipsed around from outside, hazards become more common. But there are multiple ways businesses can ensure they are protecting employees.”

“To start with, it may seem obvious, but good housekeeping, like ensuring puddles are cleared up as soon as they are spotted or regularly dust mopping, is vital. For hazards which are a bit more difficult to clean – or even see - such as oil and grease spills from heavy-duty machinery, a degreaser is the perfect solution.

“Naturally, during the winter, rain, sleet and snow will end up in areas of your warehouse if you have movement into and out of the building or roller shutter doors in use. Using anti-slip solutions, such as Glass Reinforced Plastic (GRP) sheets, will provide added grip and an extra layer of protection to stop people falling when spills happen. GRP sheets come with the added benefit that when they are being applied, the area is out of action for minimal time because you don’t have to wait for it to dry.”

In addition, the survey found that over a third (34%) of facilities management professionals go over budget on urgent repair work to remove hazards and two thirds (64%) of facilities managers say a lack of general maintenance often, or occasionally, poses a safety risk within their business.

For more information on prevent slips this winter, download Watco’s free eBook here: https://www.watco.co.uk/help-advice/watco-ebooks/guide-for-safety-underfoot-ebook-part1

1/309 (1 to 10 of 3084)

- Dangerous ladders seized at port

- School fined after child is fatally injured

- HSE clamps down on South Yorkshire businesses

- 21 million pieces of PPE shipped from China

- Keeping it real

- First corporate manslaughter conviction

- Company fined after contractor falls from height

- Guidance issued on repurposing non-compliant PPE

- Inspection cuts will kill, warn union groups

- Security firm sentenced after employee attacked

- No related articles listed

- Digital Editions

- Free Subscription

1/2 (1 to 10 of 20)

- Farmer fined after escaped cow attack

- Engineering firm fined following worker’s death

- Employee attaching safety signs crushed to death

- Hospital staff left with life-changing conditions

- Lorry driver suffers life changing injuries

- Sheffield firm with poor welfare facilities sentenced

- Worker injured by 300kg batteries

- Worker fatally crushed by excavator attachment

- Farming company fined £320k following fatality

- Lung disease warning for kitchen worktop workers

01342 314300

NIOSH Science Blog: The Problem of Falls from Elevation in Construction and Prevention Resources

The current situation with falls.

In 2022 falls from elevation represented approximately 81% of all fatal and 20% of all nonfatal slips, trips, and falls for all industry workers (BLS 2023a, BLS 2023b). Many of these falls occurred in the construction industry, and significantly impact construction employers, workers, and their families. In fact, construction workers made up nearly half (49%) of all fatal occupational slips, trips, and falls (BLS 2023). Since 2013, construction workers have suffered approximately 300 fatal and 20,000 nonfatal fall-related injuries per year (CPWR 2024). Four out of 10 of the Occupational Safety and Health Administration’s (OSHA) top citations involved falls, including general fall protection, ladders, scaffolding, and fall protection training.

Roofing contractors, residential building construction, and commercial/institutional building construction had the highest number of fatalities in 2022 compared to previous years and other industries (CPWR 2024). In addition, approximately 70% of all fatal falls in construction occurred to those working for employers with less than 10 employees (CPWR 2024).

Causes of Falls

The causes of construction workers’ falls from elevation are complex and multifaceted. There are many different factors at play. In 2021, CPWR conducted a fall experience survey that found that insufficient or ineffective planning is a key underlying cause of falls.

In addition, lack of planning was associated with reduced likelihood of using fall protection. Using fall protection was 71% lower for workers whose employer did not do any planning. Approximately half (49%) of survey respondents said that no fall protection was being used at the time of the fall. Lack of fall protection is particularly problematic for small residential construction firms with fewer than 10 employees (CPWR 2022).

Ladders and Ladder Safety

Falls from ladders are a common cause of injury for construction workers (CPWR 2024). Employers should be familiar with safety and regulatory requirements before using a ladder, including:

Planning work tasks to eliminate or reduce the need to work at elevation.

Providing the right equipment. This includes alternative equipment for extended work periods at elevation, such as aerial lifts, supported scaffolds, or mast climbing platforms. If a ladder must be used, properly select the ladder for the location and height of the task and the weight of the worker. Ensure it is thoroughly inspected before each use.

Training all workers in a language they understand on the proper use, care, and inspection of each type of ladder being used.

A recent webinar hosted by CPWR – The Center for Construction Research and Training (CPWR) discussed ladder safety and ways to improve ladder design, usage, and training. The webinar included a panel of experts who conduct laboratory research on ways to prevent common ladder fall injuries, such as slipping off a ladder and falling with the ladder. The audio from the webinar is also available in Spanish .

Ladder Safety Resources

Ladder Safety App

National Ladder Safety Month website

ALI Training

ANSI blog on 5 most common causes of ladder incidents based on ALI study

OSHA Stairways and Ladders

OSHA Letter of Interpretation on three points of contact

Rescue Planning

Falls can occur quickly, even when all precautions are taken and using proper fall prevention and protection methods. Personal Fall Arrest Systems are a critical option to keep workers safe when performing tasks at heights, but rescue planning is essential.

If a fall occurs and a worker is suspended in a harness for more than a few minutes, a lack of circulation can cause unconsciousness, suspension trauma, and even death.

Every fall protection plan must include a rescue strategy to help workers after a fall and reduce fall-related injuries including suspension trauma even when using a Personal Fall Arrest System. Another finding from CPWR’s fall experience survey was that the odds of a fall being fatal were 76% lower for those who had self-rescue training compared to those who did not have this training. The rescue plan should be tailored to each jobsite and prioritize methods to preserve blood circulation for the worker. Ensure equipment for self-rescue is available, such as trauma straps and self-rescue harness units. The rescue plan should ensure other equipment is available, ready to be used, and in good condition, such as a ladder, aerial lift, or bucket truck.

Rescue Planning Resources

CPWR General Fall Protection Plan (English)

CPWR General Fall Protection Plan (Spanish)

OSHA Model Fall Protection Plan

OSHA Standard Interpretations – Rescue of a suspended worker following a fall event

CPWR Fall Rescue Planning Tipsheet

CPWR Fall Rescue Planning Tipsheet (Spanish)

The National Safety Stand-Down to Prevent Falls in Construction

The National Campaign to Prevent Falls in Construction (Falls Campaign) began in 2012 and was followed in 2014 by the National Safety Stand-Down to Prevent Falls in Construction (Stand-Down). The Falls Campaign idea originated with the National Occupational Research Agenda (NORA) Construction Sector Council. The Sector Council consists of industry experts on health and safety representing contractors, trade associations, labor, government, and academia. The National Institute for Occupational Safety and Health (NIOSH), OSHA, and CPWR are the Falls Campaign organizing partners. The Falls Campaign and Stand-Down are important events because of the high burden falls place on construction workers and their families.

Safety stand-downs originated in the military and are a time to focus on worker safety by stopping work and reinforcing the importance of fall prevention and fall protection.

This year’s Stand-Down will take place May 6-10, 2024. CPWR, NIOSH, and OSHA are hosting a virtual event on Tuesday May 7 th at 2 pm (Eastern Time) to educate employers and crew leaders on how rescue planning can save lives. Click here to register and submit a question in advance. Attendees will learn more about identifying a competent person to lead fall prevention and rescue planning, incorporating key components of a rescue plan into the pre-job planning process, and using FREE resources and templates to tailor your plans to each unique jobsite. The webinar will be in English with simultaneous translation into Spanish available.

On May 8 th at 2pm (Eastern Time) a second Stand-Down webinar presented entirely in Spanish will be hosted. Click here to register and submit a question in advance.

Hosting a Stand-Down

Thousands of companies have held fall safety stand-downs , reaching millions of workers across all 50 states and internationally. Industry and business leaders, universities, labor organizations, and community groups have all participated. In 2023, there were 3,554 stand-downs reaching more than 463,000 workers.

Construction employers and workers are invited to host a Safety Stand-Down or join one.

Your involvement can be as simple as sharing NIOSH, OSHA, or CPWR resources at your worksite. If you would like to host or join a free event that is open to the public, contact your Regional Stand-Down Coordinator . You can find resources to host a Stand-Down and activities at CPWR’s Promotion and Planning Page .

If you do participate in the Stand-Down, make sure you get a Certificate of Participation from OSHA. The certificates provide recognition for your event(s). After removing all personal information, CPWR used the data to evaluate and improve the Falls Campaign and Stand-Down every year. Previous evaluation reports and factsheets can be found on the Stop Construction Falls Evaluation page .

Stand-down Resources

About the Campaign

CPWR’S Planning and Promotion Page on StopConstructionFalls.com

Suggestions to prepare successful Stand-Downs

Highlights from previous Stand-Downs

OSHA Regional Stand-Down Coordinators

OSHA Certificates of Participation

Additional Tools and Resources

National Falls Campaign & Safety Stand-Down Website

CPWR Data Bulletin

Bilingual Fall Hazards & Prevention YouTube Playlist

Spanish Fall Safety YouTube Playlist (Prevención de caídas)

Christina Socias-Morales, DrPH is a Research Epidemiologist in the NIOSH Office of Construction Safety and Health.

Scott Earnest, PhD, PE, CSP, is the Associate Director for the NIOSH Office of Construction Safety and Health.

Jessica Bunting, MPH, is the Research to Practice Director at the Center for Construction Research and Training (CPWR).

Rosa Greenberg, MPH, is a Research Analyst in Research to Practice at CPWR

Scott Breloff, Ph.D. is a Senior Biomechanical Research Engineer in the Division of Field Studies & Engineering and the Co-Coordinator for the Construction Program in the Office of Construction Safety and Health at NIOSH.

Asha Brogan, MS, is a Heath Communication Fellow in the NIOSH Division of Field Studies & Engineering.

Douglas Trout, MD, MHS, is Deputy Director, Office of Construction Safety and Health at NIOSH.

Bureau of Labor Statistics (2023a). News Release National Census of Fatal Occupational Injuries in 2022. USDL-23-2615. December 19, 2023. Available from: https://www.bls.gov/news.release/pdf/cfoi.pdf .

Bureau of Labor Statistics (2023b). Number of nonfatal occupational injuries and illnesses involving days away from work, restricted activity, or job transfer (DART), days away from work (DAFW), and days of restricted work activity, or job transfer (DJTR) by event or exposure leading to injury or illness and industry sector, private industry, 2021-2022 (TABLE R64). November 8, 2023. Available from: https://www.bls.gov/iif/nonfatal-injuries-and-illnesses-tables/case-and-demographic-characteristics-table-r64-2021-2022.xlsx

CPWR (2024). Data Bulletin: Fatal and Nonfatal Falls in the US Construction Industry. The Center for Construction Research and Training. Silver Spring, MD. March 2024. https://www.cpwr.com/wp-content/uploads/DataBulletin-March2024.pdf.

CPWR (2022). Underlying Causes of Falls from Heights (Highlighted Findings from a CPWR Survey). The Center for Construction Research and Training. Silver Spring, MD. March 2022. https://www.cpwr.com/wp-content/uploads/RR-falls_experience_survey.pdf.

Post a Comment

Cancel reply.

Your email address will not be published. Required fields are marked *

- 50th Anniversary Blog Series

- Additive Manufacturing

- Aging Workers

- Agriculture

- Animal/Livestock hazards

- Artificial Intelligence

- Back Injury

- Bloodborne pathogens

- Cardiovascular Disease

- cold stress

- commercial fishing

- Communication

- Construction

- Cross Cultural Communication

- Dermal Exposure

- Education and Research Centers

- Electrical Safety

- Emergency Response/Public Sector

- Engineering Control

- Environment/Green Jobs

- Epidemiology

- Fire Fighting

- Food Service

- Future of Work and OSH

- Healthy Work Design

- Hearing Loss

- Heat Stress

- Holiday Themes

- Hydraulic Fracturing

- Infectious Disease Resources

- International

- Landscaping

- Law Enforcement

- Manufacturing

- Manufacturing Mondays Series

- Mental Health

- Motor Vehicle Safety

- Musculoskeletal Disorders

- Nanotechnology

- National Occupational Research Agenda

- Needlestick Prevention

- NIOSH-funded Research

- Nonstandard Work Arrangements

- Observances

- Occupational Health Equity

- Oil and Gas

- Outdoor Work

- Partnership

- Personal Protective Equipment

- Physical activity

- Policy and Programs

- Prevention Through Design

- Prioritizing Research

- Reproductive Health

- Research to practice r2p

- Researcher Spotlights

- Respirators

- Respiratory Health

- Risk Assessment

- Safety and Health Data

- Service Sector

- Small Business

- Social Determinants of Health

- Spanish translations

- Sports and Entertainment

- Strategic Foresight

- Struck-by injuries

- Student Training

- Substance Use Disorder

- Surveillance

- Synthetic Biology

- Systematic review

- Take Home Exposures

- Teachers/School Workers

- Temporary/Contingent Workers

- Total Worker Health

- Translations (other than Spanish)

- Transportation

- Uncategorized

- Veterinarians

- Wearable Technologies

- Wholesale and Retail Trade

- Work Schedules

- Workers' Compensation

- Workplace Medical Mystery

- Workplace Supported Recovery

- World Trade Center Health Program

- Young Workers

To receive email updates about this page, enter your email address:

Exit Notification / Disclaimer Policy

- The Centers for Disease Control and Prevention (CDC) cannot attest to the accuracy of a non-federal website.

- Linking to a non-federal website does not constitute an endorsement by CDC or any of its employees of the sponsors or the information and products presented on the website.

- You will be subject to the destination website's privacy policy when you follow the link.

- CDC is not responsible for Section 508 compliance (accessibility) on other federal or private website.

Moscow warehouse raid leads to dozens detained, checked for military service

I n the Moscow region, police and the Russian Guard raided a Wildberries warehouse in Elektrostal. Several individuals were detained and transported to the military registration and enlistment office.

Employees shared videos from the scene on the Elektrostal Wildberries company's internal channel. The warehouse employs thousands of migrants, and the Russian National Guard is verifying their work permits , residence permits, and military IDs.

Dozens detained

"Those lacking the necessary documents are placed into prison vans and taken to the military registration and enlistment office," reports Baza, noting that approximately 20 individuals were detained.

The Astra channel reports that police used sticks to subdue resisting workers.

"They are identifying individuals eligible for military service and those evading it. Those evading are taken away without consent. Resisters face police baton charges," said warehouse workers to Astra.

Authorities previously stated that efforts to "enhance control over the migrant influx" were expected to intensify, especially following an attack on Crocus City Hall.

According to Mash channel, 15 people were arrested during the raid; Astra reports that "dozens" were detained. In total, at least 5,000 workers underwent checks.

"Screenings of foreign nationals working in Russia and instances of aggressive xenophobia have increased following the terrorist attack on Crocus City Hall, attributed to citizens of Tajikistan," reports Deutsche Welle.

Security force raids at migrant gathering spots may prompt employers to strengthen employment conditions. The likelihood of conscripting these individuals for military service is diminishing—suspect persons are more likely to be deported, implying the Russian army won't expand using their contributions. The 'special operation' is also expected to change, according to the Brief channel.

Novaya Gazeta Editor Detained for Allegedly Discrediting Russian Military

Raid on shopping mall sees Russians finding "willing" recruits for the army

Finnish military strength questioned by Sweden: Is Helsinki prepared for invasion?

IMAGES

VIDEO

COMMENTS

That means preventing slips, trips, and falls is an ongoing process that relies heavily on employees being able to recognize related hazards. What Are OSHA's Trip Hazard Regulations? OSHA's primary standard for slip, trip, and fall hazards is the General Industry Walking-Working Surface standard (29 CFR 1910 Subpart D, which includes §1910.21-30).

Vehicle exhaust from engines running in a warehouse is a serious hazard that affects indoor air quality. This OSHA Safety and Health topic page dedicated to preventing the hazards of exposure to diesel exhaust. ... spills, and other hazards that could cause slips, trips, or falls. Where floors may be wet or slippery (e.g., due to high humidity ...

Make sure proper footwear is worn - Non-slip shoes with good traction protect workers from static electricity, falling objects, explosions, exposure to hazardous substances, and other risks. Maintain and improve floor quality - Modifying the floor space can go a long way to ensure safety from slips, trips, and falls.

high rates of slip, trip, and fall (STF) injuries. The National Institute for Occupational Safety and Health (NIOSH) recommends measures to ensure a safe workplace and prevent injuries. Figure 1. Spilled liquid on a floor that may cause slips. Preventing Slips, Trips, and Falls in Wholesale and Retail Trade Establishments Description of the Problem

hazards that could cause employees to slip, trip or fall. Proper work practices are factored into determining the time requirements for an employee to perform a task. Employees performing physical work have adequate periodic rest breaks to avoid fatigue levels that could result in greater risk of accidents and reduced quality of work.

Slippery When Wet: Warehouse Trip and Slip Hazards. A warehouse is a work environment, just like many other workplaces. But unlike offices and most indoor facilities, warehouses are more likely to have injuries and accidents. That's why OSHA has regulations to help prevent slips, trips & falls. A number of factors contribute to this: Forklifts.

Slips, Trips and Falls. NSC Stands with OSHA on Fall Safety. It may come as a surprise that the second leading cause of unintentional injury-related death is falls. In 2022, 46,653 people died in falls at home and at work, according to Injury Facts ®. For working adults, depending on the industry, falls can be the leading cause of death.

Slips. Slip and trip accidents happen for a number of reasons. The following model will help you understand the factors that can contribute to slip accidents and the action to take to prevent them . It is called the slip potential model. One or more of these factors may play a part in any slip accident. Slip potential model

Slip, Trip, and Fall Prevention | 5 Table 1. Slip, trip and fall (STF) workers' compen-sation claims by body part injured, 1996-2005. Body part n % of total STF claims Lower extremities 185 44.9 Upper extremities 69 16.7 Multiple body parts 67 16.7 Back/trunk 73 16.2 Head/neck 18 4.3 Unknown 60 12.7 Total 472 100.0 Source: Bell et al. 2008 ...

Slip, trip, and fall hazards: Cluttered aisles, slippery floors, and uneven surfaces can cause workers to slip, trip, or fall, resulting in injuries. Forklift accidents: Forklifts are essential tools in a warehouse, but improper operation can lead to collisions, crushing incidents, or tip-overs.

Slips, trips, and falls cause nearly 700 fatalities per year and many more injurious accident in the workplace according to the Bureau of Labor Statistics. There are three physical factors involved in slips, trips, and falls: friction, momentum, and gravity. Each one plays a role. Friction is the resistance between objects, momentum is affected ...

Eliminate the hazard Remove slip and trip hazards at the design stage such as eliminating changes in floor levels and installing more power outlets to avoid trailing cords. Substitution Replace flooring with a more slip-resistant surface. Isolation Prevent access to high risk areas, for example cordon off wet floor areas while ...

#10 Slips, Trips, and Falls. Slips, trips, and falls are extremely common in the workplace. Warehouse settings are no different. Walking across the warehouse floor does not seem like a hazardous task, but it can be if hazards are present that lead to slip, trips, and falls. Slip, Trip, and Fall Prevention

Slips and trips are some of the most common workplace accidents that can occur. It's important to take time every day to survey the warehouse floors and clean up any debris, water or document any areas that may need repair in the coming days. Some specific things to keep an eye out for include loose materials, liquids, sawdust, uneven ...

Preventing slips and trips in the warehouse is everyone's responsibility. Employers and employees must join forces to create and maintain a safe worksite. As one of the top employment agencies in Lehigh Valley for warehouses, HTSS, Inc. understands the hazards present in this type of work environment. It's not possible to eliminate any risk ...

Subscribe for free health and safety news and updates on this topic. HSE explains how to prevent slips and trips in the workplace. Looks at the causes of slips and trips and discusses how to prevent them.

Unlike most industrial injuries, slips, trips, and falls can happen to any employee, visitor, or contractor at your facility. Identifying hazards is sometimes difficult because they can occur at ...

Warehouse slips and trips hazards revealed. OVER A quarter (26%) of warehouse workers have been impacted by slips, trips and falls in the past year, according to new research from Watco. The survey of 250 facilities management professionals also revealed that almost half (42%) felt that wet and slippery surfaces, damaged floors and a lack of ...

In 2022 falls from elevation represented approximately 81% of all fatal and 20% of all nonfatal slips, trips, and falls for all industry workers (BLS 2023a, BLS 2023b). ... Douglas Trout, MD, MHS, is Deputy Director, Office of Construction Safety and Health at NIOSH. References. Bureau of Labor Statistics (2023a). News Release National Census ...

Nasarwanji MF, 2016. Contributing factors to slip, trip, and fall fatalities at surface coal and metal/ nonmetal mines. In: Paper Presented at the Proceedings of the Human Factors and Ergonomics Society Annual Meeting. Nasarwanji MF, Mayton AG, Pollard J, 2019. Why slips, trips, and falls are still A problem: a hazard assessment at surface mines.

1910.22 (a) (1) All places of employment, passageways, storerooms, service rooms, and walking-working surfaces are kept in a clean, orderly, and sanitary condition. 1910.22 (a) (2) The floor of each workroom is maintained in a clean and, to the extent feasible, in a dry condition. When wet processes are used, drainage must be maintained and, to ...

Police raided the warehouse of online retailer Wildberries in Elektrostal, near Moscow, on Friday morning, according to state-run news agency TASS, which attributed the action to ongoing attempts to tackle illegal immigration. "Scores of law enforcement officers entered the Wildberries warehouse in Elektrostal to conduct an illegal migration inspection," a law enforcement source told TASS ...

The warehouse employs thousands of migrants, and the Russian National Guard is verifying their work permits, residence permits, and military IDs. Dozens detained

PK !Ó !W Ü. [Content_Types].xml ¢ ( ÌšÛnÛ0 †ï ì ß ±bgëº!I/v¸Ú¡@» Ðl&qgË‚¥¤ÍÛOvNnàÔM( ¾ êØ$?ÑÁOVÔøæ)ϼ "*-ÄÄ ƒ¡ï ˆ‹$ ó‰ÿçþûàÚ÷"æ"áY!`â¯Aù7Ó·oÆ÷k Ê3ÖBMü…Öò3c*^@ÎUPH æά(s®Íe9g'Çÿø X4 ^±¸ „ èʇ?

Russian police have detained dozens of workers at a warehouse of the online retailer Wildberries on suspicion of breaking migration laws, state media reported Wednesday. Wildberries' press ...

Ukrainian military had 45 combat engagements with Russian forces near Bilohorivka of Luhansk region, Terny, Yampolivka, Rozdolivka and north to Vesele of Donetsk region, Klischiyivka of Donetsk region, Berdychi and Pervomayske of Donetsk region, Novomykhaylivka, Staromayorske of Donetsk region, south-west Bilohirya and north-west of Verbove of Zaporizhzhia region, - General Staff of Armed ...